Over-voltage protection arrangement having a horn gap located in an insulating housing having a deionization chamber for arc extinguishing

A technology for protection devices and spark gaps, which can be used in overvoltage arresters with spark gaps, emergency protection devices, spark gaps with auxiliary trigger devices, etc., and can solve problems such as destroying fuses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

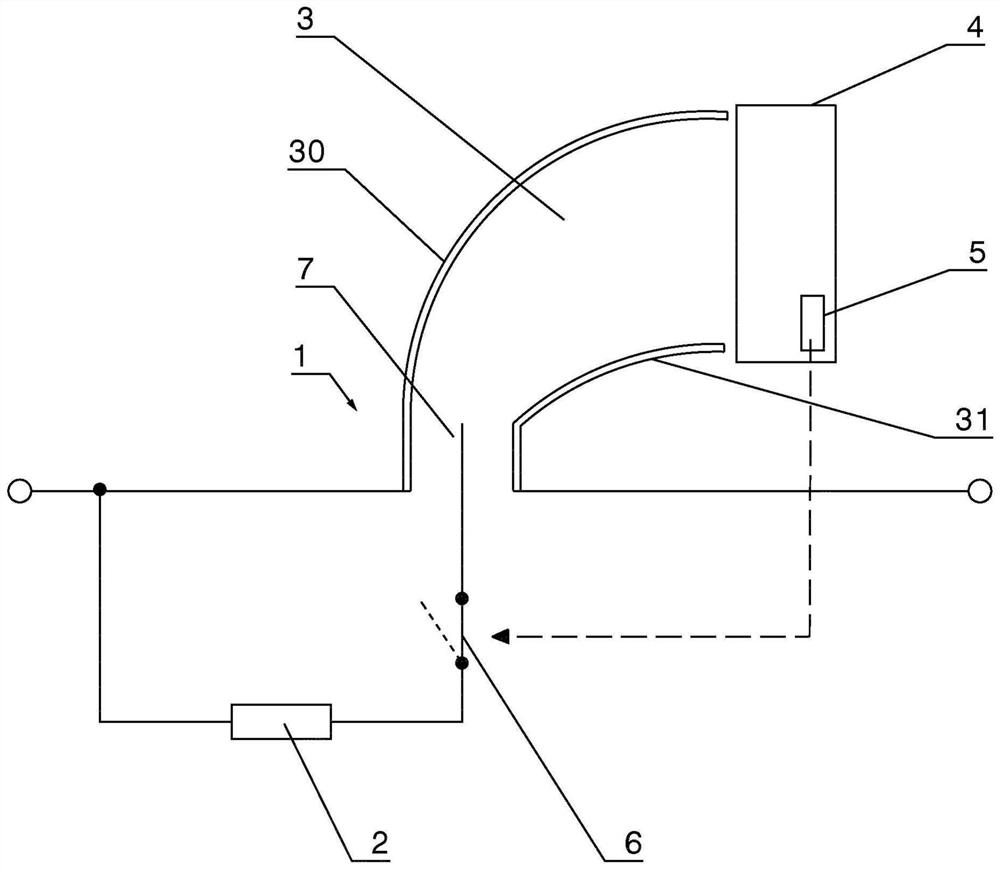

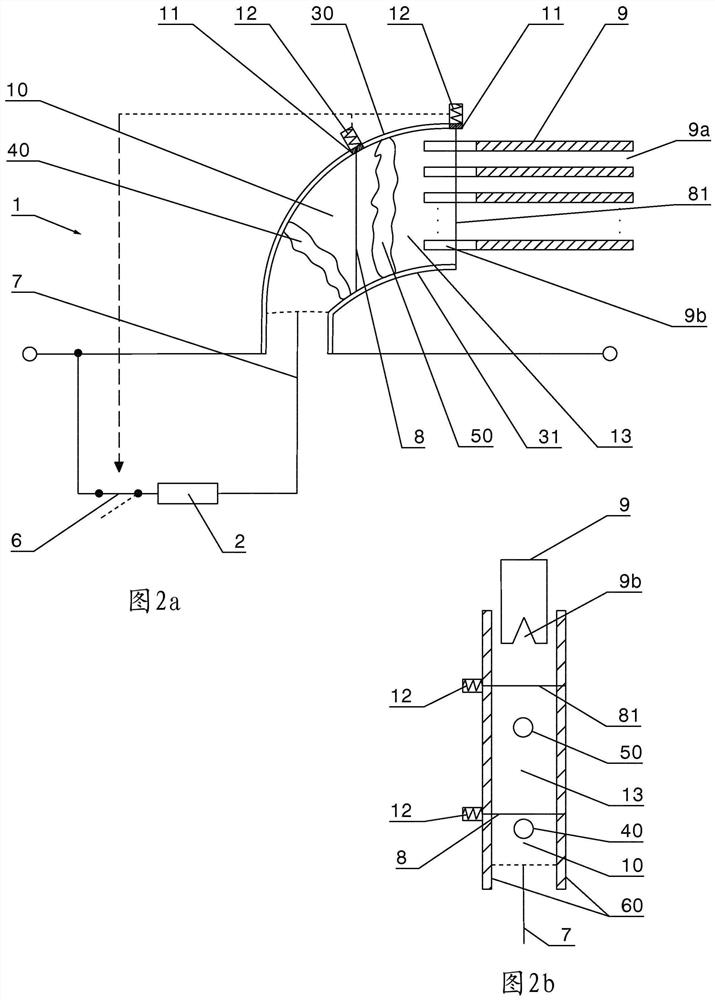

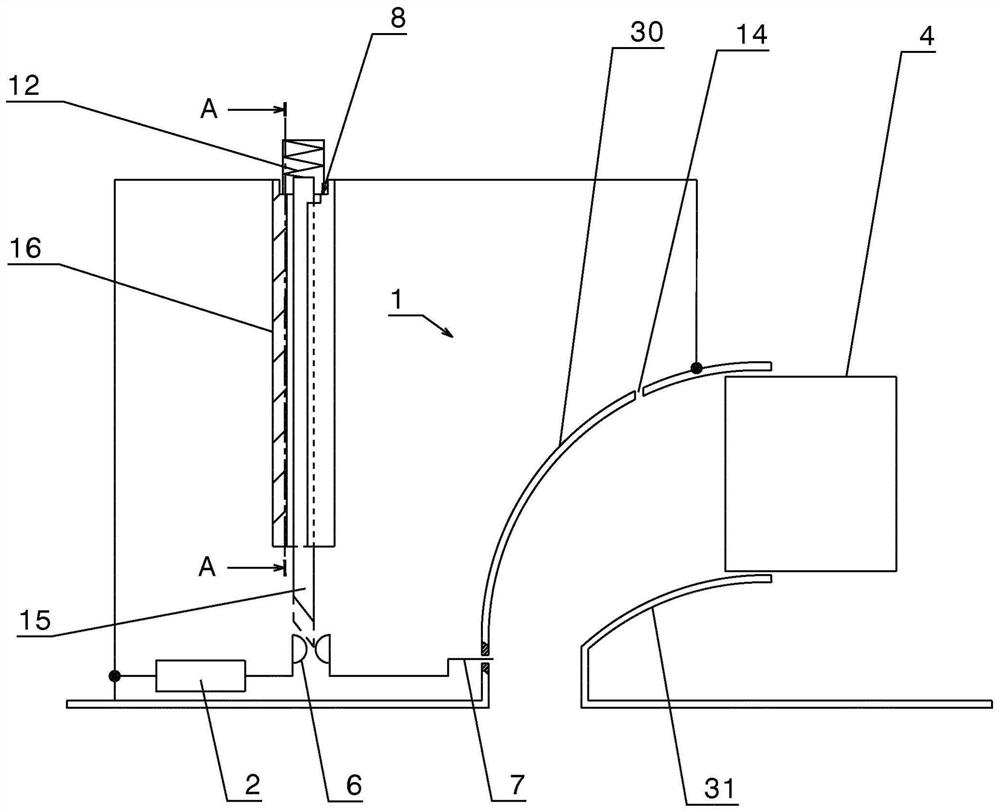

[0047] according to figure 1 The overvoltage protection device is based on a spark gap 1 with a trigger circuit 2. The spark gap has two stylized arc-shaped corner electrodes 30 , 31 which form the arc-running region 3 . Ignition or auxiliary electrodes 7 are located in the foot region of corner electrodes 30 , 31 and are connected to trigger circuit 2 .

[0048] The disconnecting element 6 , which is configured, for example, as a switch, can interrupt the connection between the ignition electrode or the auxiliary electrode 7 and the triggering circuit 2 .

[0049] The arc travel area 3 is followed by a deionization or arc chute 4 which houses a plurality of deionization or arc chute plates (not shown).

[0050] The evaluation unit 5 is located in the region of the deion chamber 4 .

[0051] The evaluation unit 5 is formed by a fuse in the form of a wire. When the fuse is overloaded, the disconnect element or switch 6 is activated (schematically indicated by an arrow) to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com