Reinforcing bar binding machine

A strapping machine and steel bar technology, which is applied to the parts, structural elements, building components, etc. of the strapping machine, can solve the problems of high height, complex structure, corrosion of steel bars, etc., and achieve simple structure, formation of smooth circles, restraint of steel bars The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Next, embodiments of the present invention will be described with reference to the drawings.

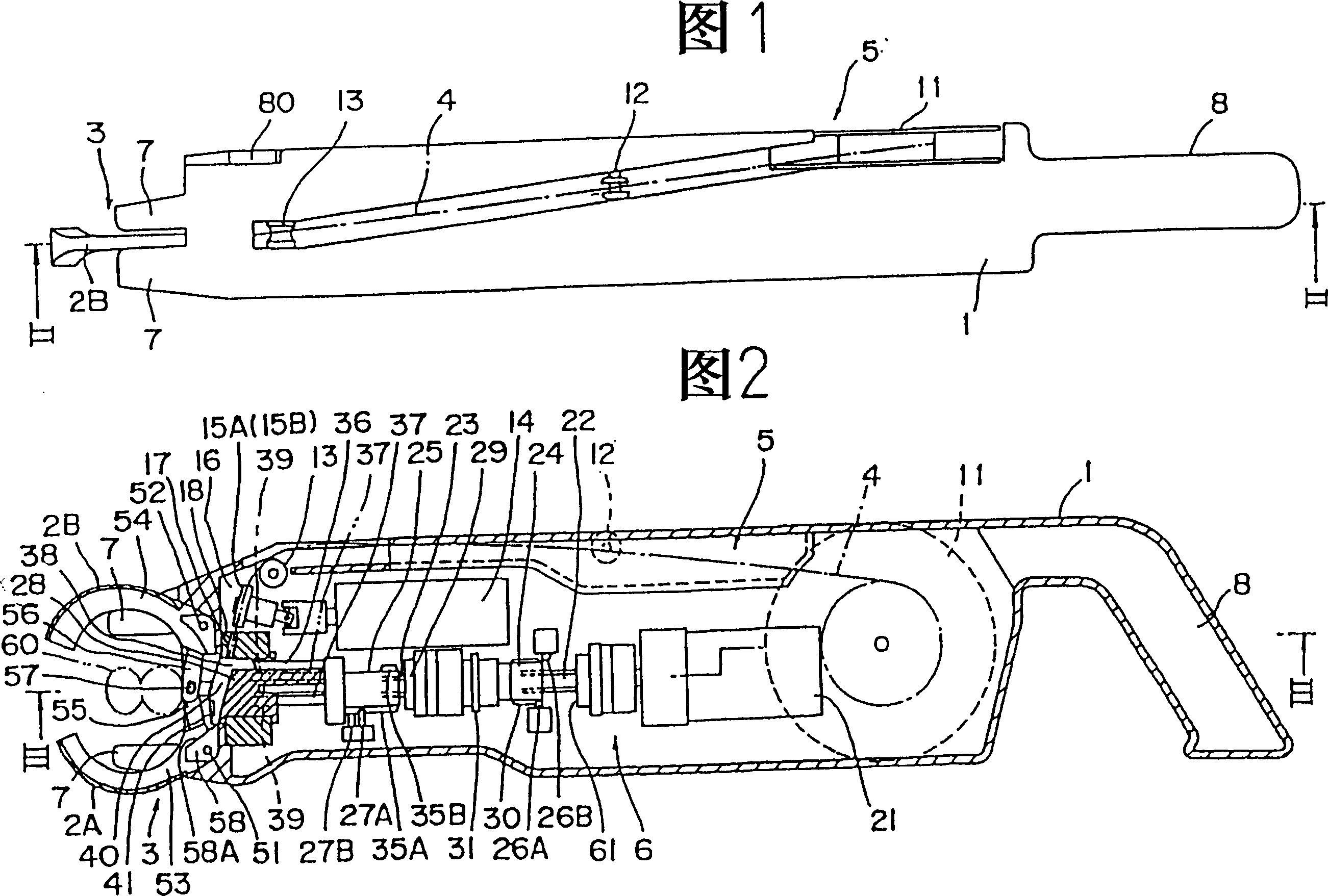

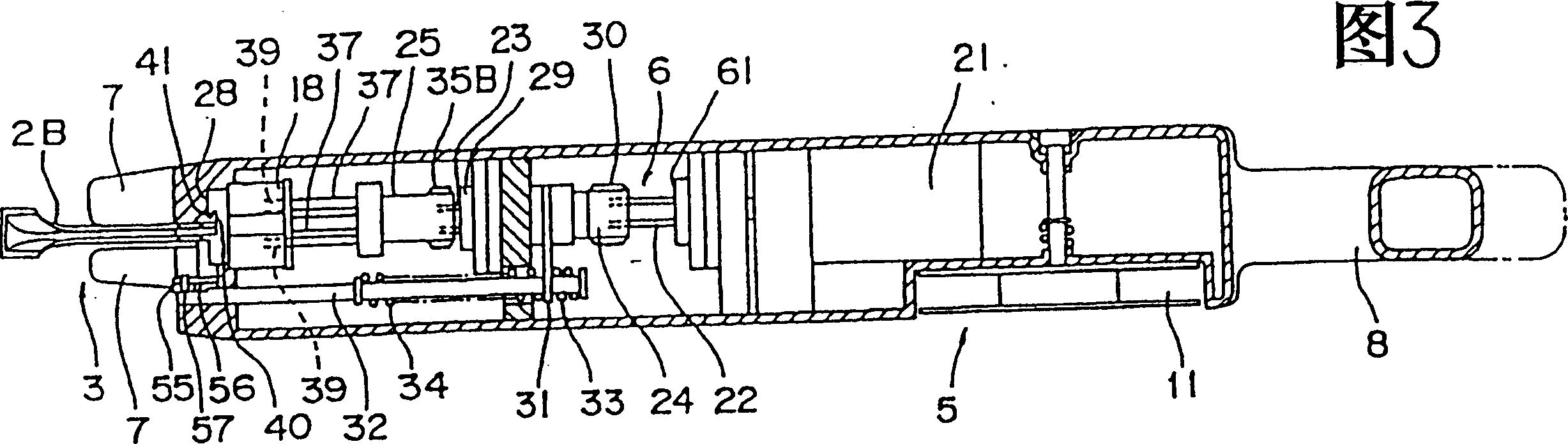

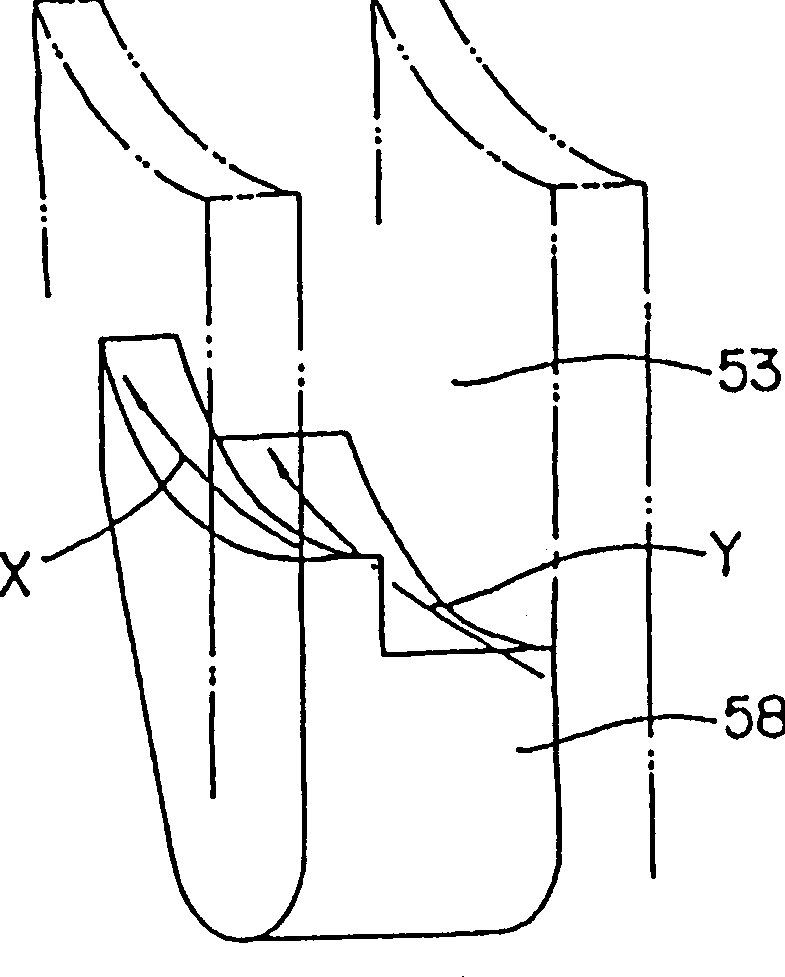

[0066] Fig. 1-3 has shown about the steel bar binding machine of the present invention, and it is provided with the ring forming part 3 of a pair of curved member 2A, 2B that has groove that can be arranged on this main body 1 head can open and close. composition.

[0067] The main body 1 is provided with a wire supply unit 5 that feeds the wire 4 to the loop forming unit 3 and a drive mechanism 6 that cuts the wire 4, opens and closes the bending member, twists the traveler, etc., as will be described in detail below. In addition, at the front of the main body 1, that is, at the left end in FIG. . The extension part 7, in addition to the action of making the steel bar crossing part in the twisted center position, also plays a role in preventing the bending members 2A, 2B from colliding with the steel bar or other things and being damaged.

[0068] The steel wire supply uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com