Sodium flame method detection system

A detection system and detection device technology, applied in the field of nuclear detection, can solve problems such as large radioactive technical waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

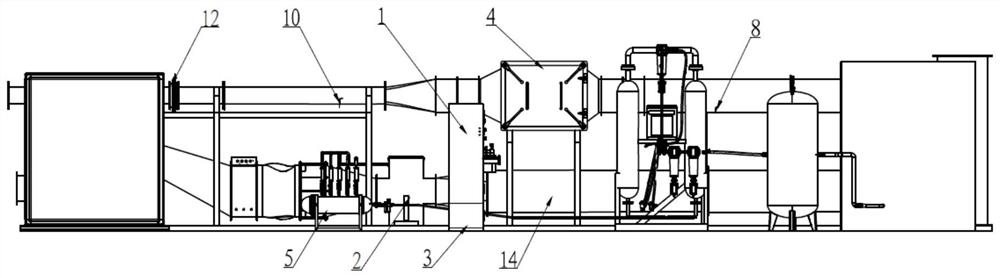

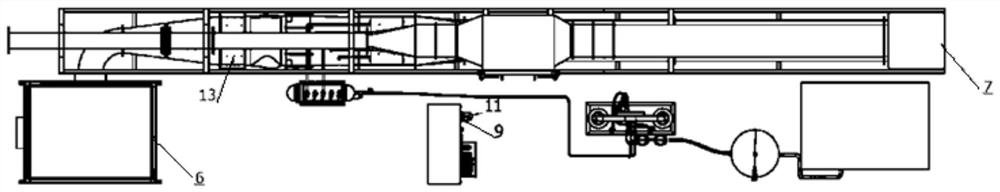

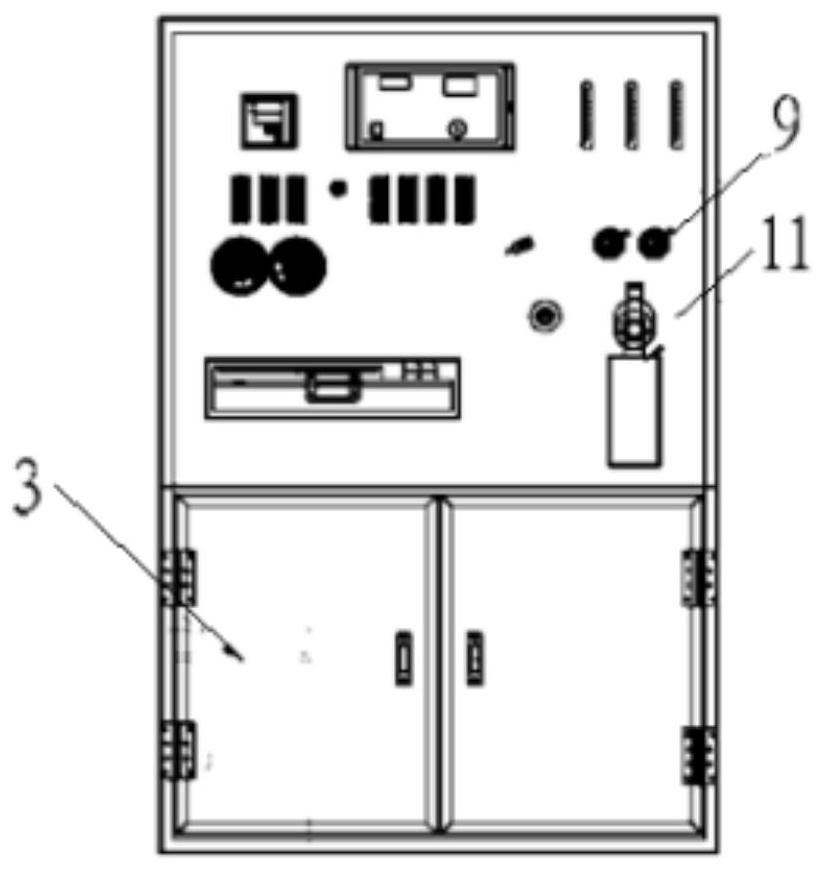

[0025] The mobile air filter sodium flame test system is designed in accordance with the requirements of "High Efficiency Air Filter Performance Test Method Efficiency and Resistance" (GB / T 6165), and is used to test the efficiency and resistance of air filters. The system includes a detection platform, a fogging device (spray box), a hydrogen generator, an aerosol and a detection device, an air duct system, and a compressed air supply system. All the above equipment components are installed in the 40GP container, which makes the testing equipment intensive, miniaturized and easy to transfer, and can realize the testing of air filters in multiple nuclear power plants. A temperature-controlled exhaust system is installed in the container to keep the operating environment in a normal temperature and humidity environment to ensure the accuracy of the detection.

[0026] Principle of testing equipment

[0027] The mobile air filter sodium flame detection system is mainly composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com