Experimental gas generating device

A gas generating device, a technology used in experiments, applied in the directions of mixers, dissolvers, mixers, etc. with rotary stirring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific examples.

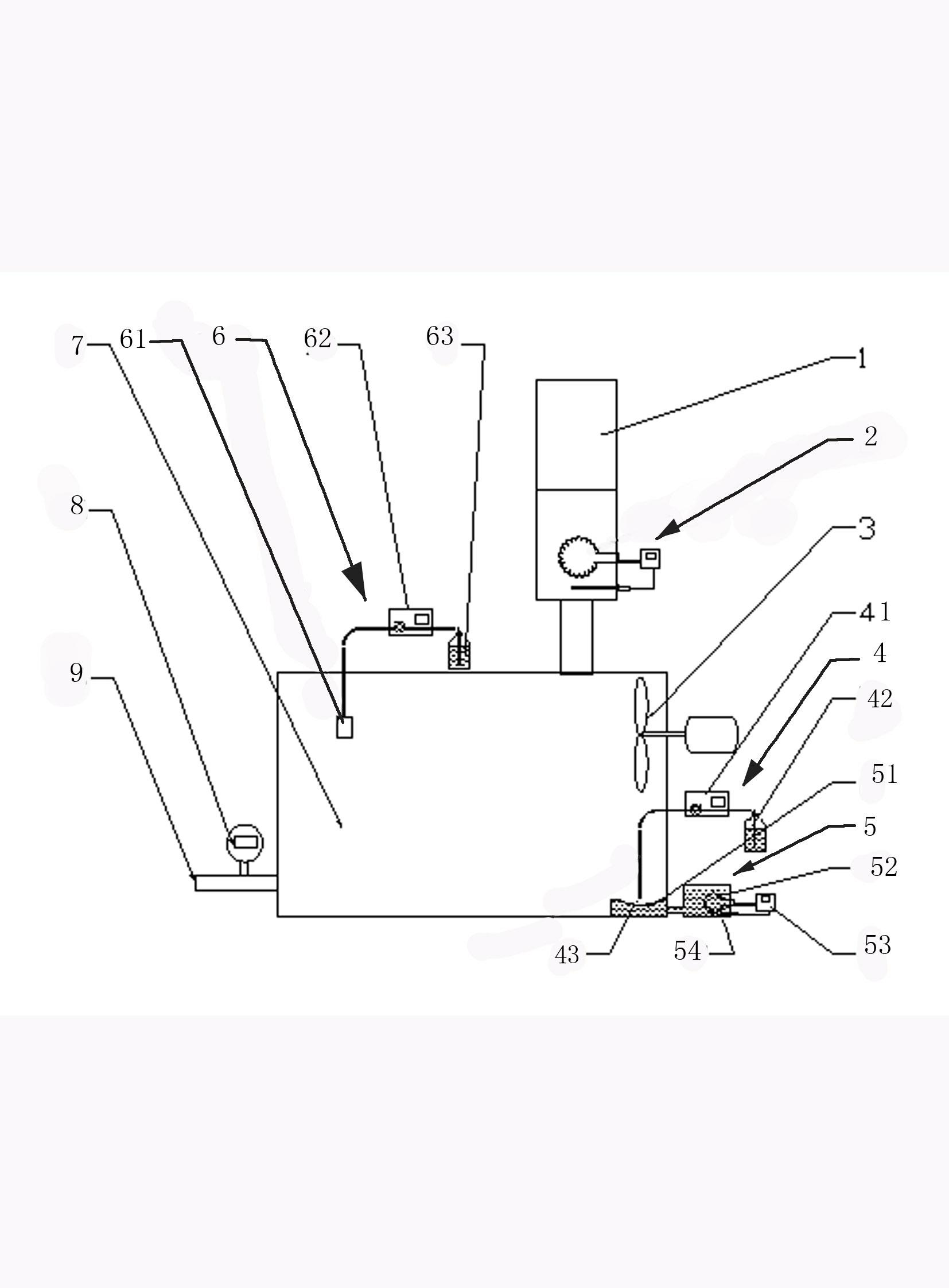

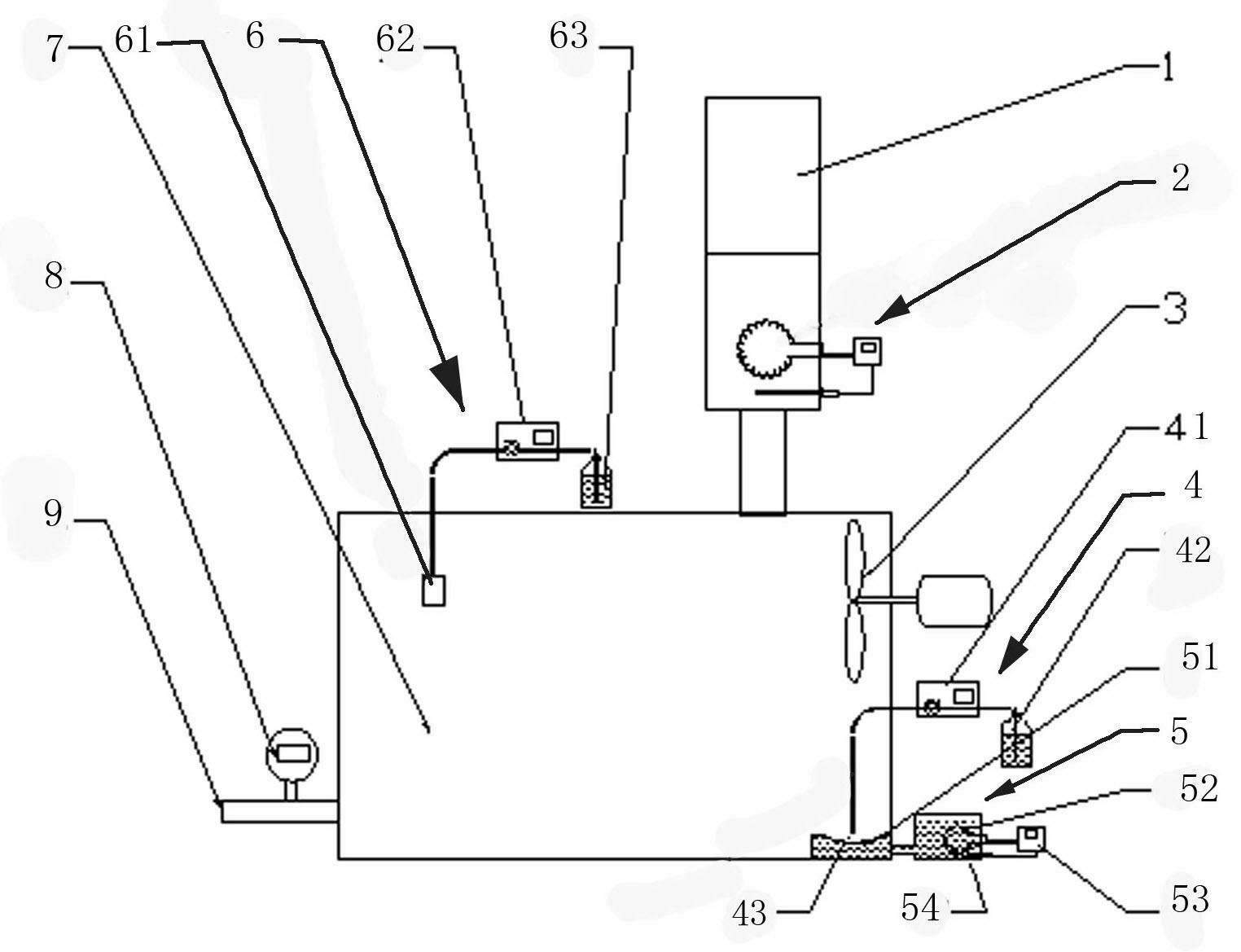

[0016] An experimental gas generating device, such as figure 1 As shown, a buffer tank 7 is included, and the buffer tank 7 is provided with an air inlet, an air outlet 9, a medicament input port and a water input port, and the air inlet is sequentially provided with an air intake purification device 1 and a water inlet along the airflow direction. Air intake heating device 2, an air flow meter 8 is installed at the air outlet 9 of the buffer tank 7, the drug input port is connected to the drug input device 4 that quantitatively inputs the drug in the buffer tank 7, and the water input port is connected with The water input device 6 quantitatively sprays water to the buffer tank 7, and the buffer tank 7 is equipped with a homogenizing fan 3, a water atomization device 61 and a drug evaporation device 5 for heating and evaporating the input drug.

[0017] The air intake purific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com