A kind of drying equipment with dust filter mechanism

A technology for dust filtration and drying equipment, applied in the fields of dispersed particle filtration, drying of solid materials, lighting and heating equipment, etc. Good dust removal effect, improved dust removal effect, easy dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

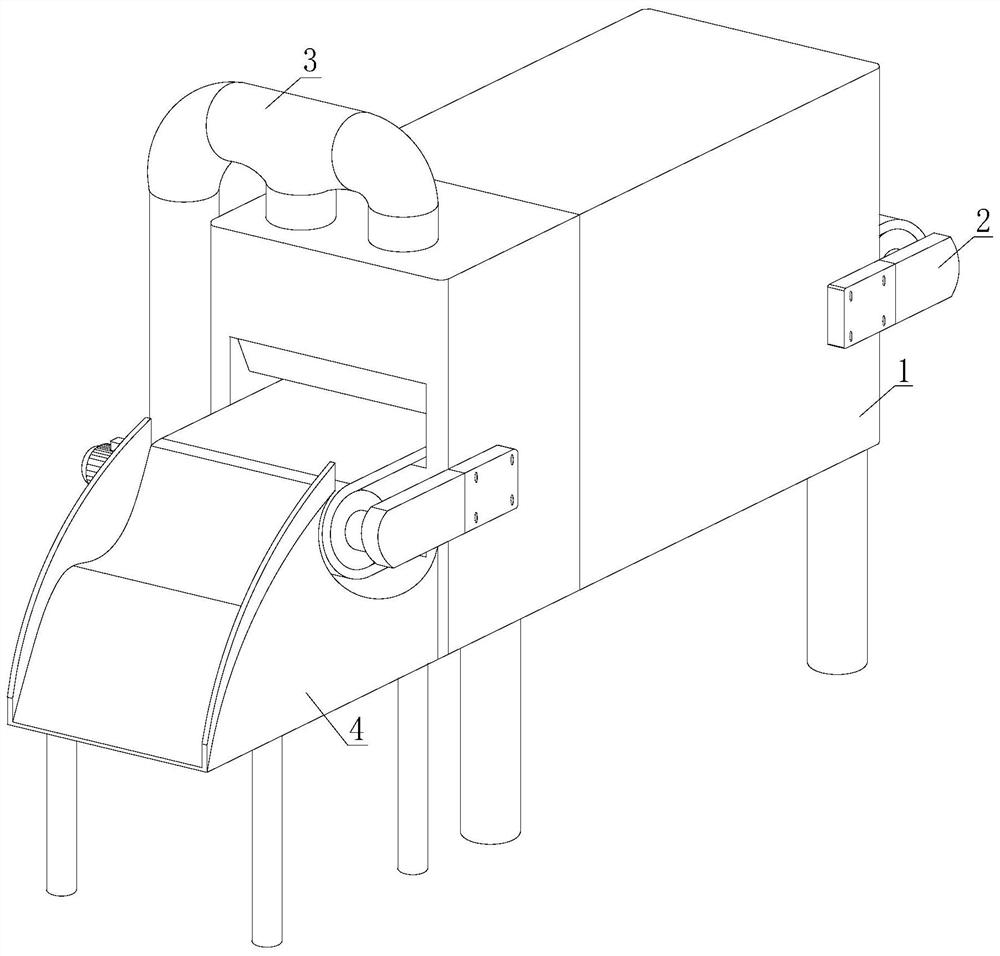

[0033] see figure 1, a drying device with a dust filtering mechanism, including a drying main body 1, a conveying mechanism 2, a primary dust filtering mechanism 3 and a secondary dust filtering mechanism 4, the conveying mechanism 2 runs through the middle of the drying main body 1, and the primary dust filtering mechanism 3 It is arranged at one end of the drying body 1 , and the secondary dust filter mechanism 4 is arranged at the output end of the conveying mechanism 2 .

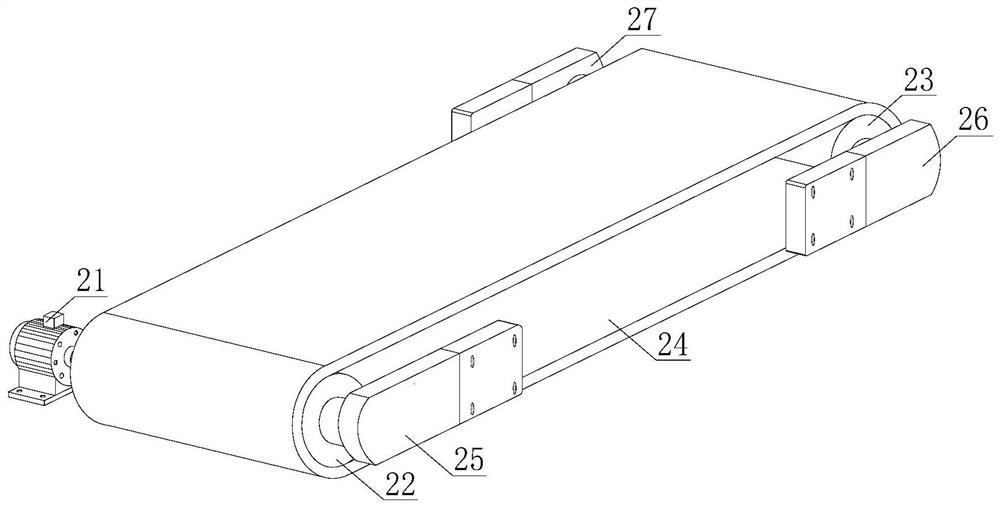

[0034] see figure 2 , a drying device with a dust filter mechanism, the conveying mechanism 2 includes a servo motor 21, a driving shaft 22, a driven shaft 23, a conveyor belt 24, a first mounting frame 25, a second mounting frame 26 and a third mounting frame 27, The lower end of the servo motor 21 is fixedly connected to the drying main body 1, the output end of the servo motor 21 is connected to one end of the drive shaft 22, the other end of the drive shaft 22 is movably connected to one end of the...

Embodiment 2

[0039] see figure 1 , a drying device with a dust filtering mechanism, including a drying main body 1, a conveying mechanism 2, a primary dust filtering mechanism 3 and a secondary dust filtering mechanism 4, the conveying mechanism 2 runs through the middle of the drying main body 1, and the primary dust filtering mechanism 3 It is arranged at one end of the drying body 1 , and the secondary dust filter mechanism 4 is arranged at the output end of the conveying mechanism 2 .

[0040] see figure 2 , a drying device with a dust filter mechanism, the conveying mechanism 2 includes a servo motor 21, a driving shaft 22, a driven shaft 23, a conveyor belt 24, a first mounting frame 25, a second mounting frame 26 and a third mounting frame 27, The lower end of the servo motor 21 is fixedly connected to the drying main body 1, the output end of the servo motor 21 is connected to one end of the drive shaft 22, the other end of the drive shaft 22 is movably connected to one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com