AI-based adaptive variable pressure difference control method for air conditioning variable flow water system

A control method and variable flow technology, applied in heating and ventilation control systems, heating and ventilation safety systems, special data processing applications, etc. Fixed value oscillation and other problems, to achieve the effect of optimizing the water supply temperature, improving the accuracy, and increasing the opening degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in detail below in combination with specific embodiments.

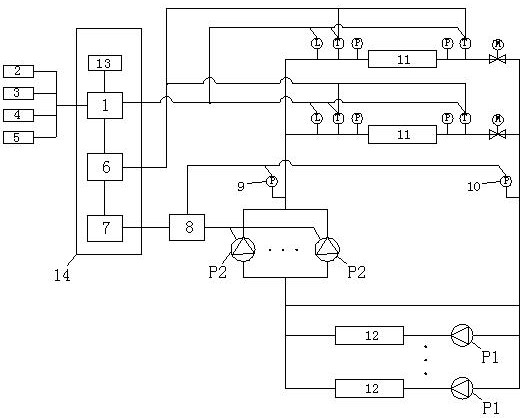

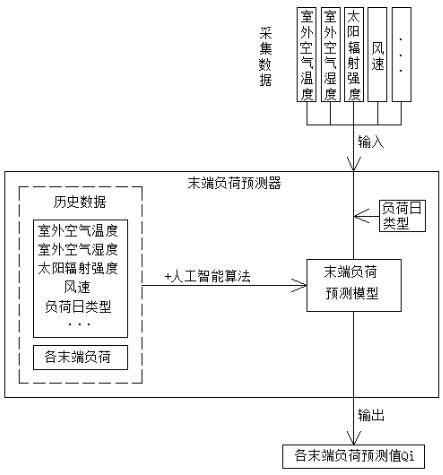

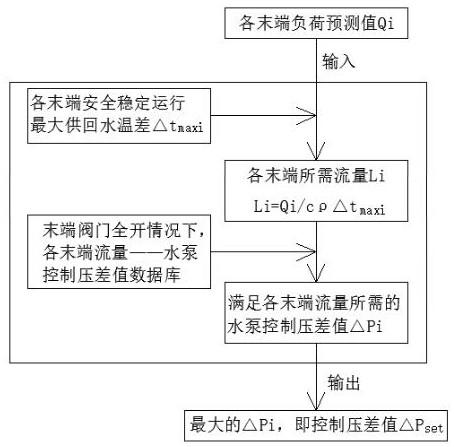

[0059] For specific implementation: see Figure 1-Figure 4 , an AI-based adaptive variable pressure difference control method for an air-conditioning variable flow water system, comprising the following steps: a. Use AI technology to predict the load of each terminal equipment in real time, and obtain the real-time forecasted value of each terminal load; b. According to the historical data and design parameters of terminal equipment operation, the maximum temperature difference between supply and return water for safe and stable operation of each terminal equipment is obtained, and then according to the predicted value of each terminal load, the instantaneous required flow rate of each terminal equipment is calculated; c the instantaneous required flow rate of each terminal equipment The flow rate is substituted into the pre-measured control differential pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com