A dual-redundancy electric steering gear based on worm gear mechanism

A technology of worm gear and electric steering gear, which is applied to electric components, electromechanical devices, transmission devices, etc., can solve the problems of short stroke, instability and difficult control, and achieve the effect of increasing torque, simple structure and avoiding difficult control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the invention, not to limit the invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

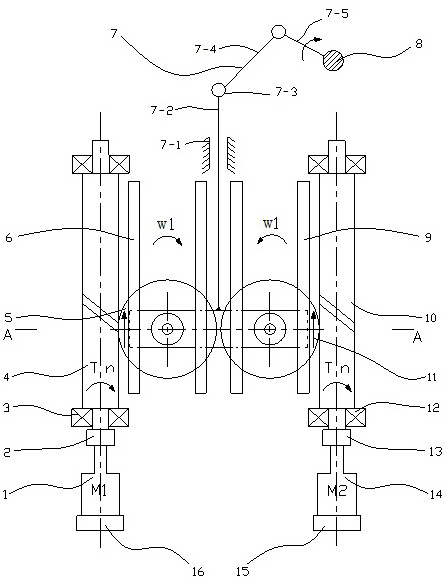

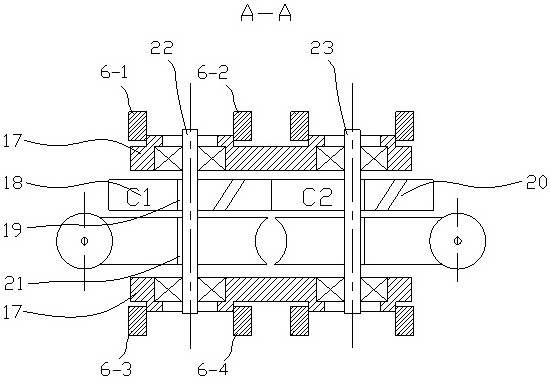

[0020] Such as figure 1 As shown, the embodiment of the present invention provides a dual-redundancy electric steering gear based on a worm gear mechanism. The steering gear is composed of four sets of mechanisms including a first worm gear mechanism, a second worm gear mechanism, a gear set, and a rudder shaft drive unit. .

[0021] The power sources of the first worm gear mechanism and the second worm gear mechanism are tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com