Printable and writable release agent, film material and preparation method of printable and writable release agent

A technology of release agent and writing film, applied in the direction of coating, etc., can solve the problems of not having other properties, and achieve the effect of solving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

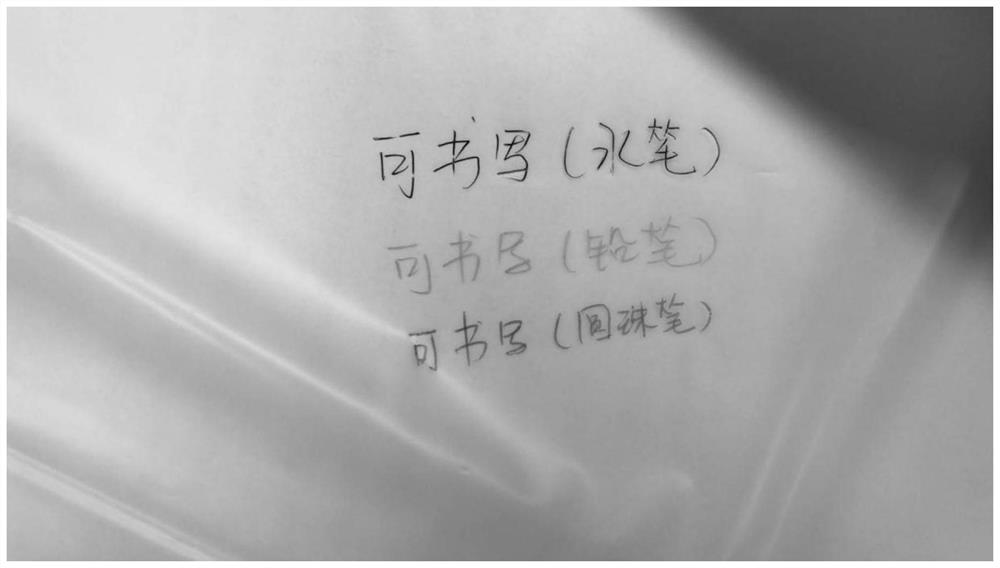

Image

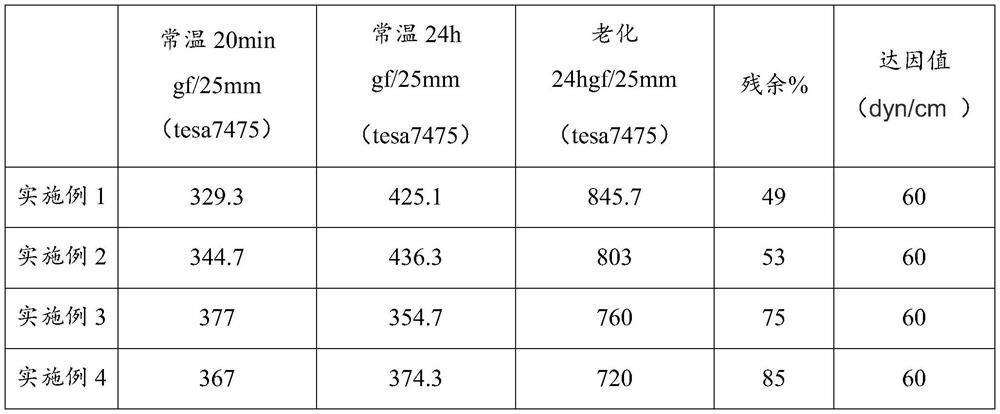

Examples

Embodiment 1

[0027] This embodiment provides a printable and writable film material, the preparation method of which is as follows:

[0028] 1. Prepare the coating solution: dissolve the non-silicon release agent poly(N-octadecyl vinyl carbamate) in a mixed solvent composed of 80% toluene and 20% ethyl acetate, heat up to 50-60°C and Insulation; then add 5wt% additives, wherein additives include glycidyl acrylate 35%, sodium laurylalanine 50%, fluorine-containing prepolymer perfluorobutyl ethyl acrylate 14%, 2, 0.7% of 6-di-tert-butyl-4-methylphenol, 0.3% of 2-amino-3-methylphenol. After uniformly mixing each component, a coating liquid is obtained, and the solid content of the coating liquid is adjusted to 0.5%.

[0029] 2. Coating: The prepared coating solution is coated on the PET substrate by using the micro-recessed coating process, and the coating temperature is controlled at 50-60°C, and the coating amount is 0.08g / cm 2 ; After the coating is completed, it is sent to a heat preser...

Embodiment 2

[0031] This embodiment provides a printable and writable film material, the preparation method of which is as follows:

[0032] 1. Prepare the coating solution: dissolve the non-silicon release agent poly(N-octadecyl vinyl carbamate) in a mixed solvent composed of 80% toluene and 20% ethyl acetate, heat up to 50-60°C and Insulation; then add 5% additives, wherein the additives include 35% glycidyl acrylate, 50% sodium laurylalanine, 14% fluorine-containing prepolymer perfluorobutyl ethyl acrylate, 2, 0.7% of 6-di-tert-butyl-4-methylphenol and 0.3% of 2-amino-3-methylphenol were uniformly mixed to obtain a coating liquid, and the solid content of the coating liquid was adjusted to 0.7%.

[0033] 2. Coating: The prepared coating solution is coated on the PET substrate by using the micro-recessed coating process, the coating temperature is controlled at 50-60°C, and the coating amount is 0.1g / cm 2 ; After the coating is completed, it is sent to a heat preservation room at 50°C f...

Embodiment 3

[0035] This embodiment provides a printable and writable film material, the preparation method of which is as follows:

[0036] 1. Prepare the coating solution: dissolve the non-silicon release agent poly(N-octadecyl vinyl carbamate) in a mixed solvent composed of 80% toluene and 20% ethyl acetate, heat up to 50-60°C and Insulation; then add 10% additives, wherein the additives include 40% glycidyl acrylate, 45% sodium laurylalanine, 14% fluorine-containing prepolymer perfluorooctyl ethyl acrylate, 2, 0.7% of 6-di-tert-butyl-4-methylphenol and 0.3% of 2-amino-3-methylphenol were uniformly mixed to obtain a coating liquid, and the solid content of the coating liquid was adjusted to 0.5%.

[0037] 2. Coating: The prepared coating solution is coated on the PET substrate by using the micro-recessed coating process, and the coating temperature is controlled at 50-60°C, and the coating amount is 0.08g / cm 2 ; After the coating is completed, it is sent to a heat preservation room at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com