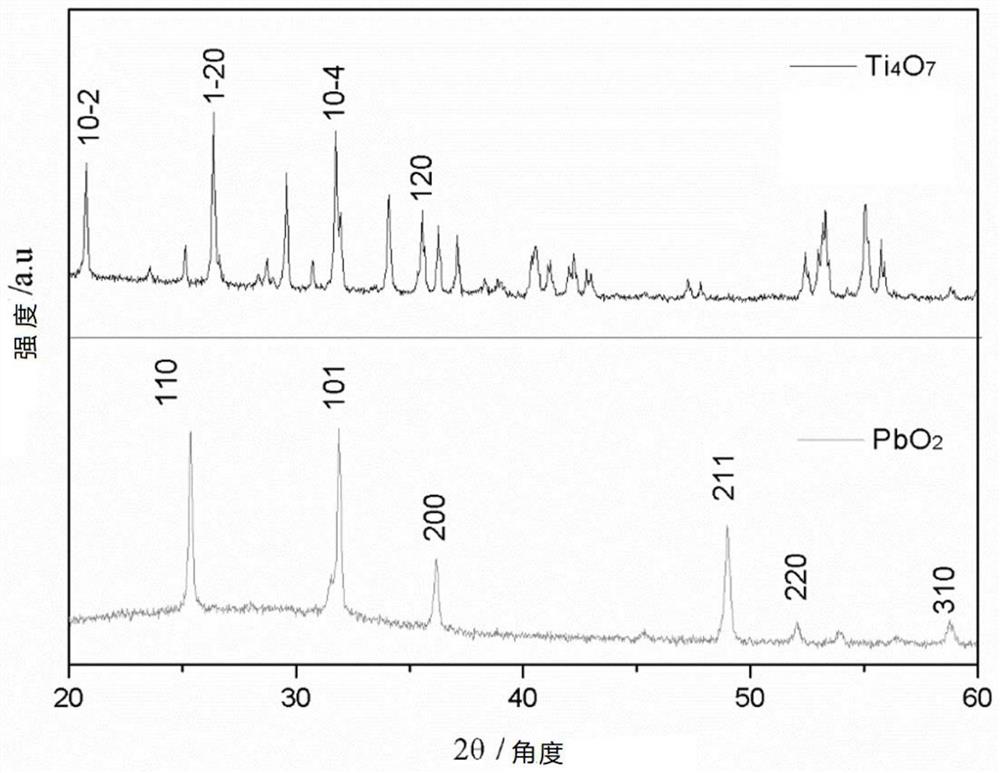

Preparation and application of porous titanium-based titanium black nanotube lead dioxide electrode

A titanium dioxide and lead dioxide technology, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of easy detachment of the catalytic layer, low service life, poor conductivity, etc. , to achieve the effect of improving catalytic performance, enhancing bonding force and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]The preparation method of the porous titanium-based titania nanotube lead dioxide electrode in this embodiment includes the following steps:

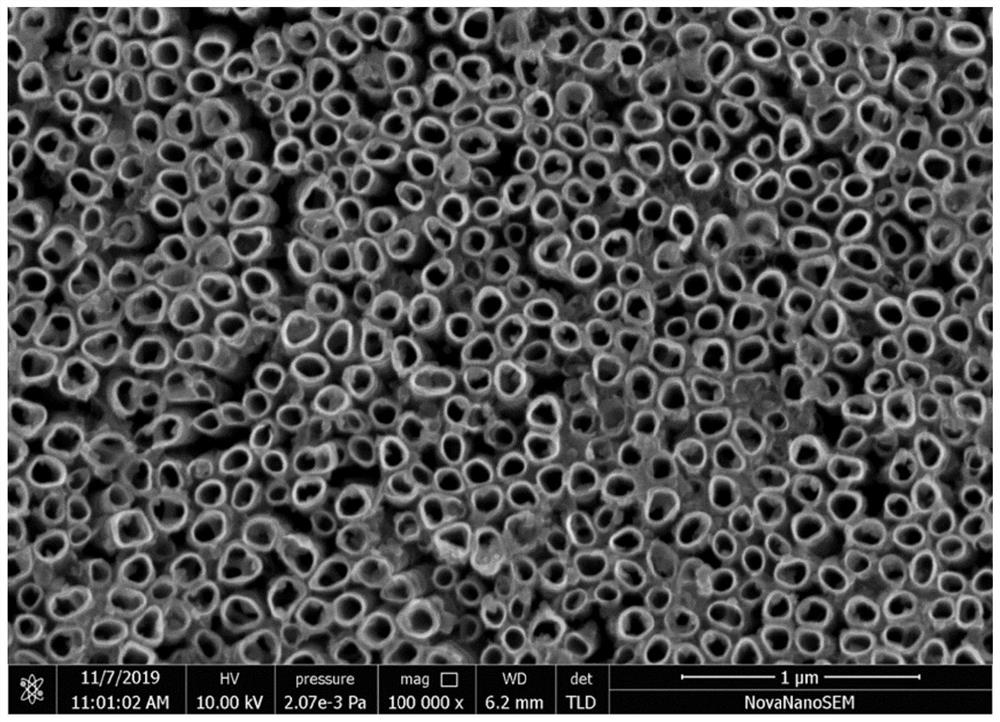

[0048](1) Use the cleaned porous titanium plate as the substrate for anodizing treatment to produce TiO on the surface of the substrate2nanotube;

[0049]Titanium plate cleaning, put the titanium electrode sheet with a filtration accuracy of 20μm into a 200mL beaker, and pour the isopropanol solution to submerge the titanium electrode sheet, and then ultrasonically clean for 15 minutes. After ultrasonic cleaning, rinse the titanium with ultrapure water twice The electrode pads are placed in an oven at 100°C and dried for 15 minutes. Finally, the above steps are repeated with ethanol and NaOH solution;

[0050]Titanium dioxide nanotubes are prepared by preparing a mixed solution with a mass ratio of ethylene glycol and ultrapure water of 4, then adding 0.5% ammonium fluoride, and then using porous titanium as the anode, stainless steel as the cat...

Embodiment 2

[0060]The preparation method of the porous titanium-based titania nanotube lead dioxide electrode in this embodiment includes the following steps:

[0061](1) Use the cleaned porous titanium plate as the substrate for anodizing treatment to produce TiO on the surface of the substrate2nanotube;

[0062]Titanium plate cleaning, put the titanium electrode sheet with a filtration accuracy of 20μm into a 200mL beaker, and pour the isopropanol solution to submerge the titanium electrode sheet, and then ultrasonically clean for 15 minutes. After ultrasonic cleaning, rinse the titanium with ultrapure water twice The electrode pads are placed in an oven at 100°C and dried for 15 minutes. Finally, the above steps are repeated with ethanol and NaOH solution;

[0063]Titanium dioxide nanotubes were prepared by preparing a mixed solution with a mass ratio of ethylene glycol and ultrapure water of 6, and then adding 0.5% ammonium fluoride, and then using porous titanium as the anode, stainless steel as th...

Embodiment 3

[0102]The preparation method of the porous titanium-based titania nanotube lead dioxide electrode in this embodiment includes the following steps:

[0103](1) Use the cleaned porous titanium plate as the substrate for anodizing treatment to produce TiO on the surface of the substrate2nanotube;

[0104]Titanium plate cleaning, put a 20μm titanium electrode sheet into a 200mL beaker, and pour isopropanol solution to submerge the titanium electrode sheet, then ultrasonically clean for 15 minutes, and then rinse the titanium electrode with ultrapure water twice after ultrasonic cleaning The slices were placed in an oven at 100°C and dried for 15 minutes. Finally, the above steps were repeated with ethanol and NaOH solution;

[0105]Titanium dioxide nanotubes are prepared by preparing a mixed solution with a mass ratio of ethylene glycol and ultrapure water of 5, then adding 0.5% ammonium fluoride, and then using porous titanium as the anode, stainless steel as the cathode, at room temperature, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com