Lifting and horizontal conveying table

A technology for leveling and transporting boards, applied in the direction of lifting frames, lifting devices, etc., can solve the problems of poor stability of ladders, failure to meet the requirements of transportation, and potential safety hazards, so as to reduce labor intensity, improve labor efficiency, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

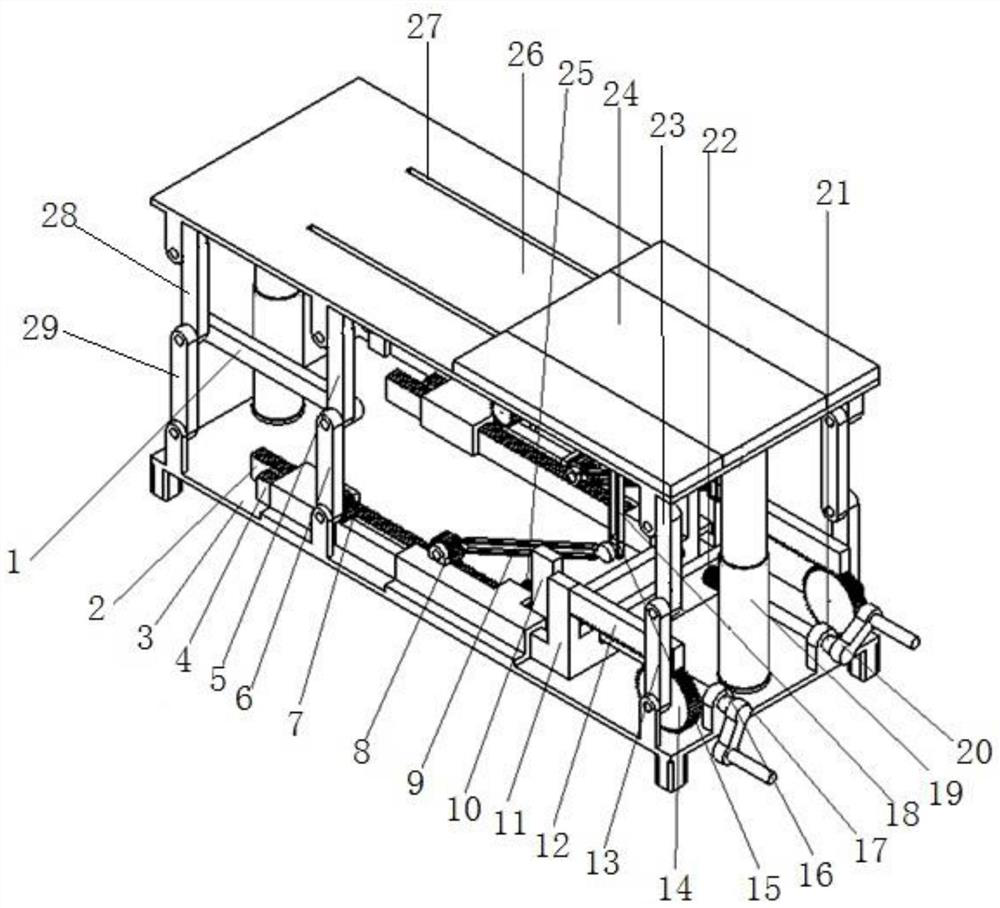

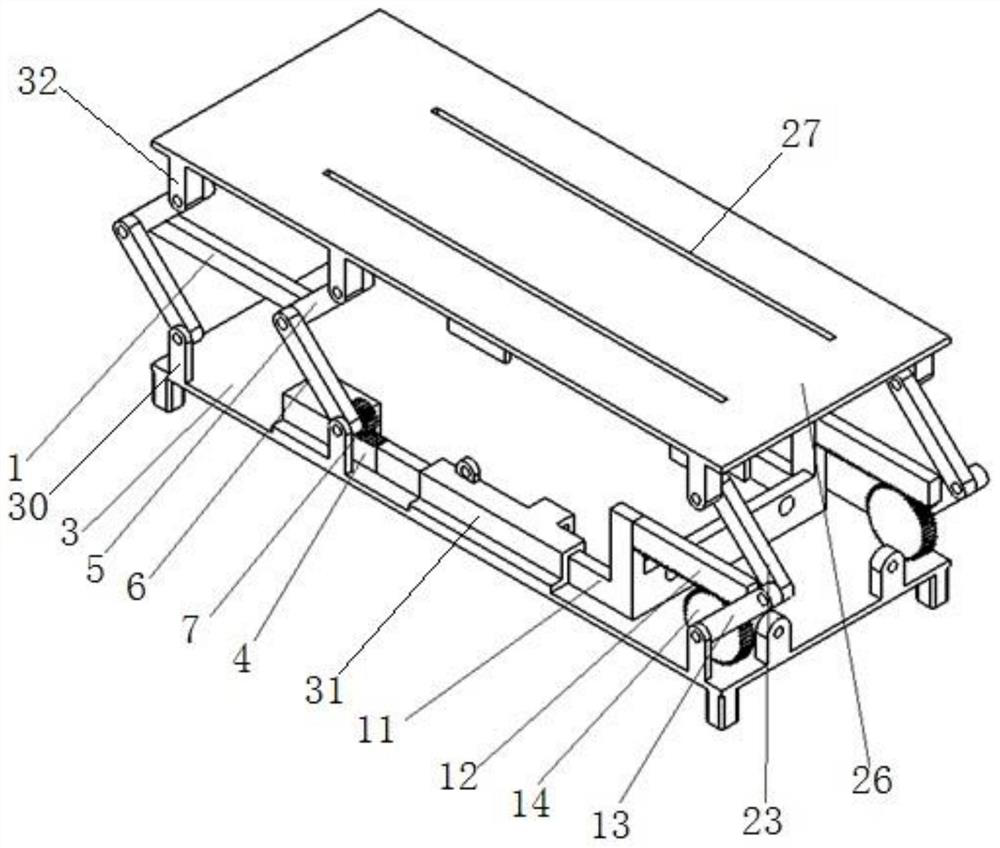

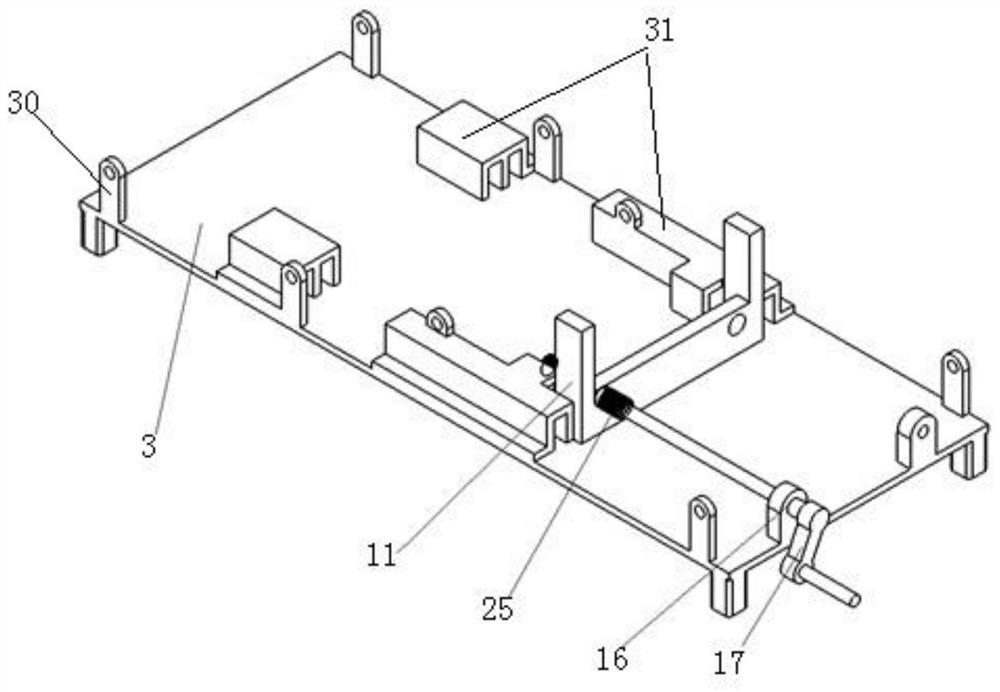

[0028] Such as Figure 1-Figure 5 As shown, a kind of lifting and horizontal conveying platform of the present invention comprises base 3, carrying platform 26, conveying plate 24, lifting mechanism and conveying plate translation mechanism; Lead screw one 22, at least 2 groups of transmission mechanism one and telescoping rod 19 constitute, transmission mechanism one is made up of rack one, gear one, active fork and driven fork; Described sliding seat one 11 is located on the base 3, Rocker 120 drives sliding seat 11 to slide through lead screw 122, rack 1 on sliding seat 11 meshes with gear 1 for transmission; gear 1 is fixedly connected to the bottom of the active swing rod; one end of the active swing rod is hinged to base 3 , the other end of the active swing link is hinged with one end of the driven swing link, and the other end of the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com