Storage device for chemical reagent production

A chemical reagent and storage device technology, applied in the field of chemical reagent turnover equipment, can solve the problems of high labor intensity and low work efficiency of workers, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

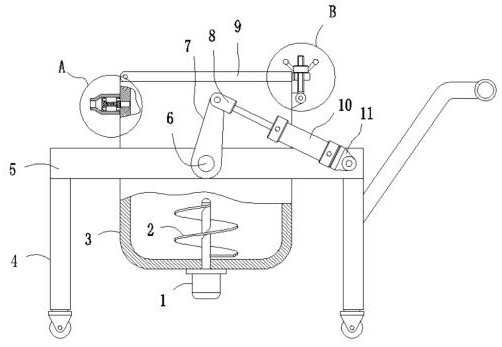

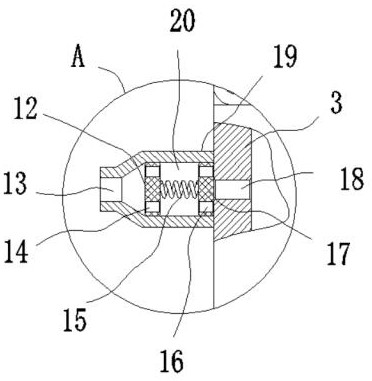

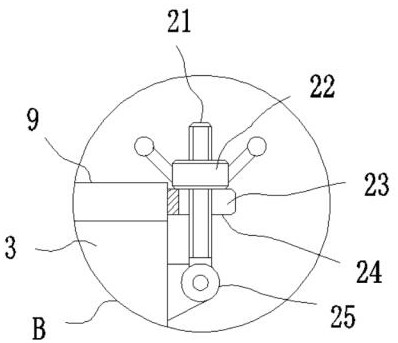

[0022] Such as Figure 1-3 As shown, a storage device for the production of chemical reagents includes a support 5, a plurality of legs 4 are installed at the bottom of the support 5, and moving wheels are provided at the bottom of the legs 4, so that the support 5 can Move on the placement surface, the support 5 is horizontally connected with the storage bin 3 for storing chemical reagents through the installation pivot 6, the top of the storage bin 3 is open and hingedly installed with a bin for closing its interior The cover 9 is detachably installed on the storage bin 3 through the connection structure, and the upper end of the storage bin 3 is provided with a through-hole drain port 18 connected to the inside, and the drain port 18 is installed There is a communication structure for closing its mouth, and the storage bin 3 is driven by the driving structure to rotate in the axial direction with the pivot 6, so that the mouth of the storage bin 3 swings downward.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com