Anti-blocking material milling device for production of artificial leather

An anti-clogging, artificial leather technology, applied in the field of artificial leather, can solve the problems of affecting product quality, low grinding efficiency, blocking the feeding port, etc., to improve the grinding quality, improve the grinding quality, and prevent the effect of cutting too fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

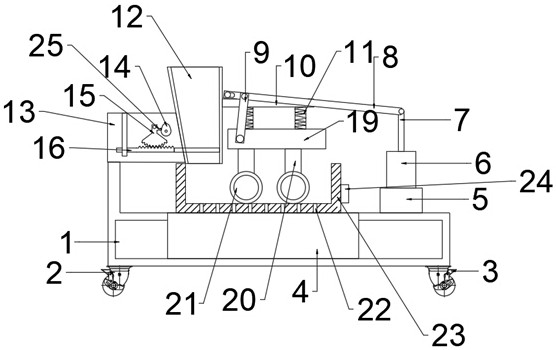

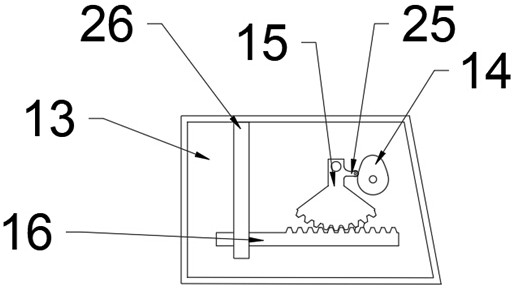

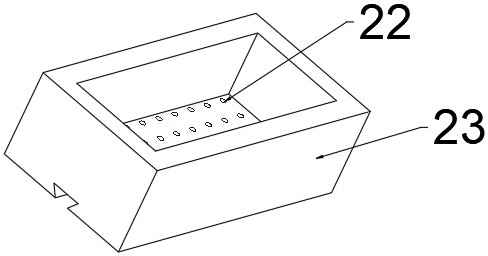

[0030] refer to Figure 1 ~ Figure 3 , an anti-clogging abrasive device for artificial leather production, comprising a box body 1, the top of the box body 1 is connected with a feed port 12, the bottom of the feed port 12 is connected with a grinding box 23, and the inside of the grinding box 23 is set There is an abrasive mechanism, and a power box 13 is connected with bolts above the interior of the box body 1. The interior of the power box 13 is provided with an intermittent feeding mechanism. With the second fixed plate 26, the internal rotation of the power box 13 is connected with a cam 14, and the rear of the cam 14 is provided with a driving mechanism. The complete gear 15 and the incomplete gear 15 are rotatably connected with the box body 1, and the bottom of the incomplete gear 15 is meshed with a spur rod 16, and the spur rod 16 runs through the shell wall of the feed port 12, and the spur rod 16 is slidingly connected with a The second fixed plate 26, the second...

Embodiment 2

[0038] refer to Figure 4 , an anti-clogging abrasive device for artificial leather production. Compared with Embodiment 1, the inner rotation of the feed port 12 is connected with a rotating wheel 17, and the edge bolts of the rotating wheel 17 are connected with several rotating pieces 18. When the raw material When entering the device from the feed port 12, the gravity of the raw material itself is used to rotate the rotating wheel 17 and the rotating piece 18 to perform preliminary intermittent feeding and crushing, which is convenient for subsequent grinding and increases its applicability.

[0039] Working principle: when the raw material enters the device from the feeding port 12, the gravity of the raw material is used to rotate the rotating wheel 17 and the rotating plate 18 to carry out preliminary intermittent cutting and crushing, which is convenient for subsequent grinding and increases its applicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com