Nanofiber filter membrane with anti-bacteria and anti-pollution functions, and preparation method of nanofiber filter membrane

A nanofiber and filtration membrane technology, applied in the field of nanofiber filtration membrane and its preparation, can solve the problems of easy pollution, environmental pollution, complex preparation method, etc., and achieve excellent filtration performance, high graft yield, hydrophilicity Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

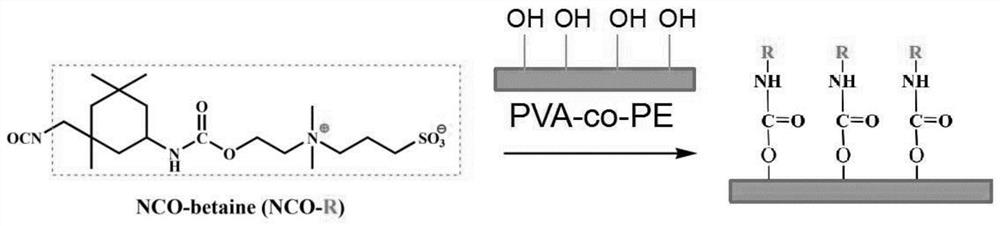

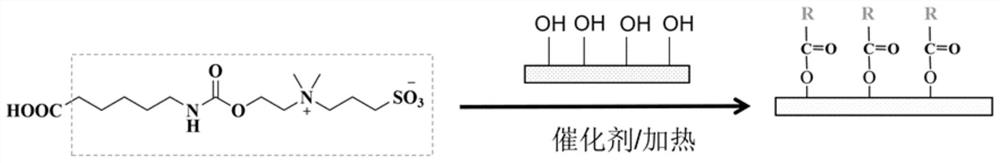

[0041] The invention provides a method for preparing a nanofiber filter membrane for bioseparation with antibacterial and antifouling functions, comprising the following steps:

[0042] S1, PVA-co-PE nanofibers were prepared by melt blending phase separation method;

[0043] S2, disperse the PVA-co-PE nanofibers prepared in step S1 in the mixed solution of isopropanol and water according to the ratio of mass concentration of 5-20%, stir evenly, prepare nanofiber suspension, and seal and store ;

[0044] S3, coating the nanofiber suspension prepared in step S2 on one or both surfaces of the nonwoven support layer, and after drying at room temperature, preparing a composite nanofiber filter layer loaded on the surface of the nonwoven support layer filter membrane;

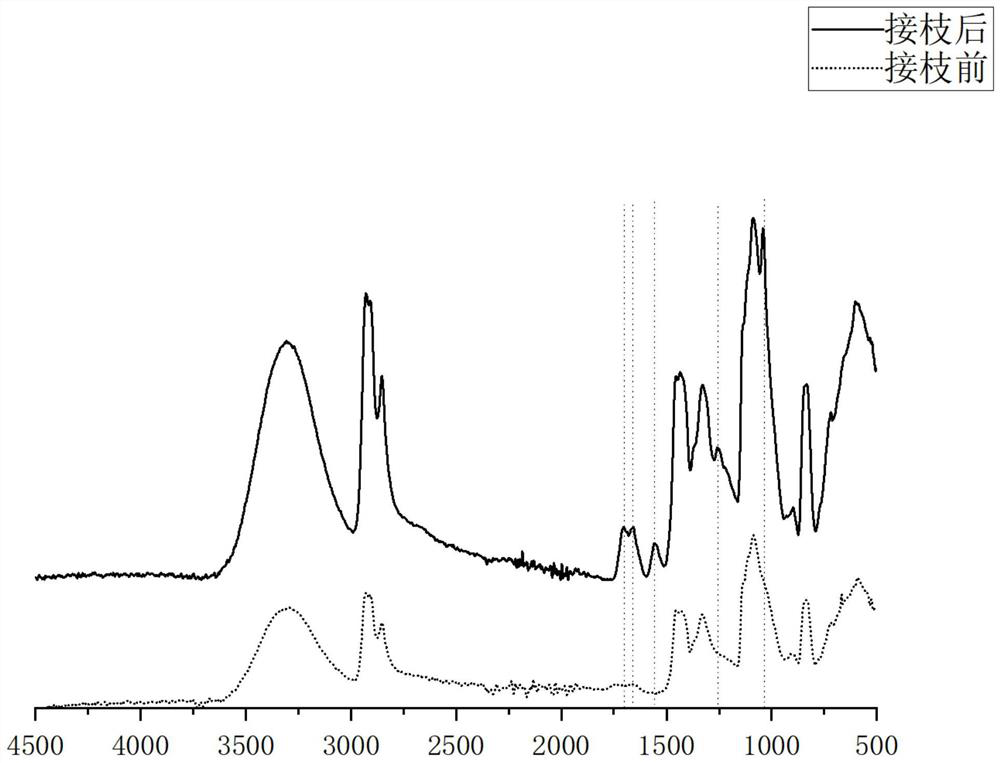

[0045] S4, soak the composite filter membrane prepared in step S3 in the mixed solution containing the amphoteric compound of the grafted monomer, carry out the grafting reaction under certain conditions, then rins...

Embodiment 1

[0078] Embodiment 1 of the present invention provides a method for preparing a nanofiber filter membrane for bioseparation with antibacterial and antifouling functions, comprising the following steps:

[0079] S1, PVA-co-PE nanofibers were prepared by melt blending phase separation method;

[0080] S2, the PVA-co-PE nanofiber prepared in step S1 is dispersed in a mixed solution with a mass ratio of isopropanol and deionized water of 1:1 according to a mass concentration of 10%, and stirred evenly to prepare a nanofiber Fiber suspension, sealed and preserved;

[0081] S3, coating the nanofiber suspension prepared in step S2 on one surface of a nonwoven polypropylene support layer (with an average pore size of 1 to 20 μm), and the coating thickness is 5 μm; after drying at room temperature, the nonwoven fabric is prepared A composite filter membrane with a nanofiber filter layer loaded on the surface of the cloth support layer;

[0082] S4, soaking the composite filter membran...

Embodiment 2-5

[0091] The difference from Example 1 lies in that the temperature and time of the grafting reaction are set differently, and other steps are the same as in Example 1, and will not be repeated here.

[0092] Table 1 is the process parameter setting and performance parameter thereof of embodiment 1-5 and comparative example 1

[0093]

[0094]

[0095] Combined with Table 1 for analysis:

[0096] The influence of temperature and reaction time of grafting reaction on grafting reaction (or modified nanofiber filter layer) is: grafting reaction temperature and time increase, and graft rate increases, and initial water flux can decline to some extent, but cleaning The post-flux recovery increases, and the anti-fouling performance of the nanofibrous membrane is enhanced.

[0097] The composite filter membrane prepared in Comparative Example 1 does not have antibacterial and antibacterial properties, and has poor anti-pollution performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com