Power module shell and power module with same

A technology for a power module and a casing, applied in the field of the power module casing and the power module having the same, can solve the problems of high cost, tearing of the casing wall, large stress, etc. vibratory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below. All other implementations obtained below fall within the protection scope of the present invention.

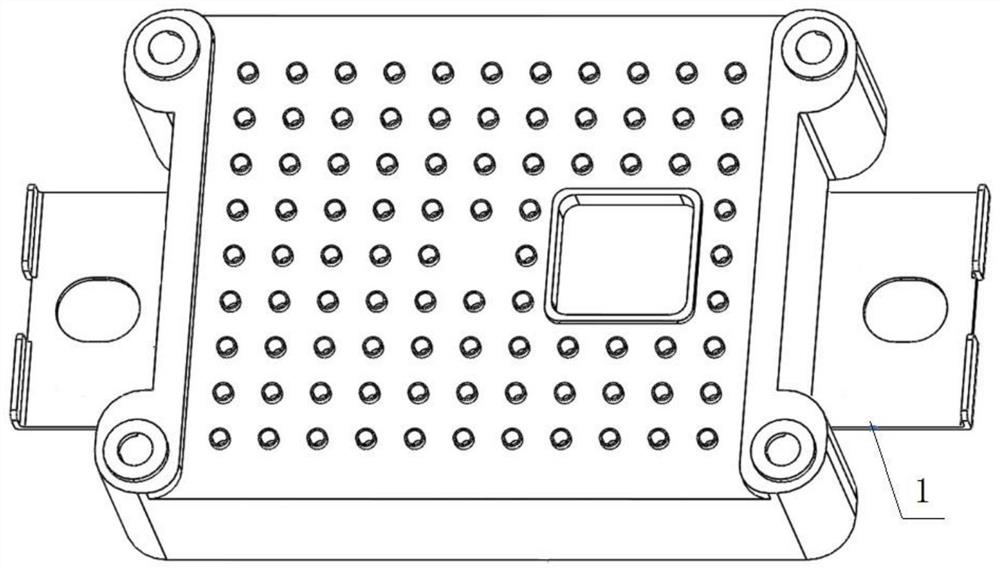

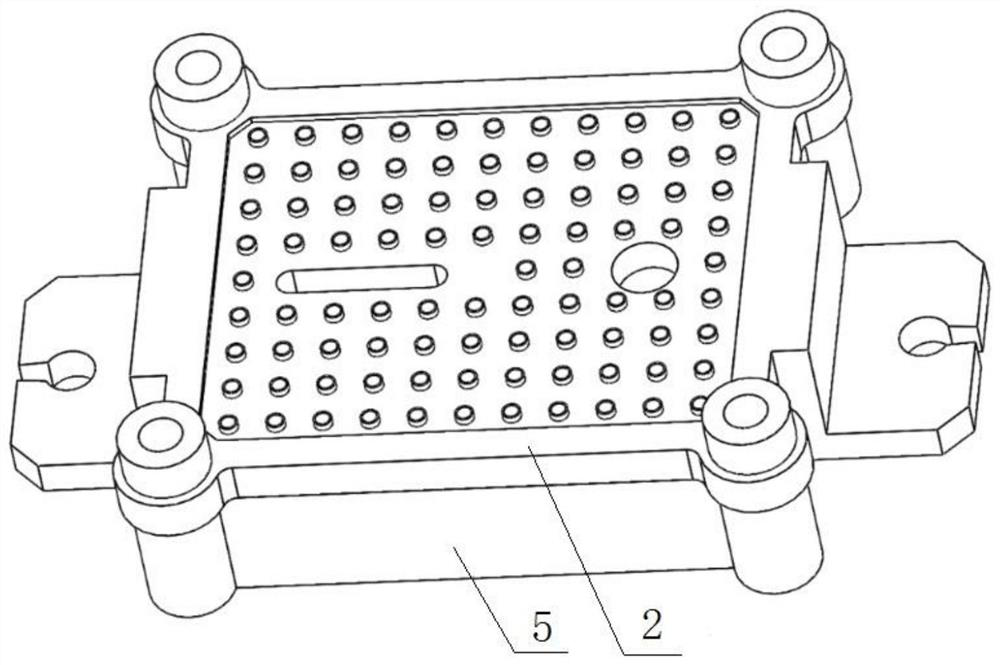

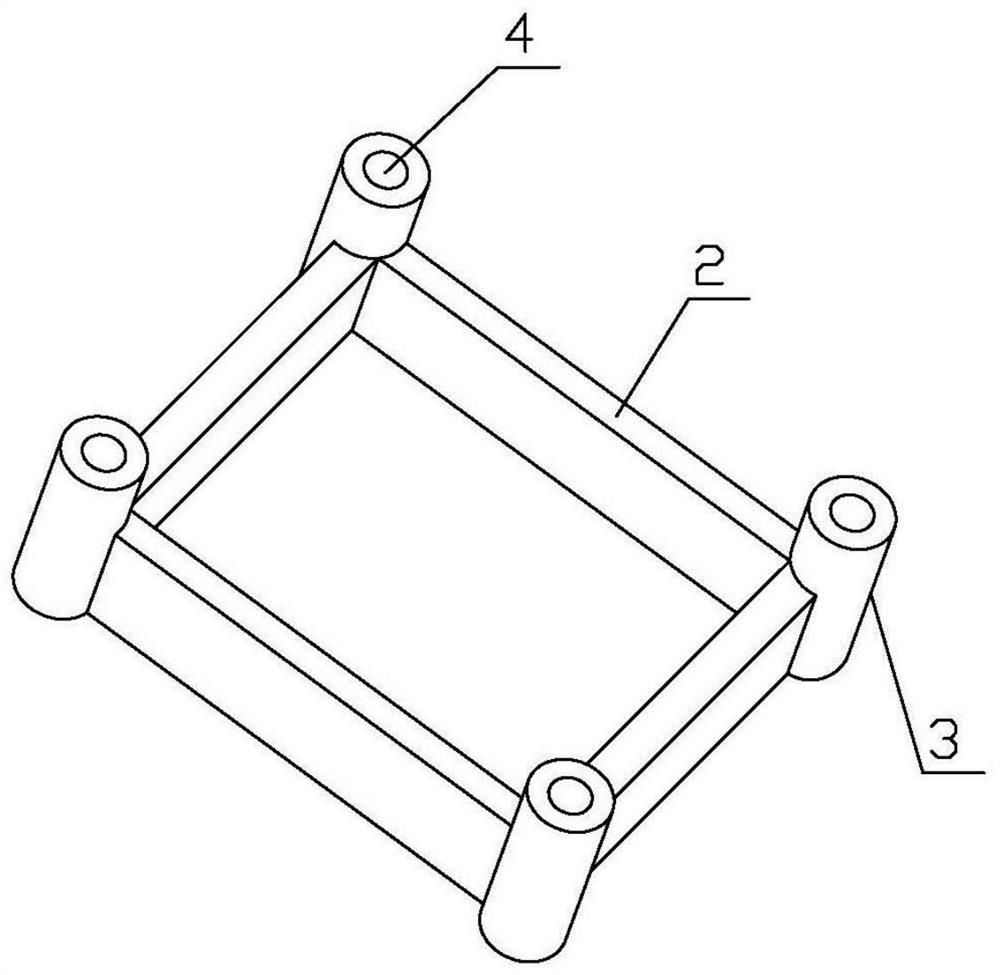

[0037] Such as Figure 2 to Figure 6 As shown, the power module housing 20 provided in this embodiment is assembled from an independently formed housing frame 2 and a housing surface 5. The power module housing 20 is respectively fixed on the PCB board through the housing frame 2, and fixed on the PCB board through the housing surface 5. On the radiator, this can reduce the stress of the power module casing 20, which is beneficial to improve the vibration resistance of the casing; the outer panel 6 and the mounting part 12 are integrally formed by injection molding, which eliminates the need for inlay injection molding of the existing metal mounting ears 1 and plastic frames The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com