Cutter with replaceable blade

A technology of blades and knives, which is applied in the field of knives with replaceable blades, can solve the problems of relatively limited materials for making knives and poor reliability, and achieve the effects of easy alignment and insertion into the knives, easy replacement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

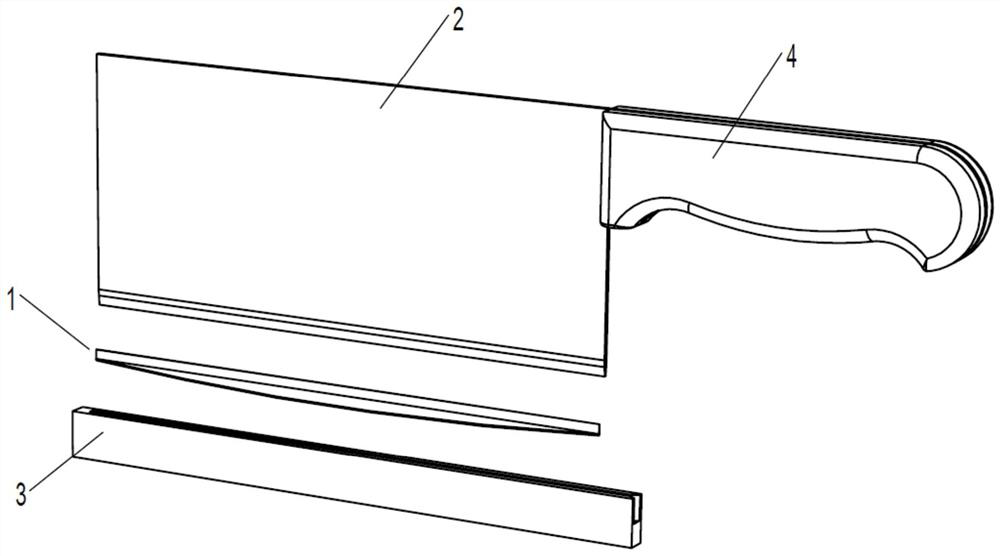

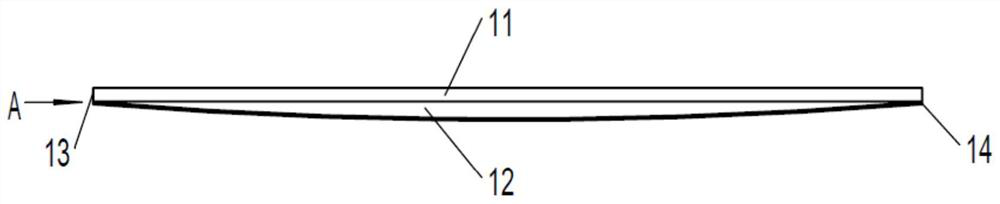

[0055] refer to figure 1 , figure 2 As shown, the blade-replaceable tool includes a blade 1, a blade body 2, a blade replacement device 3 and a handle 4, the handle 4 is bonded to the upper right side of the blade body 2, and the blade 1 has a blade body 11 at the upper end and a blade edge 12 at the lower end , the film header 13 at the left end and the film tail 14 at the right end, the sheet body 11 is flat and can be used for clamping, and the sheet edge 12 has a sharp edge, which is located at the bottom of the blade 1 and provides a cutting function.

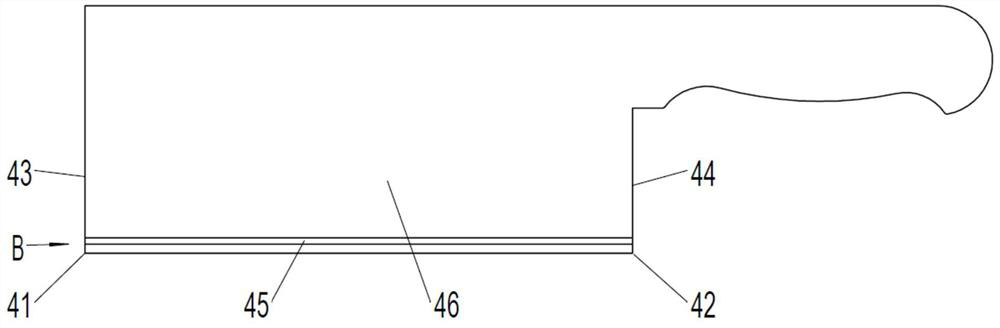

[0056] refer to figure 2 Shown in (a), the cross-section of blade 1 is arrow-shaped, and it has the sheet body side 21 of up-down direction, the blade point 22 of the lowermost part, the blade wing 23 positioned at the middle, the tip wing tip 24 of blade wing 23, The blade tail 25 that connects the wing tip 24 and the side surface 21 of the blade body and is inclined toward the blade tip 22, the angle between the blad...

Embodiment 2

[0063] refer to Figure 7 , Figure 8 As shown, another specific embodiment of a cutter with a replaceable blade disclosed by the present invention, in this embodiment, a transverse protrusion 33 can also be processed on the chip head 13, and the transverse width of the transverse protrusion 33 is not smaller than the chip groove The transverse width of 51; Also can process a longitudinal protrusion 32 on the chip head 13, when sheet body 11 is installed in the sheet groove 51, this longitudinal protrusion 32 is higher than the top surface of sheet groove 51. The transverse protrusion 33 and the longitudinal protrusion 32 block the left end of the sheet groove 51 to prevent the sheet body 11 from moving to the right in the sheet groove 51 .

Embodiment 3

[0065] refer to Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, another specific embodiment of a cutter with a replaceable blade disclosed by the present invention, in this embodiment, a slot plug 91 can also be processed at the right end of the slot 51; Knife feet 61 are pinched and pressed together to form pinch block 92; a slot slit 93 can also be processed on the top surface of the right end of sheet groove 51, and knife foot 61 on the lower side of sheet groove slit 93 surrounds and passes through sheet groove slit 93 The edge line of the up-and-down direction of the end is bent inwardly to form a slit stopper 94; Extension stop 95. Sheet groove plug 91, pinch block 92, slit block 94, extension block 95 can block sheet groove 51 right end openings, for preventing sheet body 11 from shifting to the right in sheet groove 51.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com