Roadbed crushing device for road and bridge construction

A bridge construction and crushing device technology, applied in the direction of filter screen, grille, solid separation, etc., can solve the problems of non-standard stone screening, single function of the crusher, and reduced crushing efficiency, etc., to improve the effect, save manpower, Avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

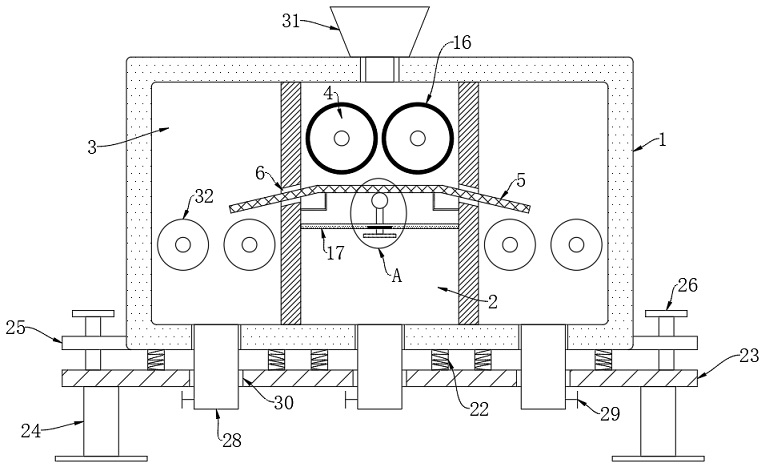

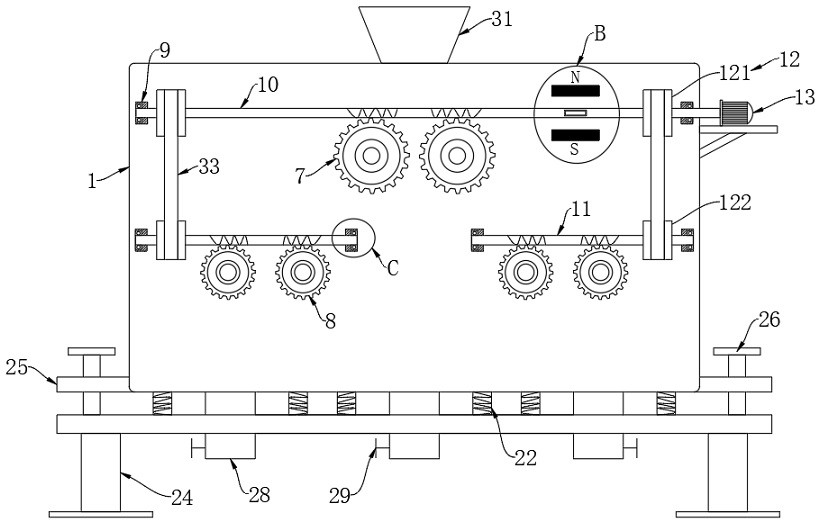

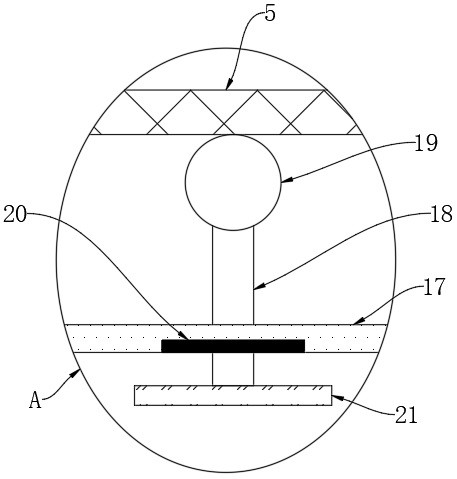

[0032] like Figure 1-5 As shown, a roadbed crushing device for road and bridge construction includes a crushing box 1, a plurality of buffer springs 22 are fixedly connected to the side wall of the lower end of the crushing box 1, and a plurality of buffer springs 22 are jointly fixedly connected with a buffer plate 23, and the buffer plate 23 The lower side wall of the lower end is fixedly connected with a plurality of supporting legs 24, and through the cooperation of the buffer spring 22 and the buffer plate 23, the vibration force generated in the crushing process can be effectively buffered, and the service life of the device can be improved.

[0033] Both side walls of the crushing box 1 are fixedly connected with a support plate 25, and the support plate 25 is slidably connected with a limit rod 26, and the lower end of the limit rod 26 is fixedly connected with the buffer plate 23, and the limit rod 26 provided can The crushing box 1 is limited to prevent the crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com