Freeze-dried preparation production process, freeze-dried preparation and freeze-dried reagent preparation box

A technology for freeze-dried preparations and production processes, which is applied in the directions of drying, drying solid materials, and drying solid materials without heating, which can solve the problems of product supply, poor freeze-dried preparations, and pollution risks during operation, and achieve convenient Transport, reduce the risk of leakage, and save the effect of not afraid of deliquescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] In order to make the technical solutions and beneficial effects of the present invention clearer, the implementation manners of the present invention will be further explained in detail below.

[0095] In order to clearly express and understand the content of the present invention, the present invention is divided into two parts related to the production process of the freeze-dried preparation and the freeze-dried preparation box.

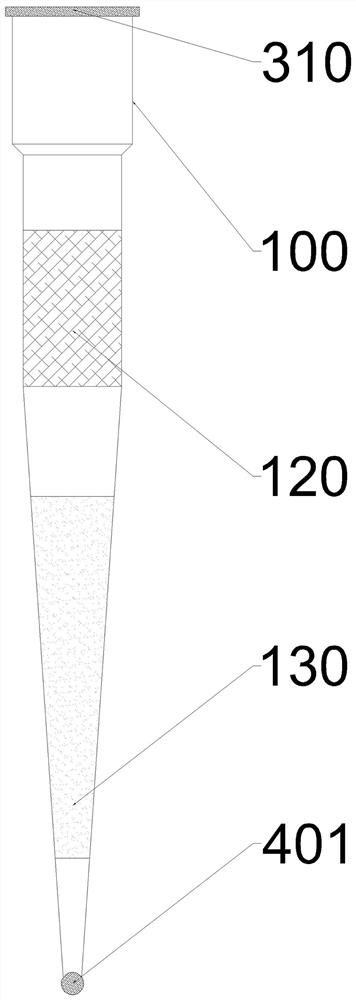

[0096] The first part: about the production process of the freeze-dried preparation and a kind of freeze-dried preparation made.

[0097] The basic principle of freeze-drying is based on the three-state change of water. water (H 2 O) There are three phases, namely solid state, liquid state and gaseous state, and the three phase states can be converted to each other and can coexist.

[0098] Freeze drying uses refrigerant to indirectly reduce the temperature of air containing water vapor, and removes moisture in the air by means of water va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com