Emulsion filter

A filter and emulsion technology, applied in chemical instruments and methods, settling tanks, and controlling the inclination of sedimentation equipment, etc., can solve problems such as tank dumping that cannot be used for emulsion filters, inconvenient cleaning of waste residues, etc., to improve filtration efficiency, It is not easy to break and fall off, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

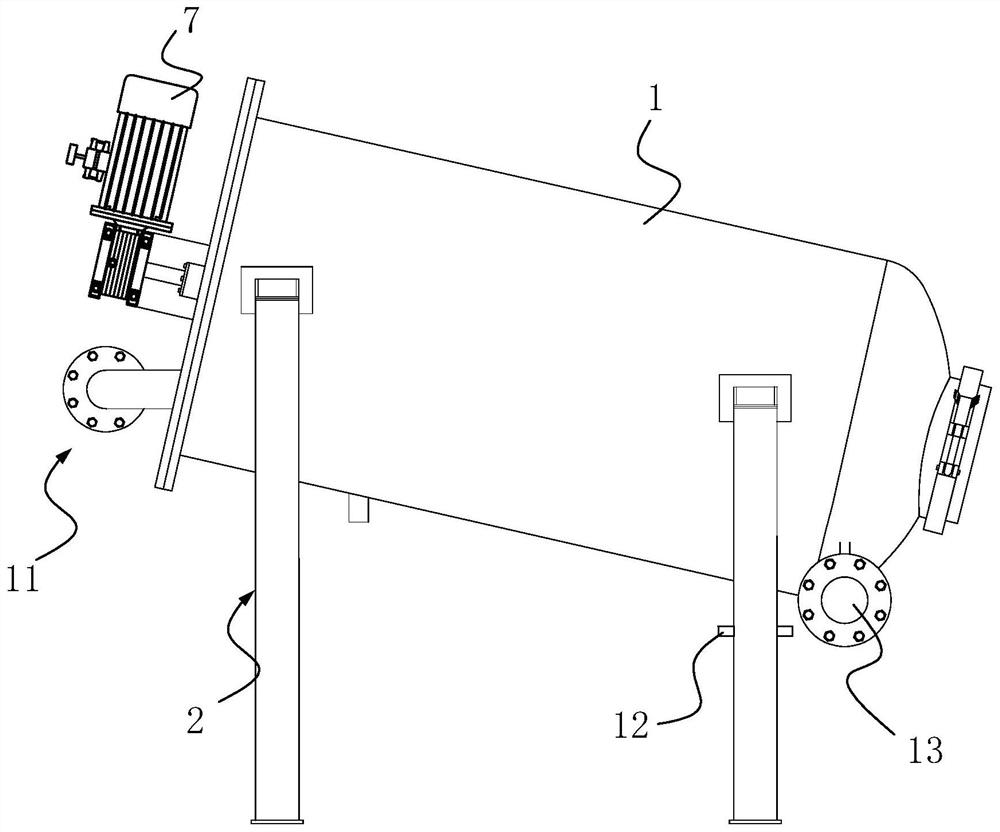

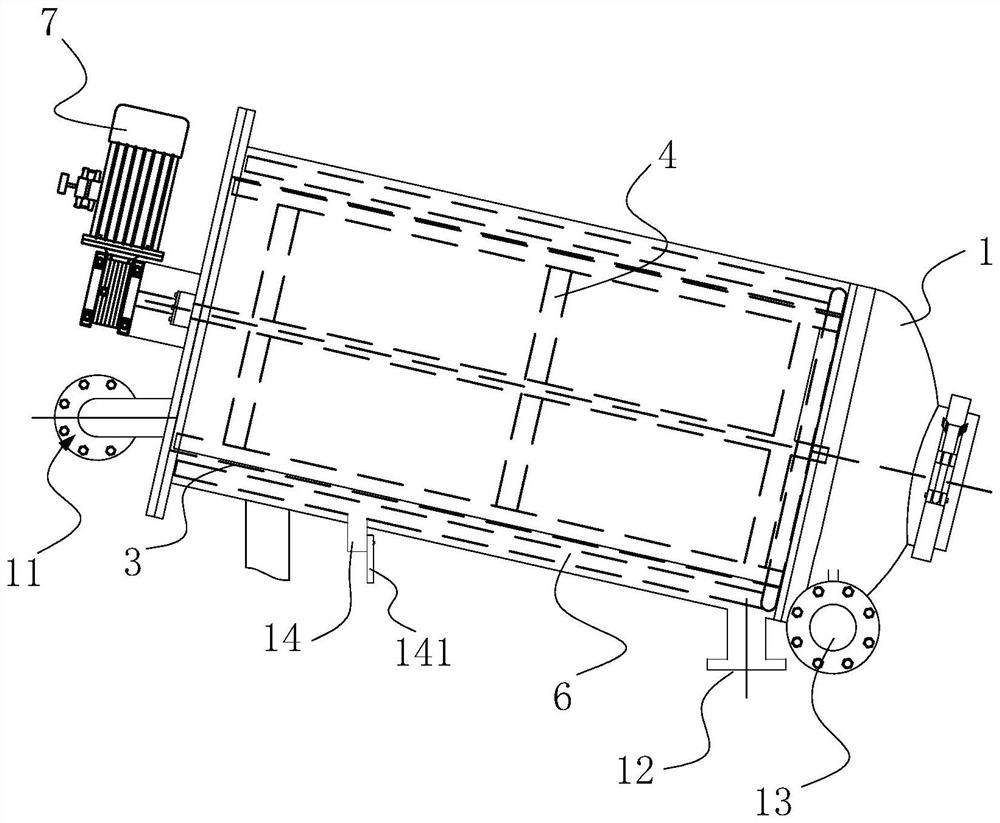

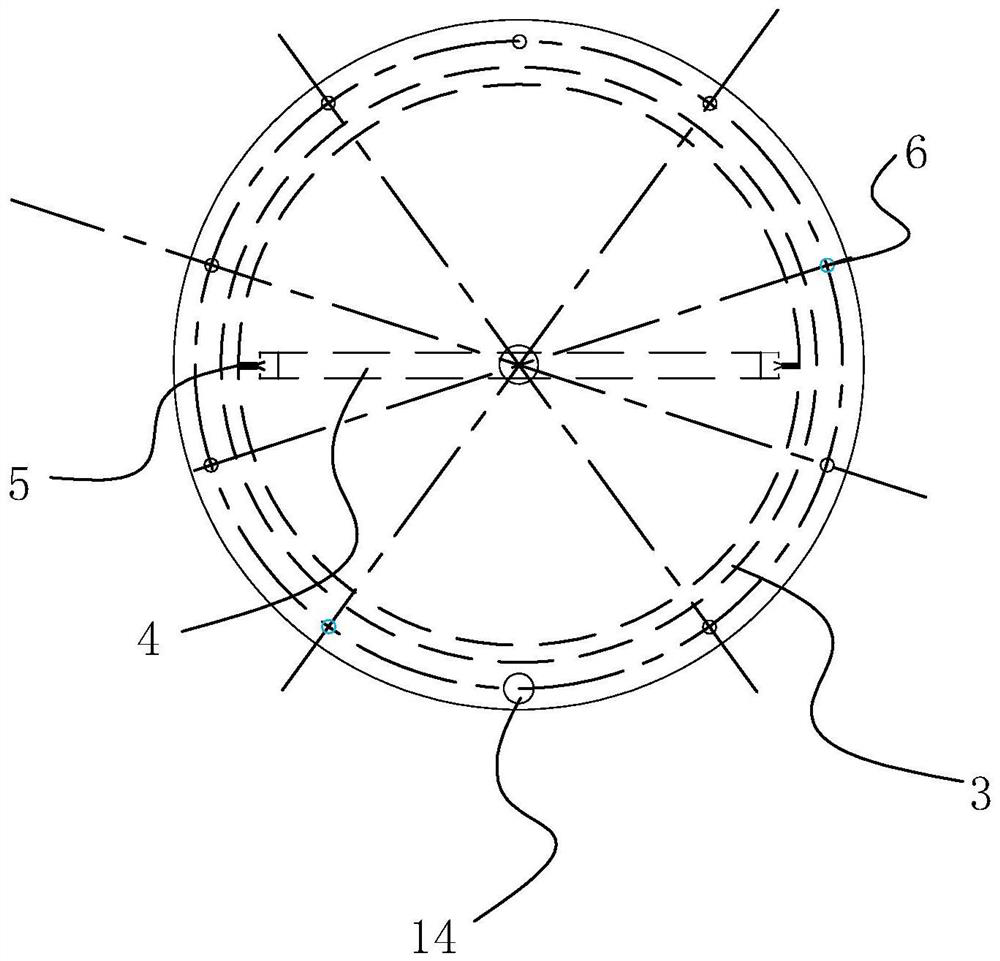

[0037] An emulsion filter, cf. figure 1, including a support frame 2, an outer cylinder 1 and a filtering device arranged inside the outer cylinder 1. The outer cylinder 1 is made of 304 stainless steel, which is sturdy and durable, and the support frame 2 is fixedly connected with the outer cylinder 1 to support the outer cylinder 1, so that the outer cylinder 1 can be tilted. One end of the outer cylinder 1 is provided with a raw liquid inlet 11 , and the other end of the outer cylinder 1 is provided with a clear liquid outlet 12 and a waste residue outlet 13 . The outer cylinder 1 is inclined downward from one end of the raw liquid inlet 11 to the clear liquid outlet 12, and the angle between the axis of the outer cylinder 1 and the horizontal plane is 10° to 15°. The waste residue outlet 13 is located at the end of the clear liquid outlet 12 away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com