Gentle dip coal seam roadway design and adjacent layer and goaf gas extraction method

A technology of gently tilting and goaf, applied in gas emission, mining equipment, earth-moving drilling, etc., can solve the problems of high cost, long cycle and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

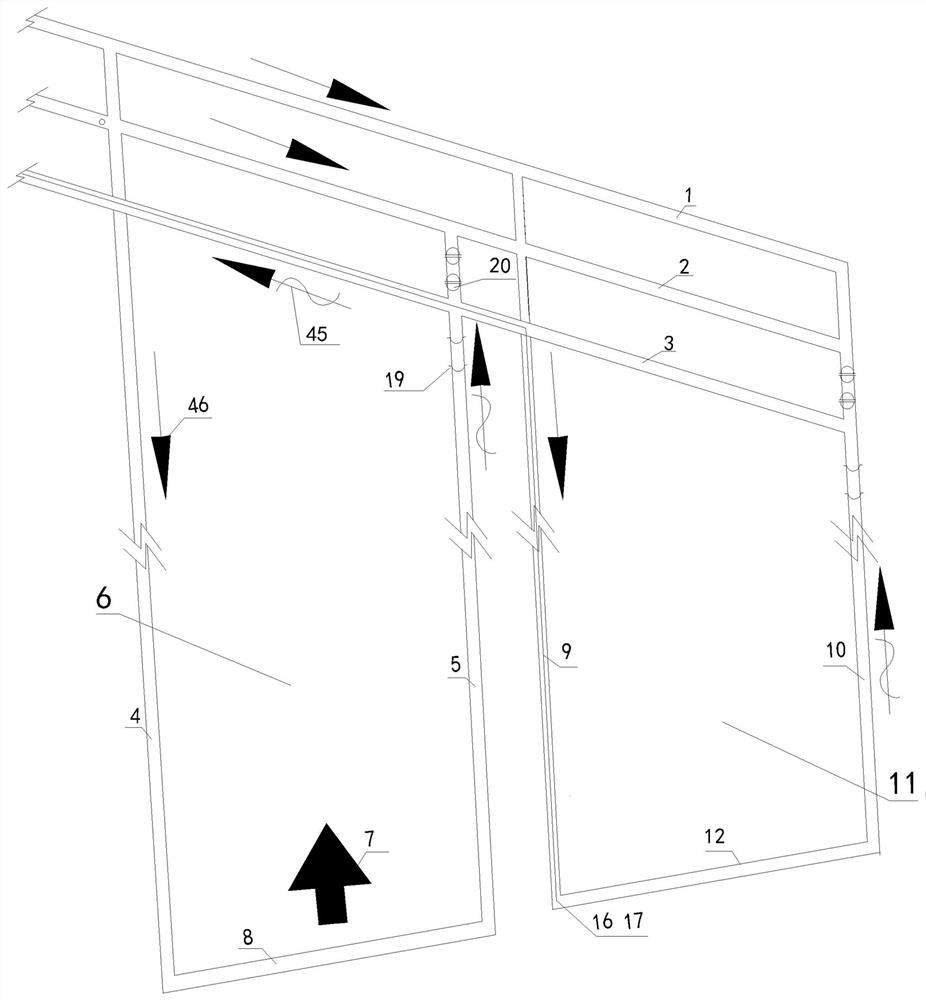

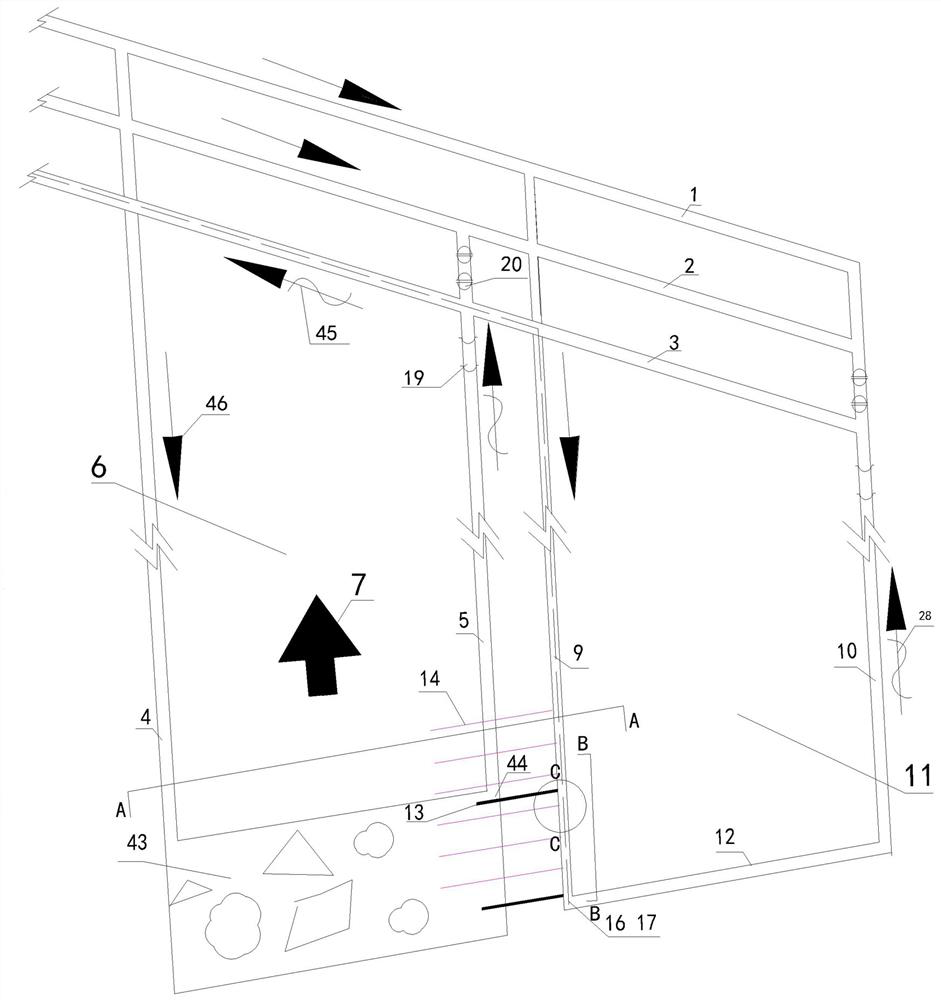

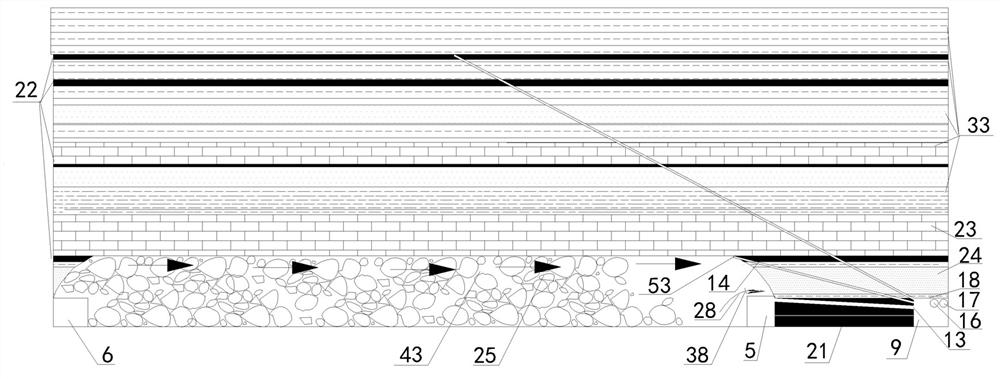

Method used

Image

Examples

example

[0183] Example: I have been working as the chief engineer since 2010. The mine I am engaged in is a high-gas mine, and the gas emission in the upper adjacent seam accounts for 70%. According to the actual situation and working conditions, the above design has been adopted.

[0184] The amount of gas emission in the mining face of the mine: the absolute gas in the mining face is 33.0m 3 / min, the relative gas emission is 13.4m 3 / t. Among them, the gas emission in the adjacent seam coal rock accounts for 70%, and the absolute gas is 23.1m 3 / min. See Table 1 for the thickness, distance and gas emission rate of the working face of the 15# coal seam in mine mining.

[0185]

[0186] In the same wing of the same mining area along the uphill direction from bottom to top, first excavate the transport trough of the coal mining face and the return air trough of the coal mining face at the same time, and then excavate the coal mining face to open the cut hole to form the coal min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com