Visual horizontal annulus rock debris migration simulation method

A simulation method and horizontal ring technology, applied in teaching models, earth-moving drilling, wellbore/well components, etc., can solve the problems of not considering the actual annular well wall roughness, complex structure, inability to simulate more realistically, etc. Ensure the reliability of the experiment, the accuracy of the experimental results, and the effect of easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

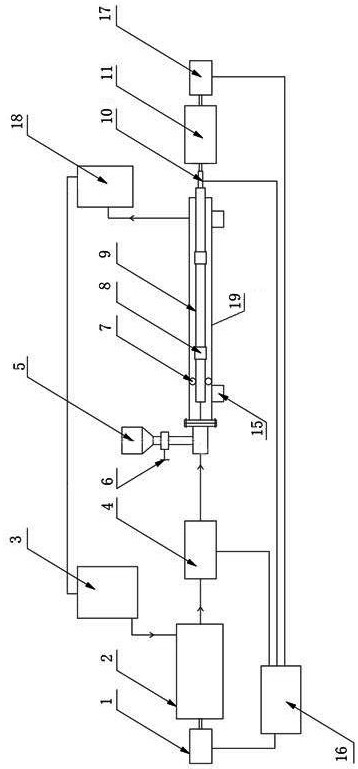

[0035] see figure 1 , a method for simulating the movement of debris in a visualized horizontal annulus, comprising the following steps:

[0036] a. Inject fluid into the annulus of the simulated wellbore 19 of the visualized horizontal annulus cuttings migration simulation equipment through the drilling fluid device, simulating the drilling fluid in the horizontal annulus of the horizontal well;

[0037] b. Regulate the amount of cuttings injected into the cuttings tank 5 by the feed control valve 6, record the amount of cuttings injected per minute, according to the readings of the liquid flow meter 4, the weight of cuttings in the cuttings separator 18, and the readings of the torque sensor 10 , The readings of the first frequency converter 1, the readings of the second frequency converter 17, the eccentricity of the drill pipe 9, the cuttings migration track and the cuttings bed start-up and settlement distance again, and analyze the influence of different cuttings amounts...

Embodiment 2

[0044] see figure 1 , a method for simulating the movement of debris in a visualized horizontal annulus, comprising the following steps:

[0045] a. Inject fluid into the annulus of the simulated wellbore 19 of the visualized horizontal annulus cuttings migration simulation equipment through the drilling fluid device, simulating the drilling fluid in the horizontal annulus of the horizontal well;

[0046] b. Regulate the amount of cuttings injected into the cuttings tank 5 by the feed control valve 6, record the amount of cuttings injected per minute, according to the readings of the liquid flow meter 4, the weight of cuttings in the cuttings separator 18, and the readings of the torque sensor 10 , The readings of the first frequency converter 1, the readings of the second frequency converter 17, the eccentricity of the drill pipe 9, the cuttings migration track and the cuttings bed start-up and settlement distance again, and analyze the influence of different cuttings amounts...

Embodiment 3

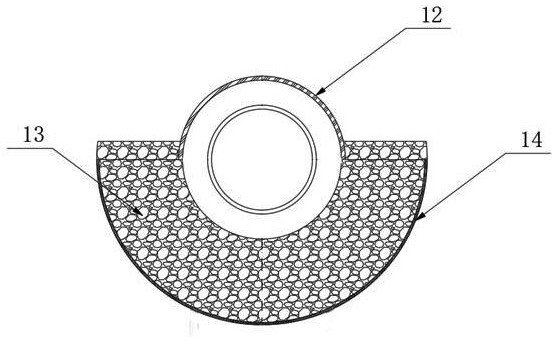

[0054] see figure 1 and figure 2 , a method for simulating the movement of debris in a visualized horizontal annulus, comprising the following steps:

[0055] a. Inject fluid into the annulus of the simulated wellbore 19 of the visualized horizontal annulus cuttings migration simulation equipment through the drilling fluid device, simulating the drilling fluid in the horizontal annulus of the horizontal well;

[0056] b. Regulate the amount of cuttings injected into the cuttings tank 5 by the feed control valve 6, record the injection amount of cuttings per minute, according to the readings of the liquid flow meter 4, the weight of cuttings in the cuttings separator 18, and the readings of the torque sensor 10 , The readings of the first frequency converter 1, the readings of the second frequency converter 17, the eccentricity of the drill pipe 9, the cuttings migration trajectory and the cuttings bed start-up and settlement distance again, and analyze the influence of diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com