Intelligent self-adaptive vibration reduction system

A vibration reduction system and self-adaptive technology, applied in roads, buildings, rails, etc., can solve the problem of continuous vibration of the damper, and achieve the effects of easy processing, reversible damping force change, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

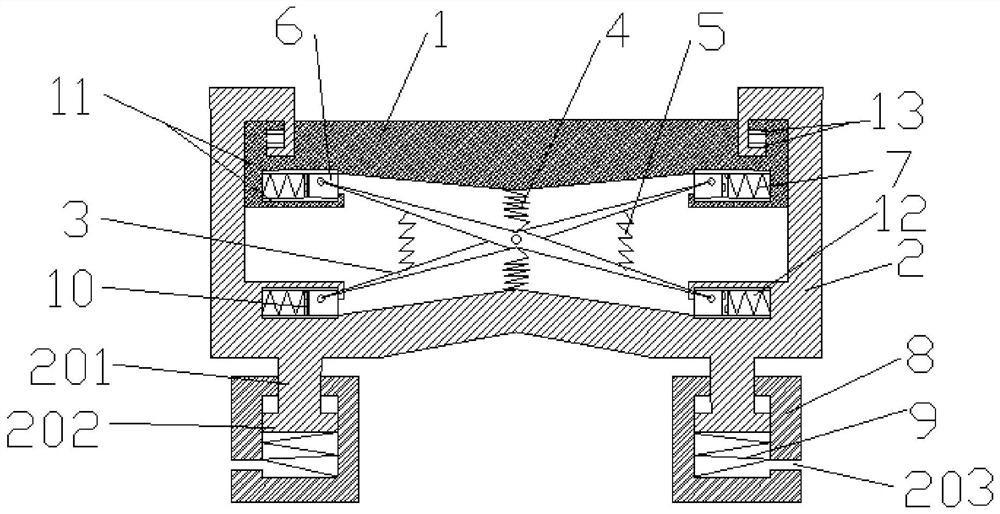

[0023] (1) Reference figure 1 , an intelligent self-adaptive damping system, comprising: an outer sleeve, the outer sleeve includes a U-shaped plate 1 and a metal outer frame 2, and both sides of the U-shaped plate 1 are embedded in the metal outer frame 2, the U-shaped plate 1 and the metal outer frame 2 are connected by a cross-type compression plate 3; the middle part of the cross-type pressure-resistant plate is hinged, and the middle part of the cross-type compression plate The two ends are respectively connected with the U-shaped plate 1 and the metal outer frame 2 through the first damping spring 4; the cross-shaped anti-pressure plate is connected between the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com