Gerbera delavayi fiber collecting method and device

A technology of fiber collection and fireweed, which is applied in fiber processing, fiber mechanical separation, plant fiber of other plant raw materials, etc., can solve the problems of difficulty in mastering manual twisting process, difficulty in quality assurance, low efficiency, etc., and achieve the goal of line production The effect of continuous process, uniform quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

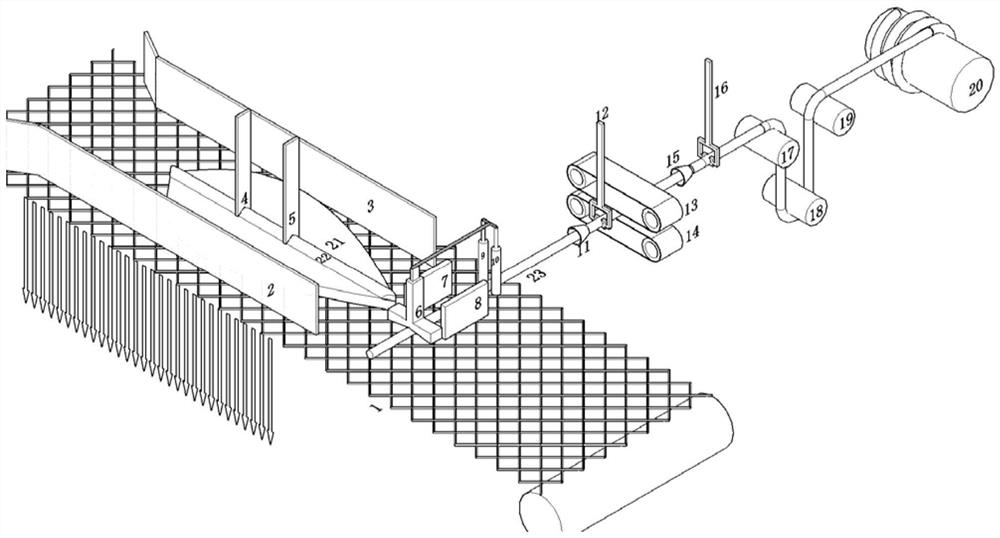

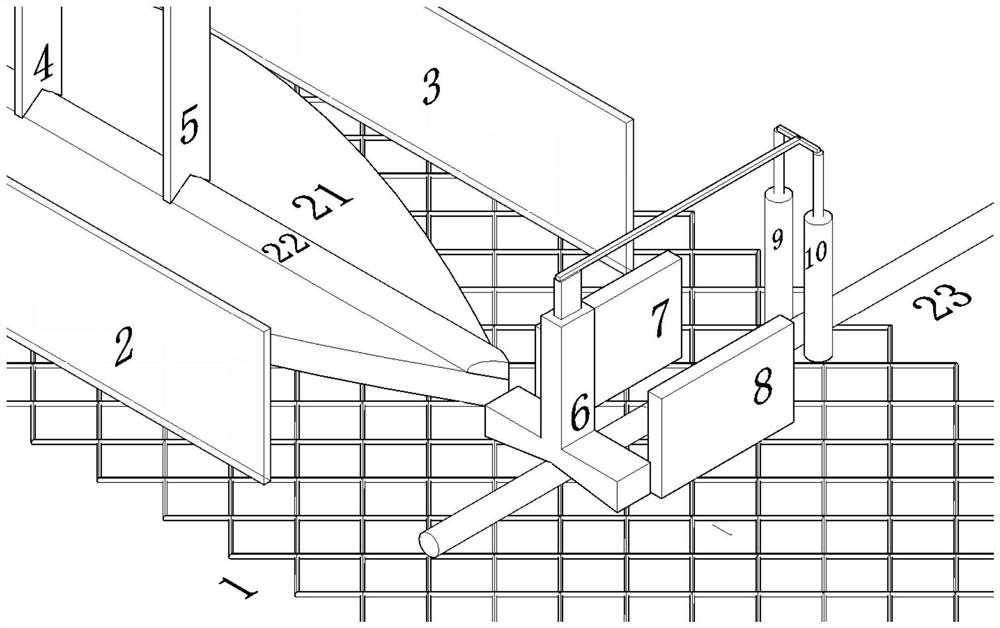

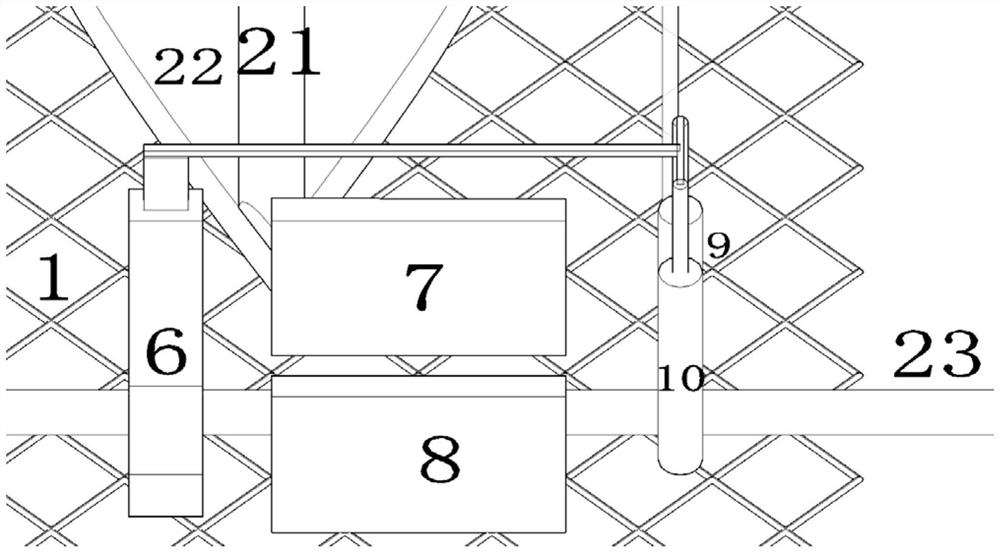

[0068] A kind of collecting method of fire grass fiber, adopts such as Figure 1-5 As shown in the collection device, the steps are as follows:

[0069](1) Place the collected fireweed blade 21 on the conveyor belt 1 with the suede side of the leaf back facing upward, between the baffle plate M2 and the baffle plate N 3, and align the midrib of the blade with the jaw J 4 and the clamp Mouth K 5, so that jaws J 4 and jaw K 5 clamp the two wings on both sides of the midrib, so that the two jaws tightly position the blade; baffle M 2, baffle N 3, jaw J 4 and jaw K 5 cooperate with each other to ensure that the blades move roughly along a straight line;

[0070] (2) Take the pre-fabricated small section of Huocao yarn from left to right along the sequence of pressure handle 6, passive roller group, bell mouth E11, chuck C12, twisting belt group, bell mouth F15 and chuck D16 Through the yarn forming component, the yarn passes between the twisting belt G13 and the twisting belt H1...

Embodiment 2

[0077] Due to the protruding midrib in the middle of the blade, the blade is divided into two halves. Using one set of yarn forming components to collect the suede on the left and right halves at the same time cannot eliminate the influence of the raised midrib. Therefore, two sets of yarn forming components are required to collect the left and right halves respectively. Suede on half sheet. In this example, the positioning assembly and the conveying assembly are as in embodiment 1, except that there is one more set of yarn forming assemblies than in embodiment 1, and the setting direction of the new yarn forming assembly and the threading direction of the yarn are opposite to those of the original assembly. Simultaneously, the position of the new yarn-forming component in the longitudinal direction is slightly behind the old yarn-forming component, so that two sets of yarn-forming components can simultaneously perform yarn-forming operations on the two halves of the fire grass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com