Method for removing impurities from nickel solutions using reusable polymetallic salts as complexing agents

A multi-metal salt and nickel solution technology, which is applied in the direction of improving process efficiency, can solve the problems of not being able to achieve deep desiliconization and increase the burden of impurity removal in subsequent processes, and achieve the effects of low cost, good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

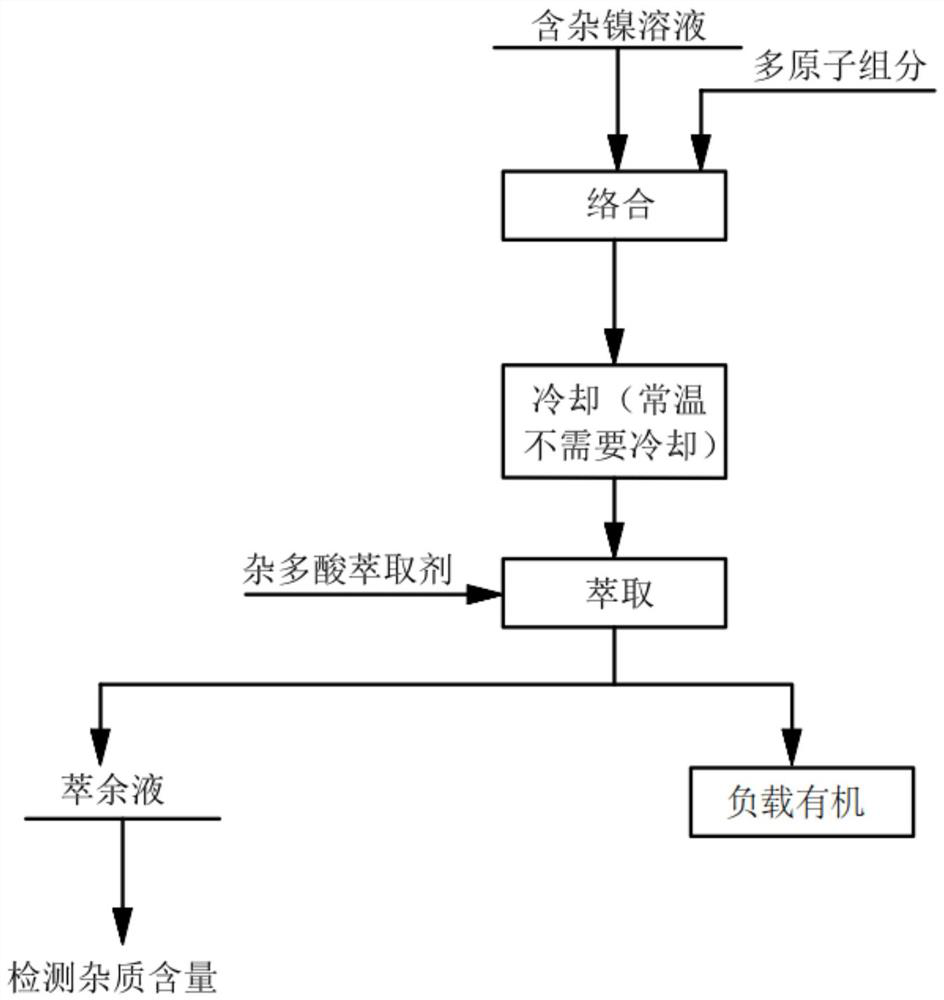

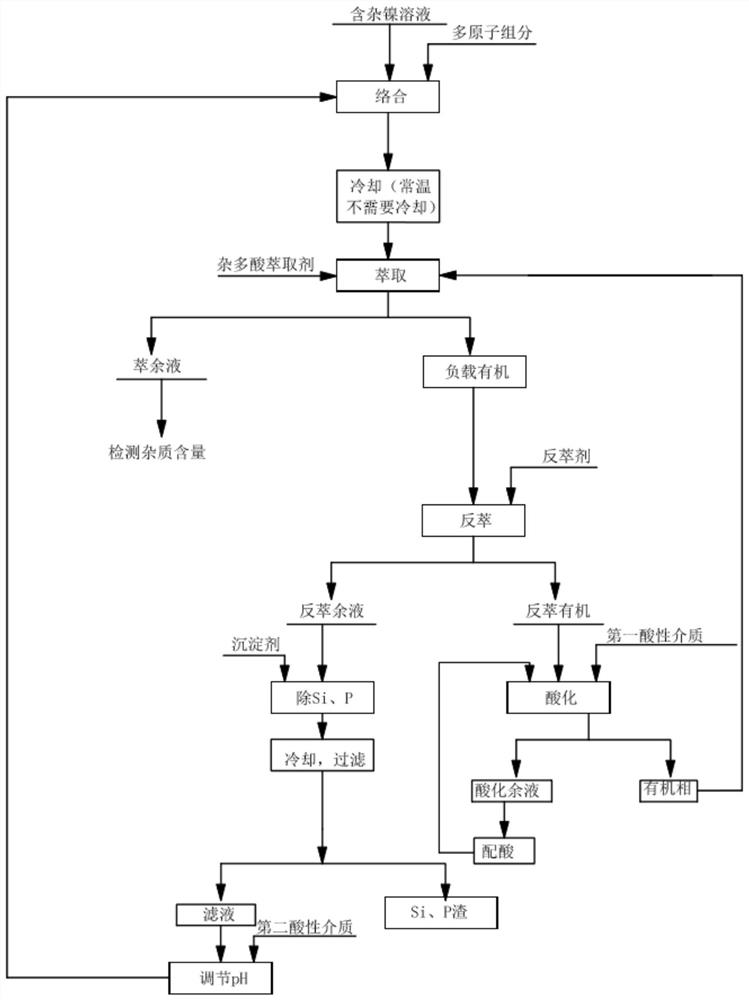

Method used

Image

Examples

Embodiment approach 1

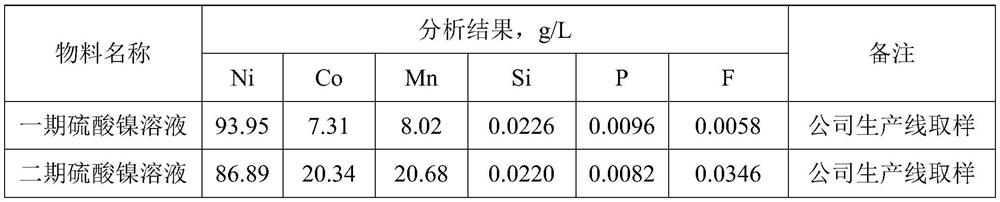

[0138] Add sodium molybdate with 1.5 times the molar content of Si and P heteroelements to the nickel solution, adjust the pH value of the nickel solution to 3.0, stir at room temperature for 1 hour, and then add the volume component ratio of 10% N235+30% isooctanol+ 60% kerosene heteropolyacid extractant, the volume ratio of the addition amount of the heteropolyacid extractant to the nickel solution is 1:1, and after mixing 5min, stand for stratification, and the raffinate (nickel) with Si, P impurity content below 1ppm is obtained by separation. solution) and organic phase.

Embodiment approach 2

[0140] Add ammonium molybdate with 1.5 times the molar content of Si and P heteroelements to the nickel solution, adjust the pH value of the nickel solution to 4.0, stir at room temperature for 1 hour, and then add the volume component ratio of 5% N235+50% sec-octanol+ 45% kerosene heteropolyacid extractant, the volume ratio of the addition amount of the heteropolyacid extractant to the nickel solution is 1:1, and after mixing 10min, it is left to stand for stratification, and the raffinate (nickel) with Si, P impurity content below 1ppm is obtained by separation solution) and organic phase.

Embodiment approach 3

[0142] Add potassium molybdate with 1.3 times the molar content of Si and P heteroelements to the nickel solution, adjust the pH value of the nickel solution to 2.0, stir for 2 hours at room temperature, and then add the volume component ratio of 20% N235+50% n-octanol+ 30% kerosene heteropolyacid extractant, the volume ratio of the addition amount of the heteropolyacid extractant to the nickel solution is 1:1, and after mixing 15min, stand for stratification, and the raffinate (nickel) with Si, P impurity content below 1ppm is obtained by separation. solution) and organic phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com