A kind of compound and organic electroluminescent device

A compound and luminescent technology, applied in the direction of electric solid-state devices, organic chemistry, luminescent materials, etc., can solve the problems of insufficient development of organic electroluminescent materials and backward panel manufacturing enterprises, so as to improve service life and luminous efficiency, and increase molecular weight , the effect of improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

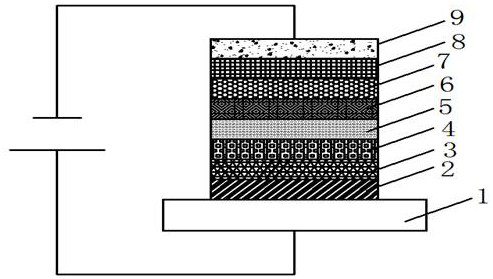

Image

Examples

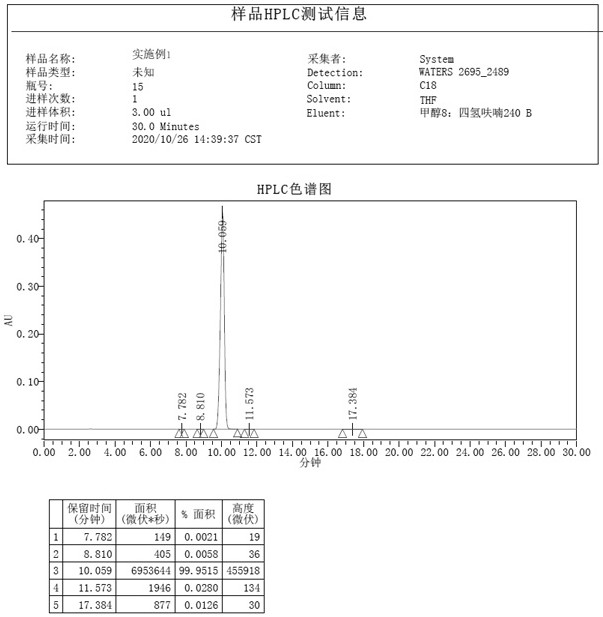

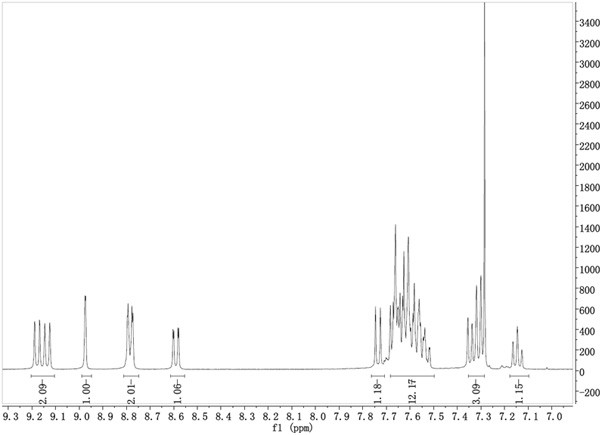

Embodiment 1

[0051]

[0052] The preparation method of compound 1 is as follows:

[0053]

[0054]S1: Under nitrogen protection, compound 1-a (10g, 226.06g / mol, 44.24mmol), compound 1-b (1.1eq, 11.84g, 243.30g / mol, 48.66mmol), sodium tert-butoxide (1.1eq , 4.68g, 96.1g / mol, 48.66mmol), tris(dibenzylideneacetone)dipalladium (0.05eq, 2.02g, 915g / mol, 2.21mmol), tri-tert-butylphosphine (0.05eq, 0.45g, 202.32g / mol, 2.21mmol), toluene (100ml) were added to the reaction flask, after the addition was completed, the temperature was raised to reflux for 5 hours, after the reaction was completed, the temperature was lowered to room temperature, and water (100ml) was added and stirred for 15 minutes to obtain the filtrate, which was passed through diatom The organic phase was obtained by liquid separation after soil filtration. The organic phase was dried with anhydrous magnesium sulfate and spin-dried, and purified by column chromatography to obtain compound 1-c (12.12g, yield 63.3%), ESI-MS (...

Embodiment 2

[0057]

[0058] The preparation method of compound 3 is as follows:

[0059]

[0060] The preparation method is basically the same as in Example 1, the difference is that compound 1-b is replaced by compound compound 2-b, and the reaction gives compound 3 (yield 71.7%), ESI-MS (m / z) (M+): theoretical value 645.76 , measured value 646.30, elemental analysis results (molecular formula C45H23D5N4O): theoretical value C, 83.70; H, 5.15; N, 8.68; O, 2.48; measured value C, 83.70; H, 5.15; N, 8.68; O, 2.48.

Embodiment 3

[0062]

[0063] The preparation method of compound 4 is as follows:

[0064]

[0065] The preparation method is basically the same as in Example 1, the difference is that compound 3-b is used to replace compound 1-b, and the reaction gives compound 4 (yield 71.5%), ESI-MS (m / z) (M+): theoretical value 645.76 , measured value 646.62, element analysis results (molecular formula C45H23D5N4O): theoretical value C, 83.70; H, 5.15; N, 8.68; O, 2.48; measured value C, 83.70; H, 5.14; N, 8.68; O, 2.48.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com