Clamping device for forklift accessory machining

A technology for clamping devices and accessories, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of the outer surface of hardware accessories, such as depression, unfavorable accessories production and processing operations, and unfavorable accessories production and processing efficiency. Good fixing effect, good clamping and fixing effect, and the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

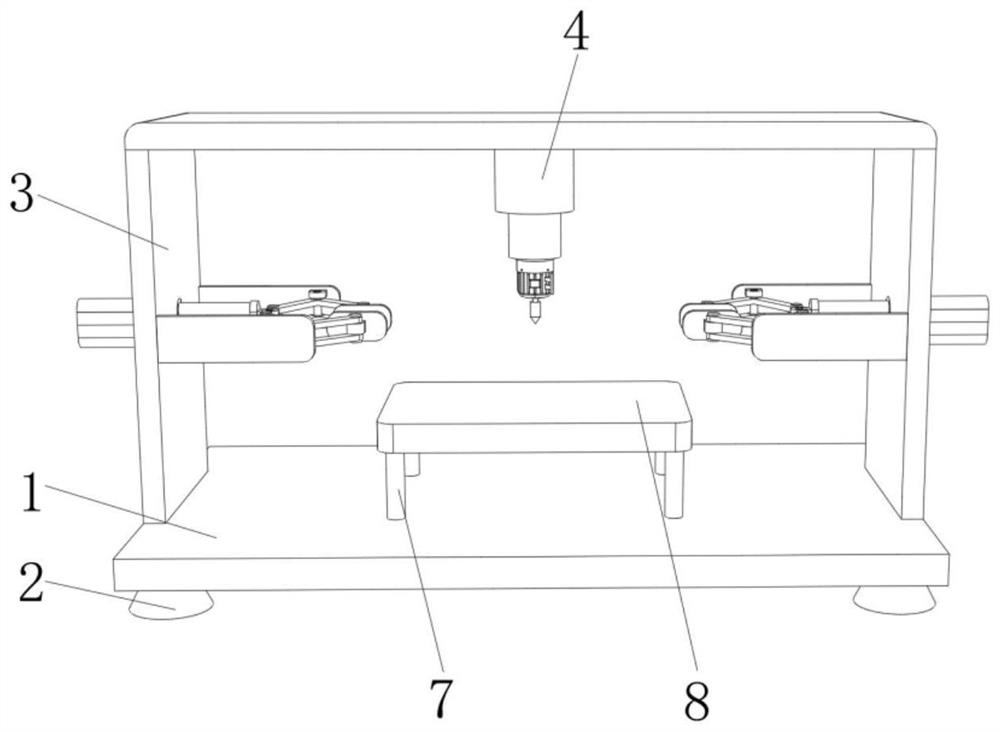

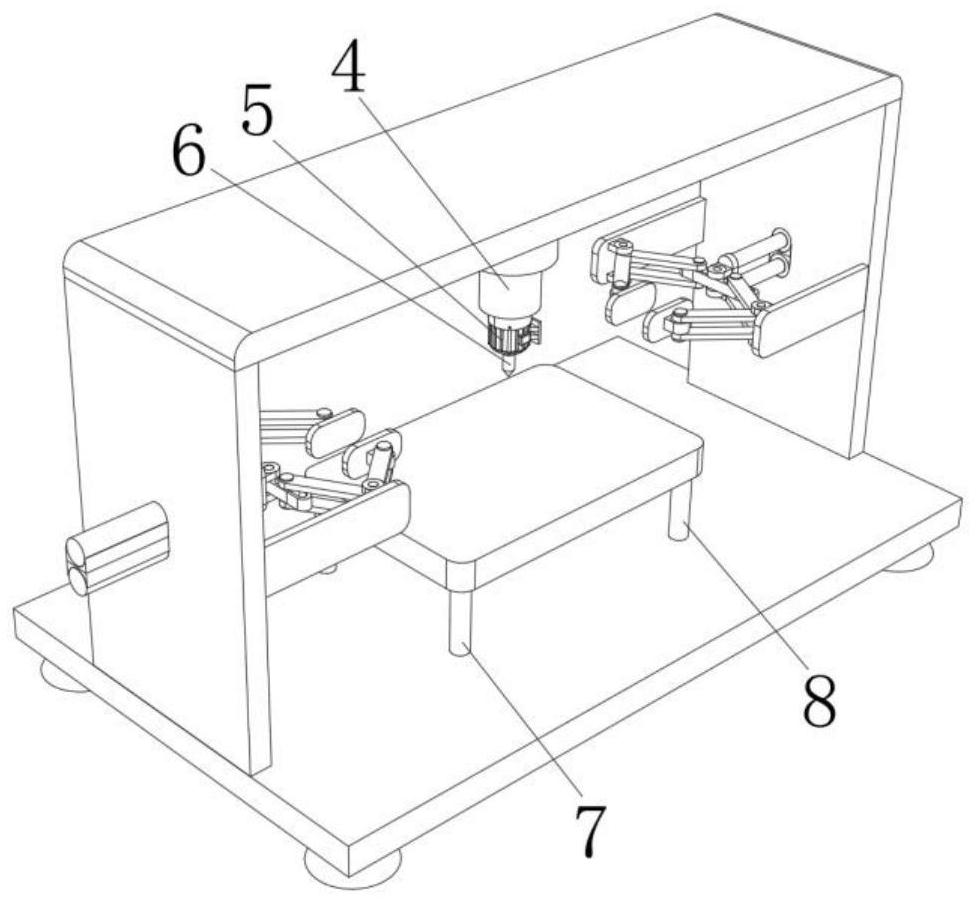

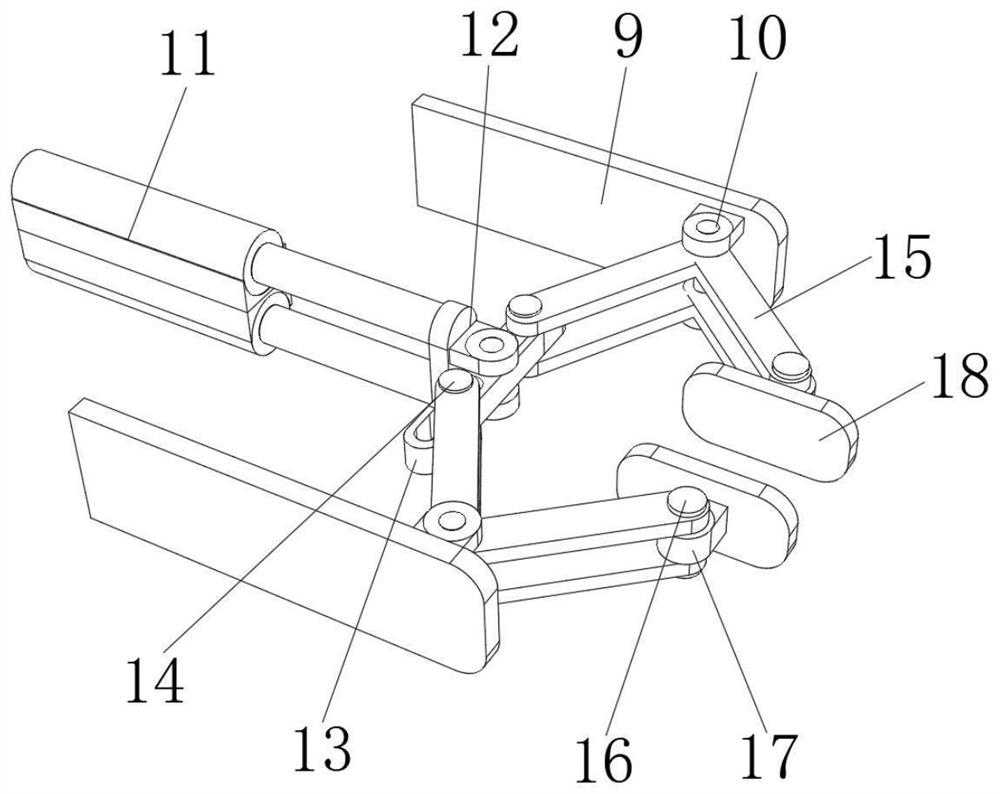

[0024] see Figure 1-3 , the present invention provides a technical solution: a clamping device for forklift parts processing, including a fixed base plate 1, the four corners of the lower surface of the fixed base plate 1 are fixedly connected with a fixed base 2, and the upper surface of the fixed base plate 1 is fixedly connected There is a gantry 3, the top inner wall of the gantry 3 is fixedly connected with a first electric push rod 4, the specific model of the first electric push rod 4 is LAP22, the output end of the first electric push rod 4 is fixedly connected with a drilling motor 5, and the drill The specific model of the hole motor 5 is 130BYG350, the output end of the drilling motor 5 is fixedly connected with a drill bit 6, the upper surface of the fixed bottom plate 1 is fixedly connected with a support column 7, and the upper surface of the support column 7 is fixedly connected with a placement plate 8, a gantry 3 The inner walls of the left and right sides ar...

Embodiment 2

[0033] see Figure 1-2 and Figure 4 , the present invention provides a technical solution: a clamping device for forklift parts processing, including a fixed base plate 1, the four corners of the lower surface of the fixed base plate 1 are fixedly connected with a fixed base 2, and the upper surface of the fixed base plate 1 is fixedly connected There is a gantry 3, the top inner wall of the gantry 3 is fixedly connected with a first electric push rod 4, the specific model of the first electric push rod 4 is LAP22, the output end of the first electric push rod 4 is fixedly connected with a drilling motor 5, and the drill The specific model of the hole motor 5 is 130BYG350, the output end of the drilling motor 5 is fixedly connected with a drill bit 6, the upper surface of the fixed base plate 1 is fixedly connected with a support column 7, and the upper surface of the support column 7 is fixedly connected with a placement plate 8.

[0034] In the present invention, in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com