A dispensing device for battery processing and its working method

A technology of dispensing device and battery, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of dripping glue, unstable temperature, high energy consumption, etc., achieve stable dispensing, prevent waste of energy, The effect of preventing glue from solidifying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

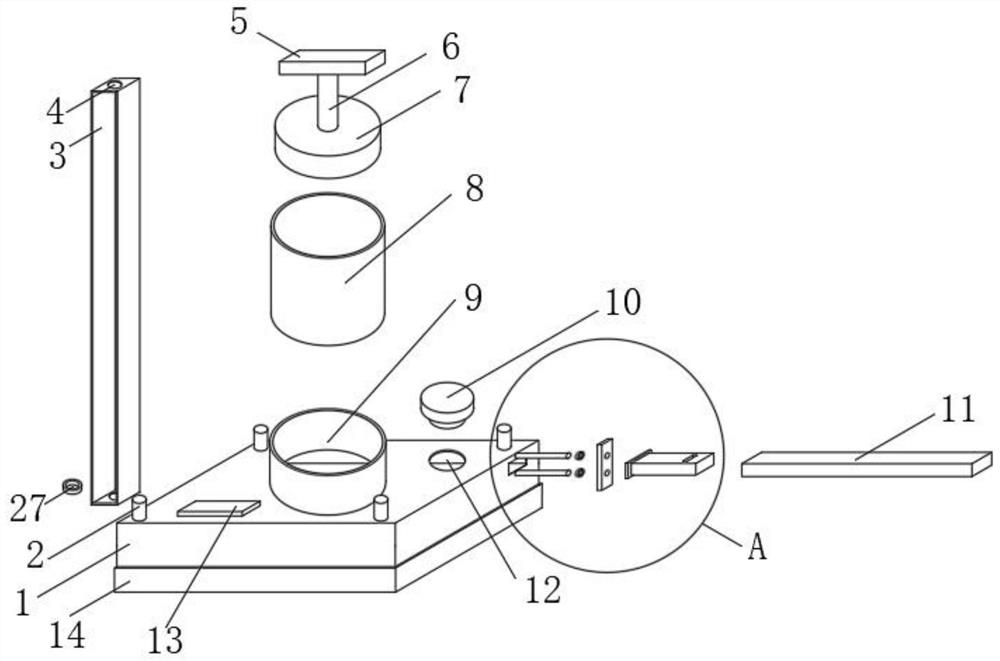

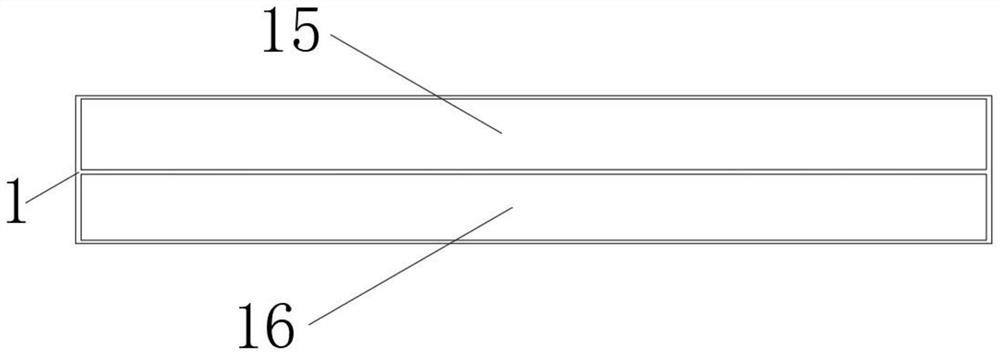

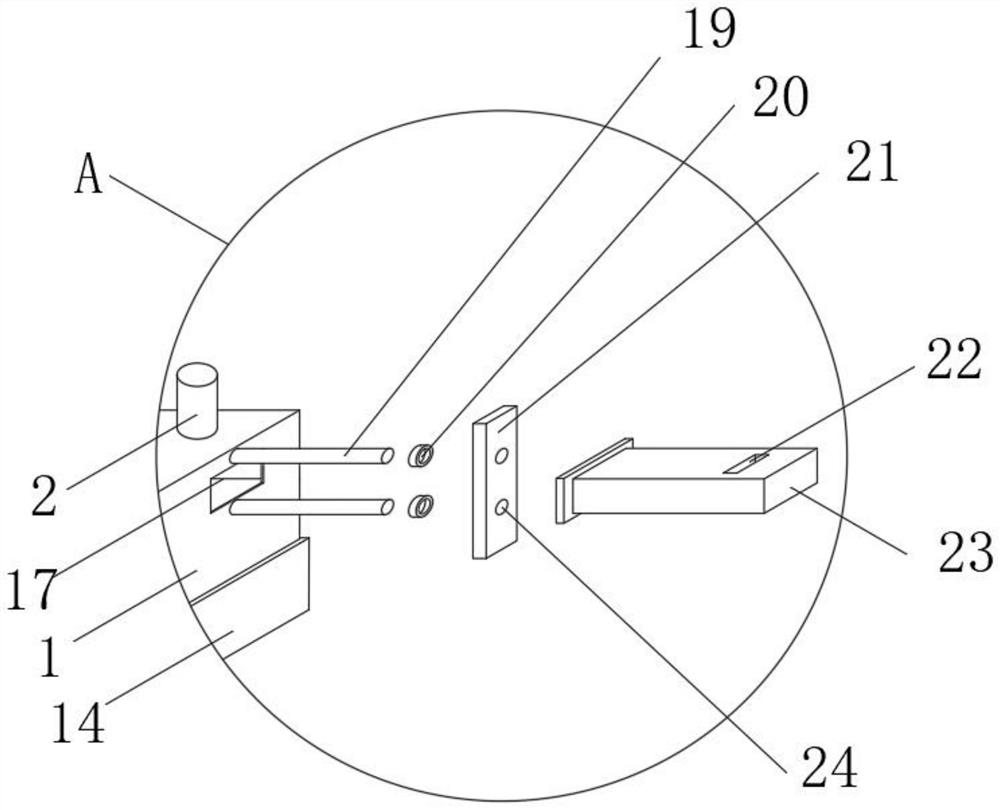

[0032] In a typical implementation of the present application, such as Figure 1-6 As shown, a dispensing device for battery processing includes a dispensing box 1, the dispensing box 1 is a rectangular structure, the inside of the dispensing box 1 is composed of a glue chamber 15 and a mold 16, and the glue chamber 15 is hollow Rectangular structure, the interior of the glue chamber 15 is provided with a heating net 25, the side wall of the glue chamber 15 is fixedly installed with a temperature sensor 26, and the middle part of the top surface of the dispensing box 1 is fixedly installed with a connecting column 9, and the connecting column 9 is open at both ends The cylindrical structure, the top surface of the dispensing box 1 covered by the bottom surface of the connecting column 9 is open, the inner wall of the connecting column 9 is provided with internal threads, and the connecting column 9 is provided with a cylinder 8, which is open at both ends. Cylindrical structur...

Embodiment 2

[0040] In order to overcome the deficiencies in the prior art, the present invention also provides a working method of a dispensing device for battery processing, the specific steps are as follows:

[0041] S1: Fill the required glue into the glue chamber 15 through the glue inlet 12, monitor the temperature through the temperature sensor 26, adjust the heating net 25, and observe the value on the display 13, so that the temperature in the glue chamber 15 is kept above the melting point of the glue to prevent The glue sets, but it should not be too high to prevent wasting energy.

[0042] S2: Monitor the pressure through the baroreceptor 18, which can be observed through the display 13, and the pressure value and temperature value will also be transmitted to the computer. The computer controls the machine and the power supply to adjust the pressure and temperature, and ensures the pressure and temperature as much as possible. Constant, and just the pressure so that the glue do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com