Environment-friendly double-sided paint spraying equipment for interior and exterior of automobile door

A technology for car doors and painting equipment, which is applied in the direction of spraying devices and liquid spraying devices, which can solve the problems of low painting efficiency, inability to reuse, and inability to reverse the inside and outside, so as to reduce the workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

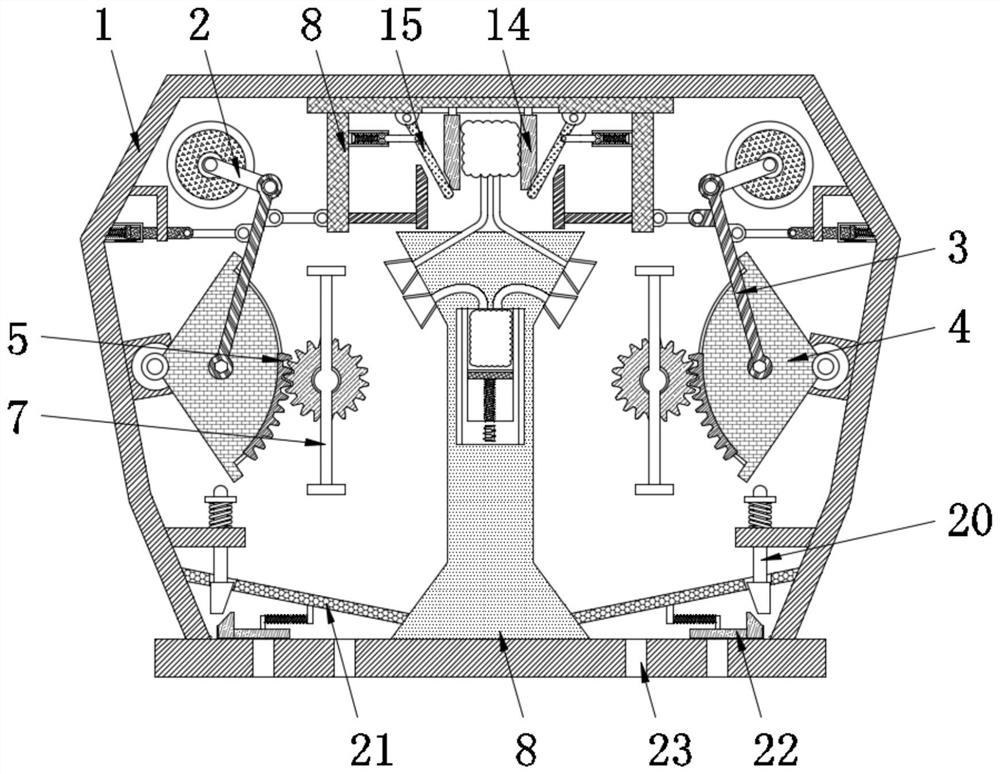

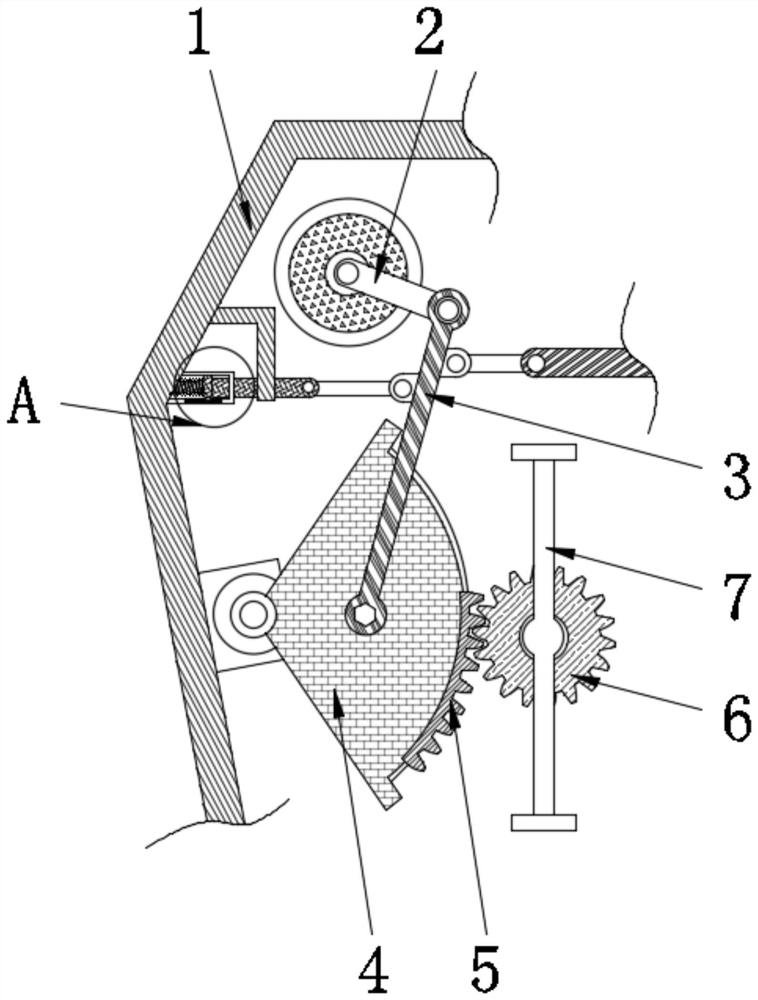

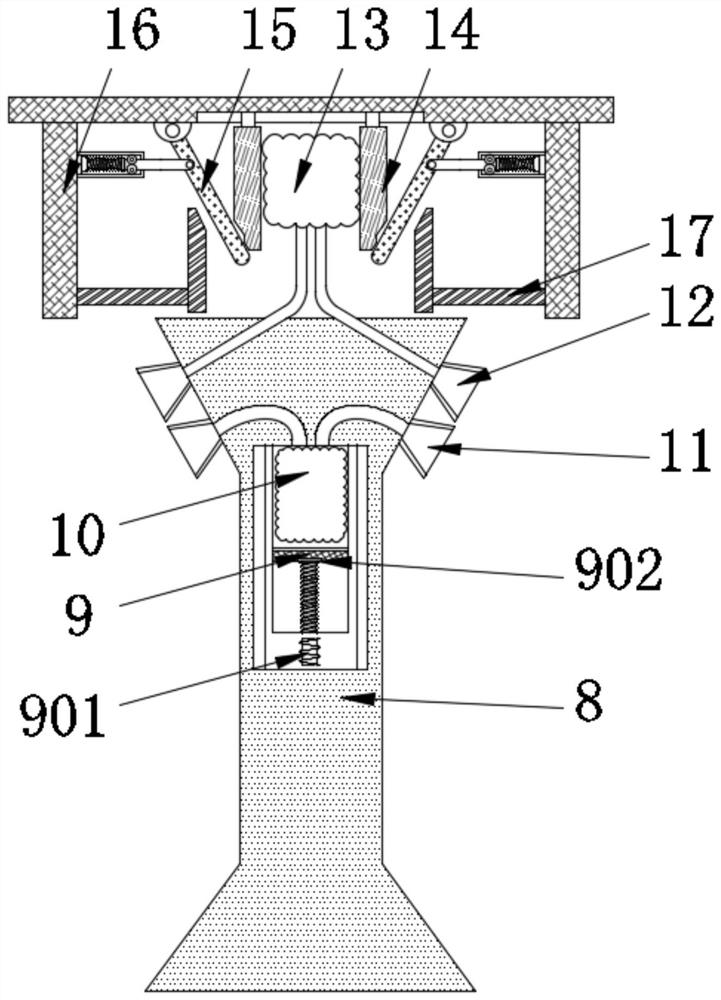

[0022] The invention provides an environment-friendly double-sided painting equipment for the interior and exterior of automobile doors, as attached figure 1 to attach Figure 5 Shown: including the processing chamber 1, the inner rotation of the processing chamber 1 is installed with the connecting plate 2, the bottom end of the connecting plate 2 is movably connected with the movable rod 3, the top of the connecting plate 2 is fixedly installed on the output end of the motor, and the connecting plate 2 The length of the movable rod 3 is less than the length of the movable rod 3. The bottom end of the movable rod 3 is fixedly equipped with a fan-shaped plate 4, and the outer surface of the fan-shaped plate 4 is slidably installed with a rack 5. The radian of the rack 5 matches the surface radian of the fan-shaped plate 4. The outer end of the fan-shaped plate 4 is movably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com