Coal mill static radial separator capable of remotely adjusting pulverized coal fineness online

A pulverized coal fineness and separator technology, which is applied in the direction of block/powder supply/distribution, combustion methods, mechanical equipment, etc., can solve the problems of difficult maintenance, heavy adjustment workload, poor site environment, etc., and achieve Avoid static separators and dynamic separators, the effect of strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below in conjunction with accompanying drawing:

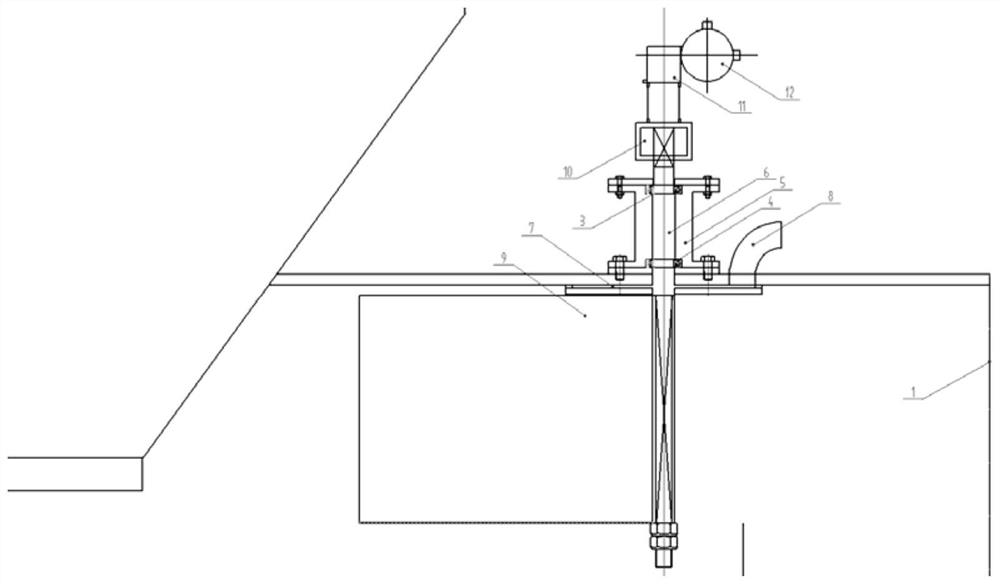

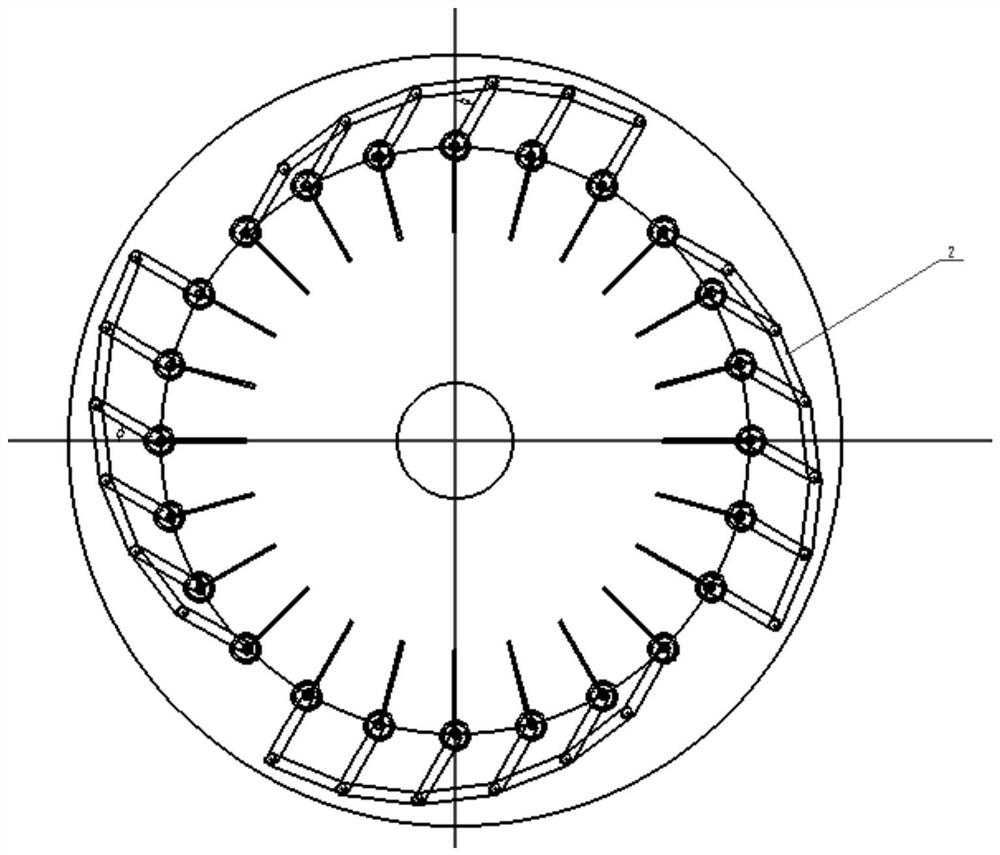

[0017] refer to figure 1 and figure 2 According to the present invention, the coal mill static radial separator that can realize online remote adjustment of coal fineness includes a coal mill separator shell 1, an electric control system, a baffle adjustment mechanism, and several separator baffles 9; The separator baffles 9 are located in the separator housing 1 of the coal mill, and all the separator baffles 9 are divided into several groups, wherein one group of separator baffles 9 corresponds to an electric control system and a baffle adjustment mechanism, and the baffles The adjustment mechanism includes several central shafts 6, and the electric control system includes a controller 11, a signal source 12 and a rotary actuator 10, wherein a central shaft 6 corresponds to a separator baffle 9, and the signal source 12 and the input end of the controller 11 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com