Heating cooking utensil

A heater and cooker technology, which is applied to electric heating fuel, lighting and heating equipment, electric/magnetic/electromagnetic heating, etc., can solve the problems of inability to cook a large number of heated objects, dark roasting, and time-consuming heating. The effect of inhibiting the drying of the food surface and the uneven grilling, the good finished product state, and the reduction of heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, an embodiment of the present invention will be described with reference to the accompanying drawings, and components with the same names as those in the prior art embodiment will be given the same reference numerals and their descriptions will be omitted.

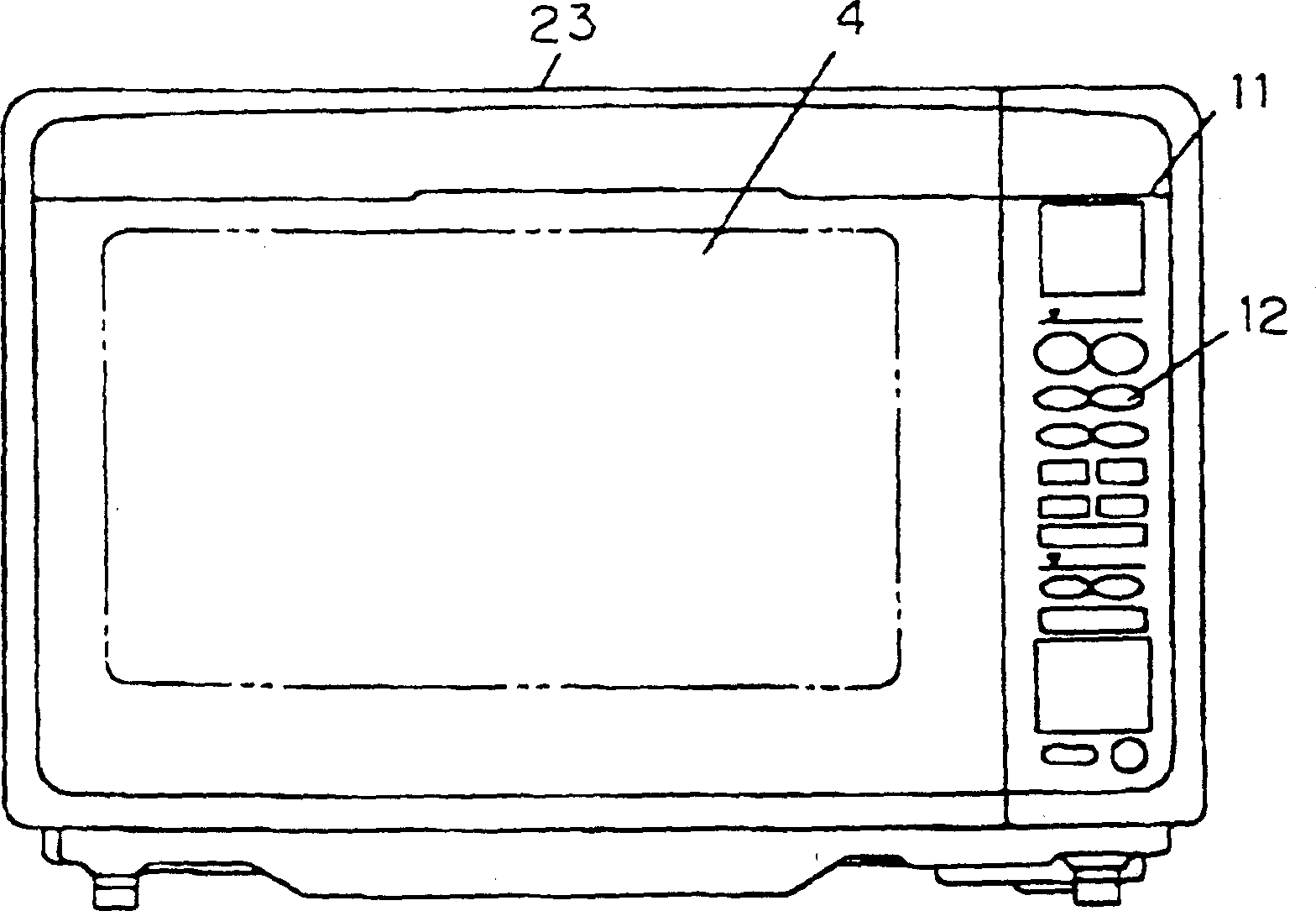

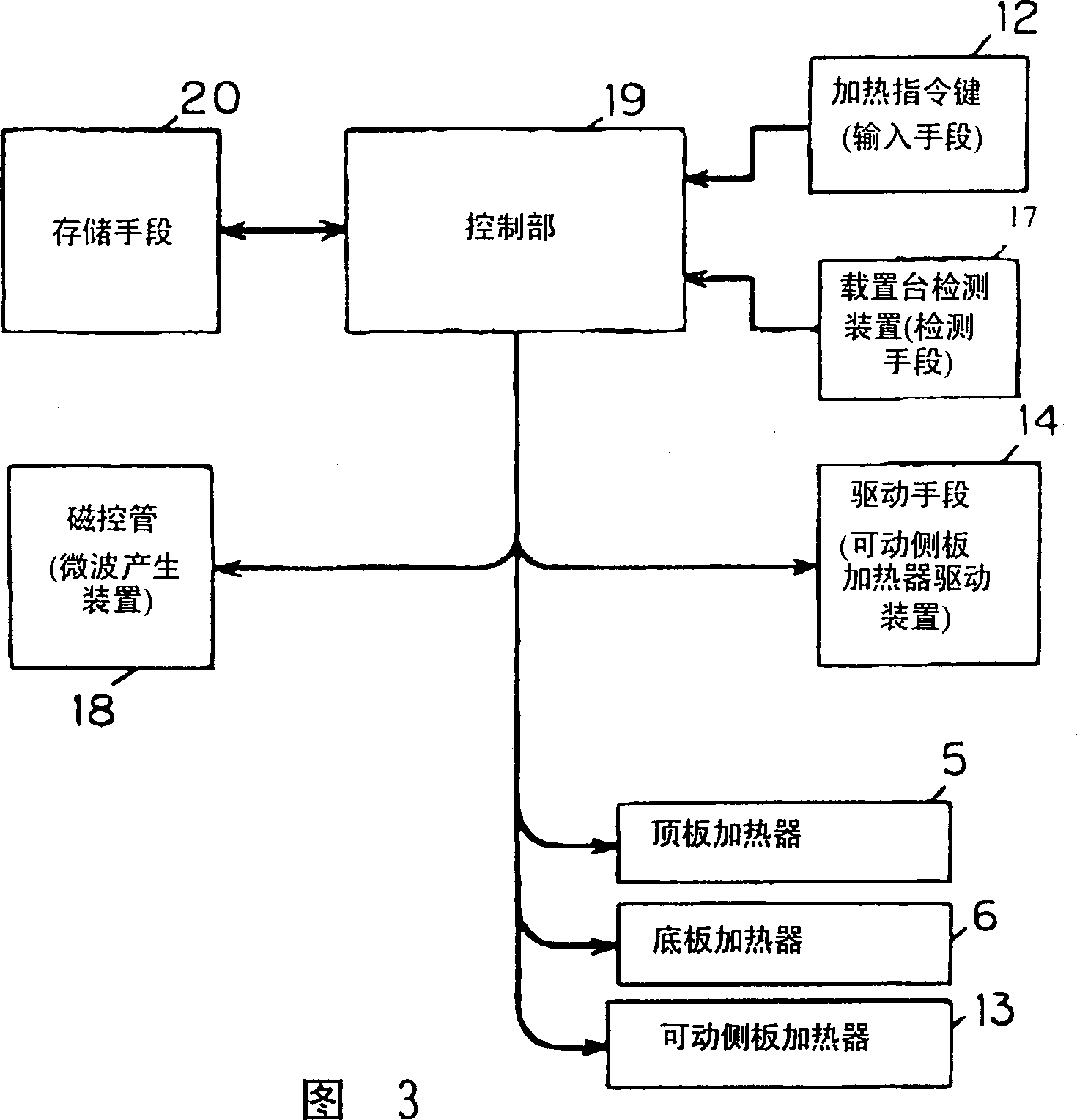

[0033] figure 2 It is an external view of the heating cooker according to the food heating method of the present invention. That is, the door 4 is pivotally supported on the front surface of the furnace body 23 so as to be openable and closable, and closes the opening of the heating chamber for accommodating food. A heating command key 12 as an input device is arranged on the operation panel 11, and a heating method is selected based on a code input through the heating command key 12 and information from a stage detection device described later, and a command is issued to the control unit.

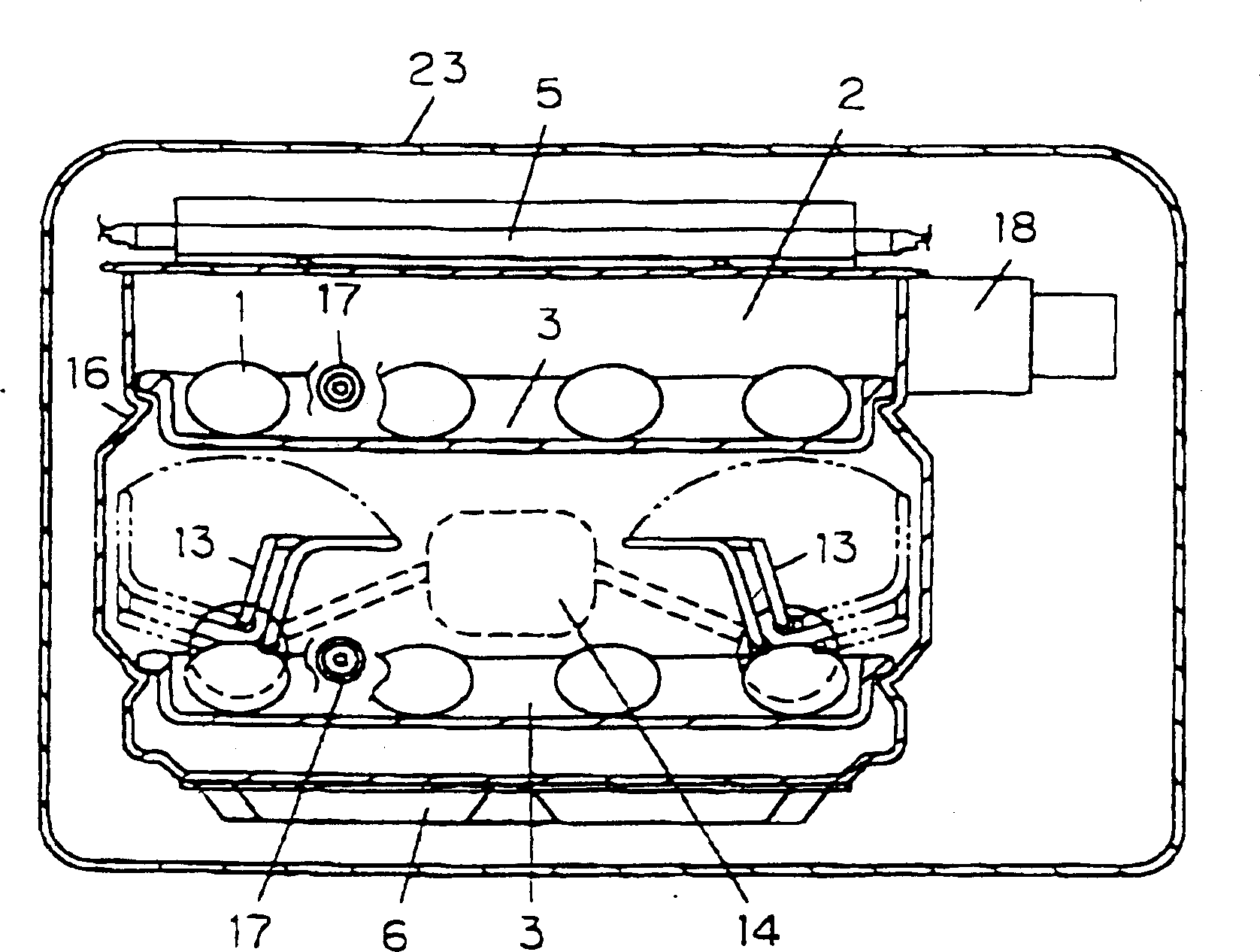

[0034] figure 1 It is a front sectional view of the heating chamber. In the heating chamber 2, a top plate he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com