Planter intelligent control system and its control method

An intelligent control system and technology for seeders, which are applied in general control systems, control/regulation systems, and program control in sequence/logic controllers, etc., can solve problems such as increased workload, difficulty in troubleshooting, and complicated and tedious operation processes. , to achieve the effect of improving seeding efficiency, solving side row replay, and simple and effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

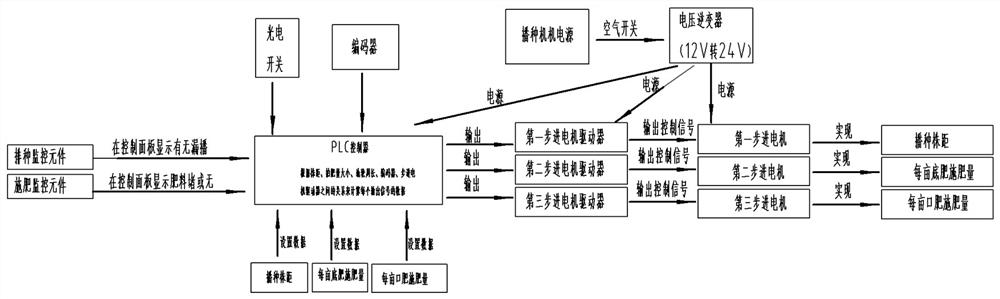

[0052] Embodiment 1 A planter intelligent control system

[0053] In this embodiment, a stepping motor is used to drive the seed metering device 4 and the fertilizer applicator to rotate, and the control of the stepping motor is realized through a PLC program. During the progress of the seeder, the planting distance and the amount of fertilizer applied per mu can be accurately controlled, thereby achieving precise sowing. requirements.

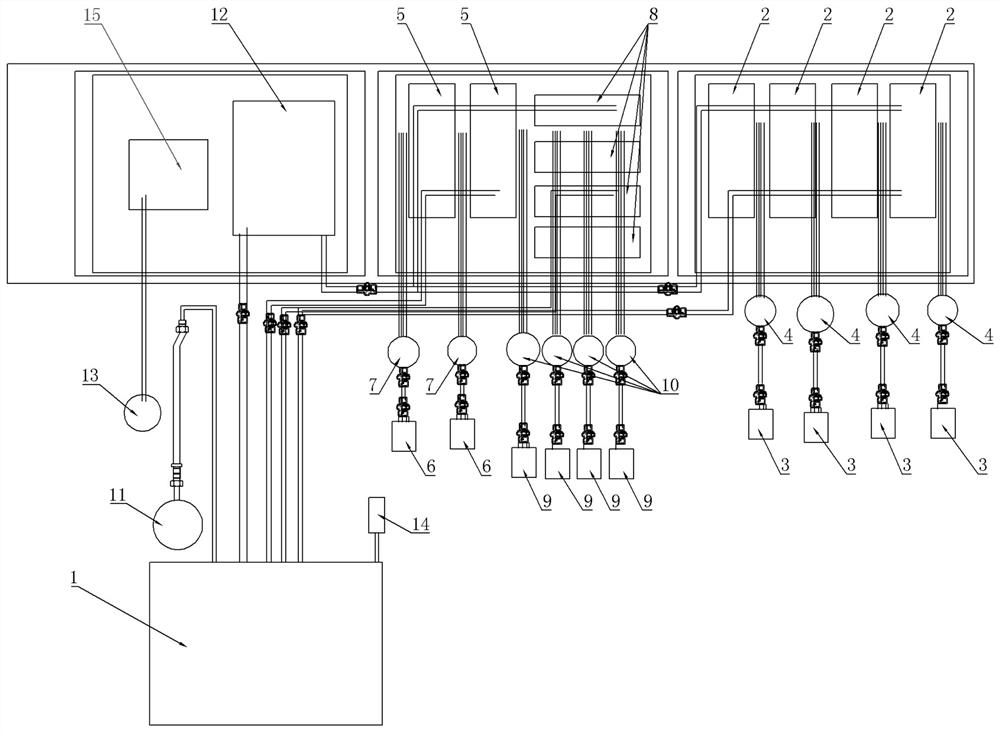

[0054] like Figure 1 to Figure 2 As shown, this embodiment includes a control unit, an execution unit and a monitoring unit.

[0055] 1. Execution unit

[0056] The execution unit is used to drive the fertilizer applicator and the seed metering device 4 to rotate, so as to complete the work of fertilization and seed metering. The execution unit includes a first drive mechanism and a second drive mechanism respectively connected to the output port of the control unit, wherein the first drive mechanism is power-connected with the seed meter ...

Embodiment 2

[0068] Example 2 A method of precisely controlling the fertilization and seeding of the seeder

[0069] This embodiment utilizes the planter intelligent control system described in Embodiment 1, including the following steps carried out in sequence:

[0070] Step S1, preset parameters

[0071] Start the program, and input the basic parameters and variable parameters into the PLC controller 1. Among them, the variable parameters are planting distance x and fertilization amount y per mu.

[0072] Step S2, real-time measurement of ground wheel speed

[0073] During the running of the seeder, the encoder 11 measures the rotation speed of the ground wheel of the seeder in real time, and transmits the acquired data to the PLC controller 1 . PLC controller 1 through the formula , the calculation of the value measured by the encoder 11 is converted into the internal data of the PLC controller 1.

[0074] Among them: a is the subdivision of the encoder, x is the planting distance...

Embodiment 3

[0094] Example 3 A method of precisely controlling the single planting distance of a planter

[0095] This embodiment mainly describes the control methods of the first program and the second program in the automatic control program of the seeding control module, and the control methods involved in the fertilization control module and the monitoring and alarm module are the same as those in Embodiment 2, so no more details are given here. The following will be explained in conjunction with the specific planting distance:

[0096] Start the first program of the automatic control program in the seeding control module, and set the sowing distance between plants in the first program to be 250mm, and the number of sowing times is 0; at this time, the sowing distance between plants and the number of sowing times in the second program are not all set; Then the first program calculates the internal data to obtain the required number of rotations of the first stepper motor 3; finally th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com