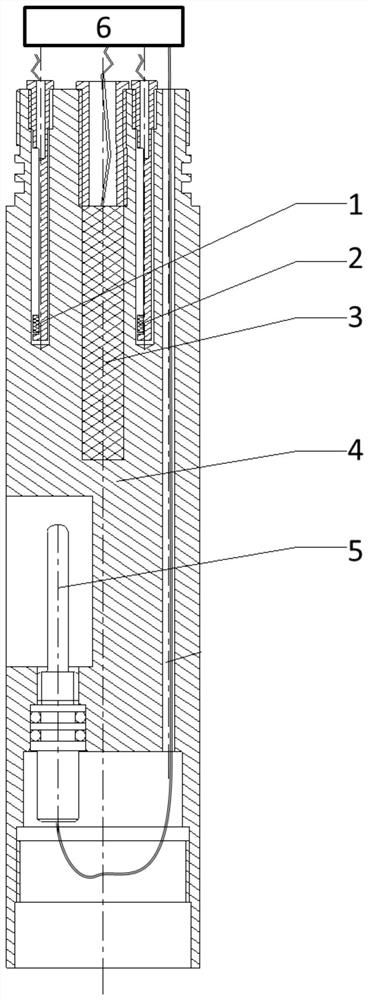

Underground full-borehole thermal type flow measuring device

A thermal flow, measuring device technology, applied in measuring device, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve the problem that thermal flowmeter cannot measure flow accurately, and achieve the effect of improving the measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

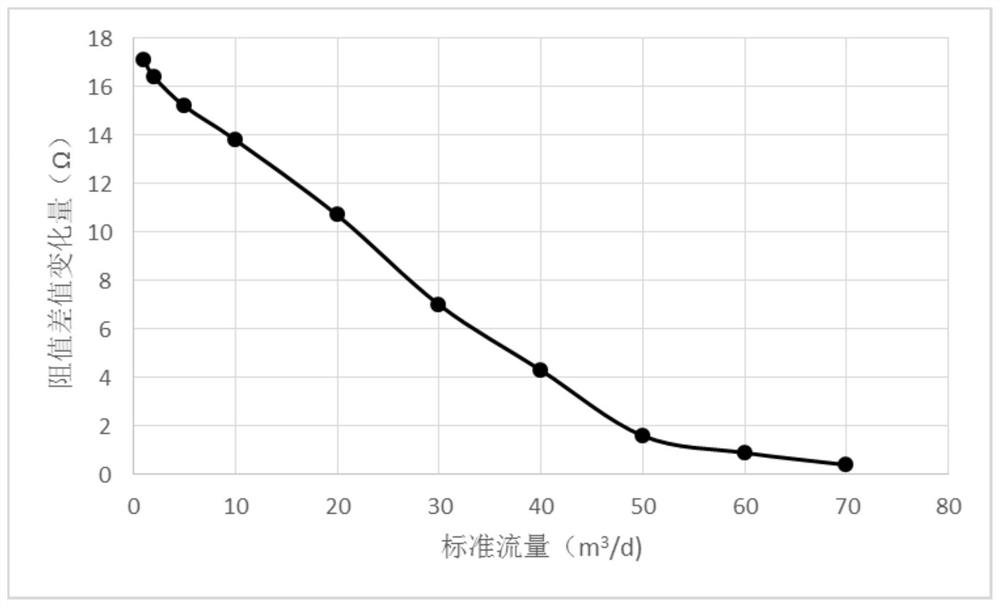

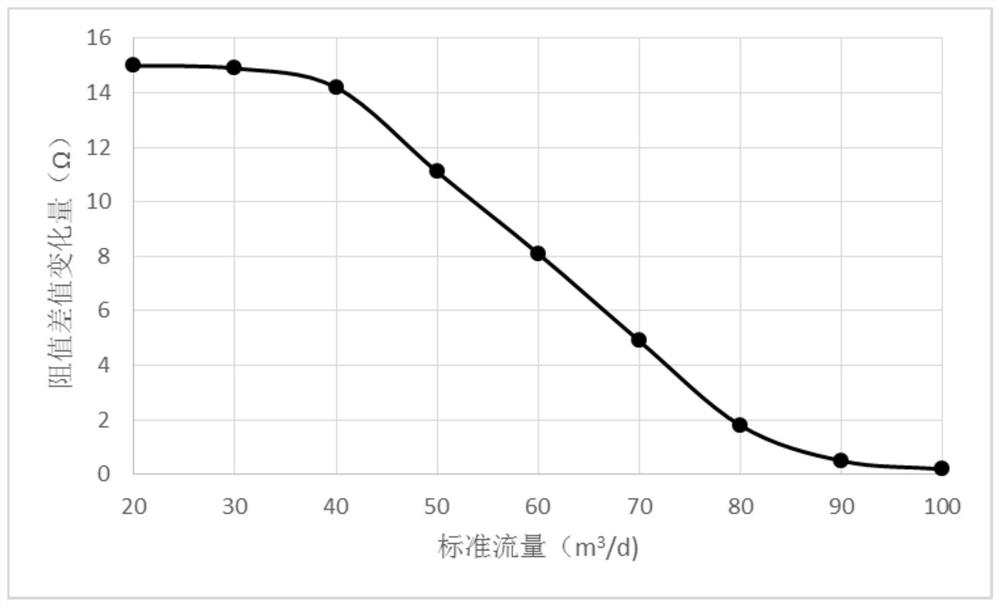

[0020] The specific temperature measurement principle of the technical solution provided by the present invention: when the downhole full-bore thermal flow measurement device is working, the electric heater 3 with constant power heats the body 4 to increase its temperature. The body 4 as an intermediate heat transfer medium exchanges heat with the measured fluid in contact with it, and achieves thermal balance; records the measured value of the measured temperature sensor after the thermal balance, and converts and converts the power supply device 6 to obtain the corresponding flow value at the moment. In this way, the method in which the heater 3 heats the intermediate heat transfer medium, and then conducts it to the measured fluid through the intermediate heat transfer medium, compared with the method of directly placing the heater 3 and the temperature sensor in the fluid in the traditional thermal flowmeter, the temperature caused by the change of the flow rate is more accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com