A support assembly and test method for similar simulation tests of high-speed rotors

A technology similar to analog and high-speed rotors, applied in engine testing, machine/structural component testing, instruments, etc., can solve problems such as low stiffness adjustment accuracy, easy up and down fluctuations, and limited control accuracy of hydraulic devices, etc., to achieve weakened adjustment Error, Stiffness Stability, Effect of Improving Bearing Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0056] A liquid rocket engine high-speed turbo pump rotor with a journal size of 40mm and a length of 300mm, a working speed of 80,000rpm, and a combined support stiffness of the support components of 3x10 7 N / m.

[0057] Since the existing rotor test capability cannot reach the speed of 80000rpm, it is impossible to test and verify the dynamic characteristics of the rotor structure in real operation. Therefore, the similar design method is adopted, and the rotor working rotor is reduced by establishing a similar model.

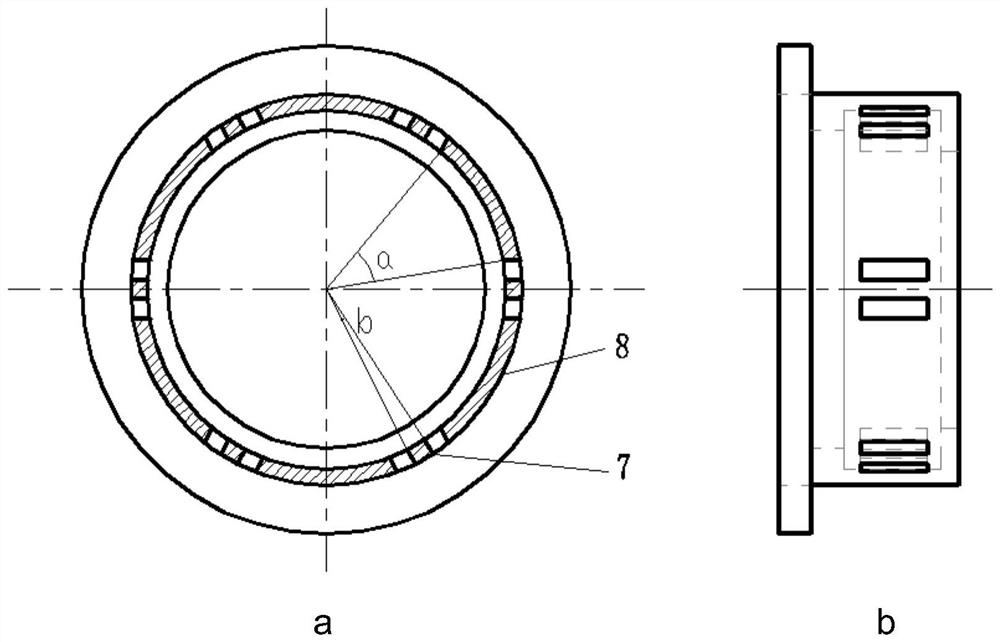

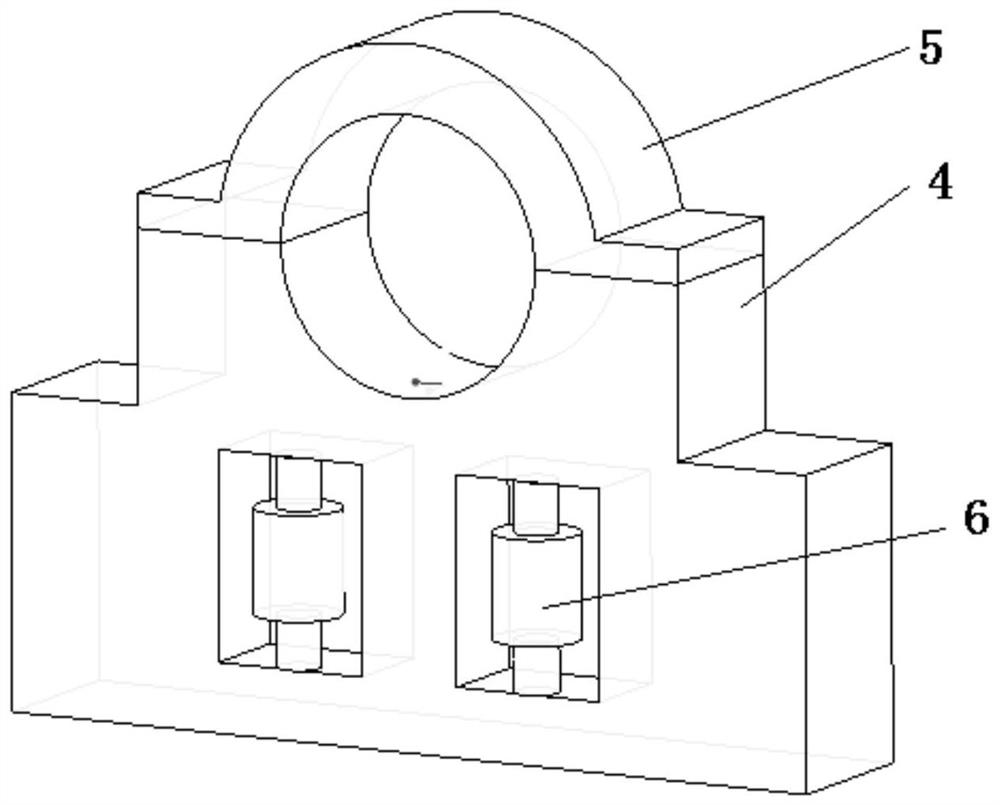

[0058] If it is necessary to reduce the test speed to 40000rpm, according to the similar proportional relationship, both the journal and the length of the rotor need to be doubled, and the support stiffness should also be doubled, that is, to reach 6x10 7 N / m. Since the overall series stiffness of the combined support is less than the stiffness of each single piece, the squirrel cage and support with higher stiffness are selected for combination, and two pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com