Workshop ventilation system

A technology for ventilation systems and workshops, applied in ventilation systems, space heating and ventilation, space heating and ventilation details, etc., can solve problems such as failure to meet hygienic requirements, achieve improved working environment, novel design, and improved ventilation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

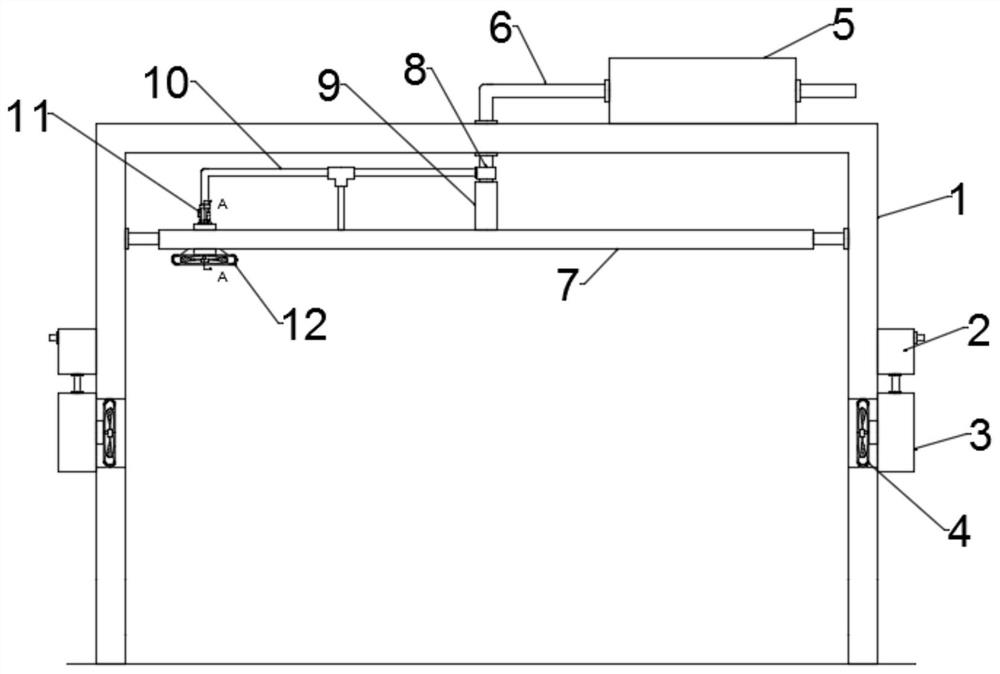

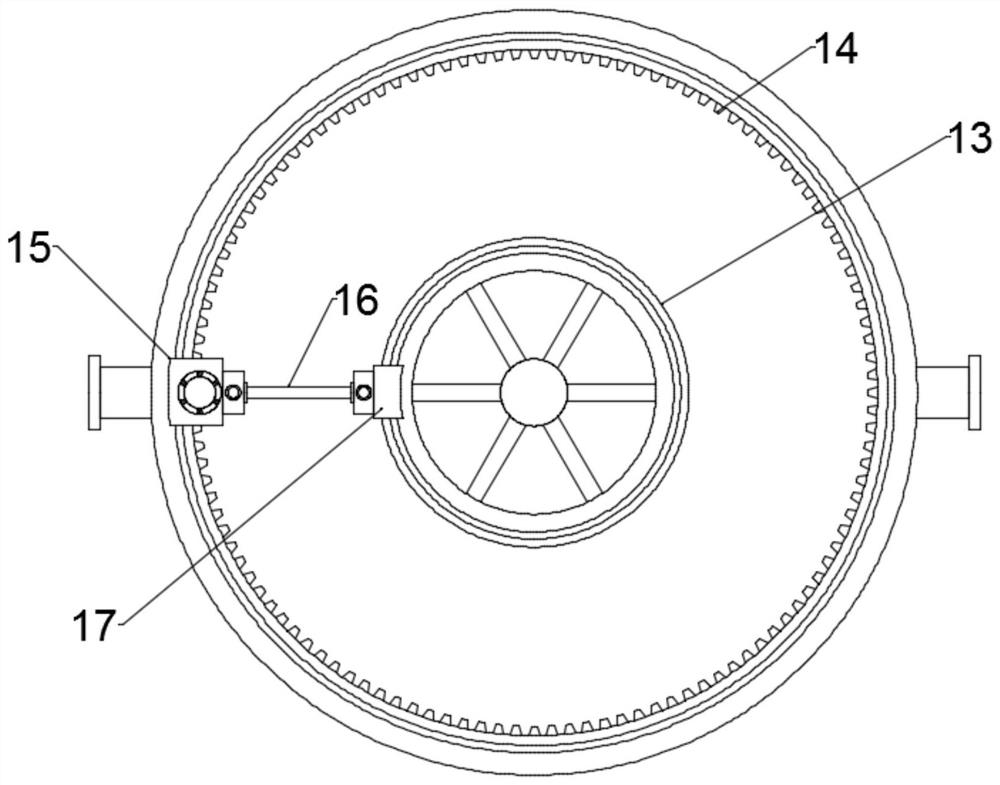

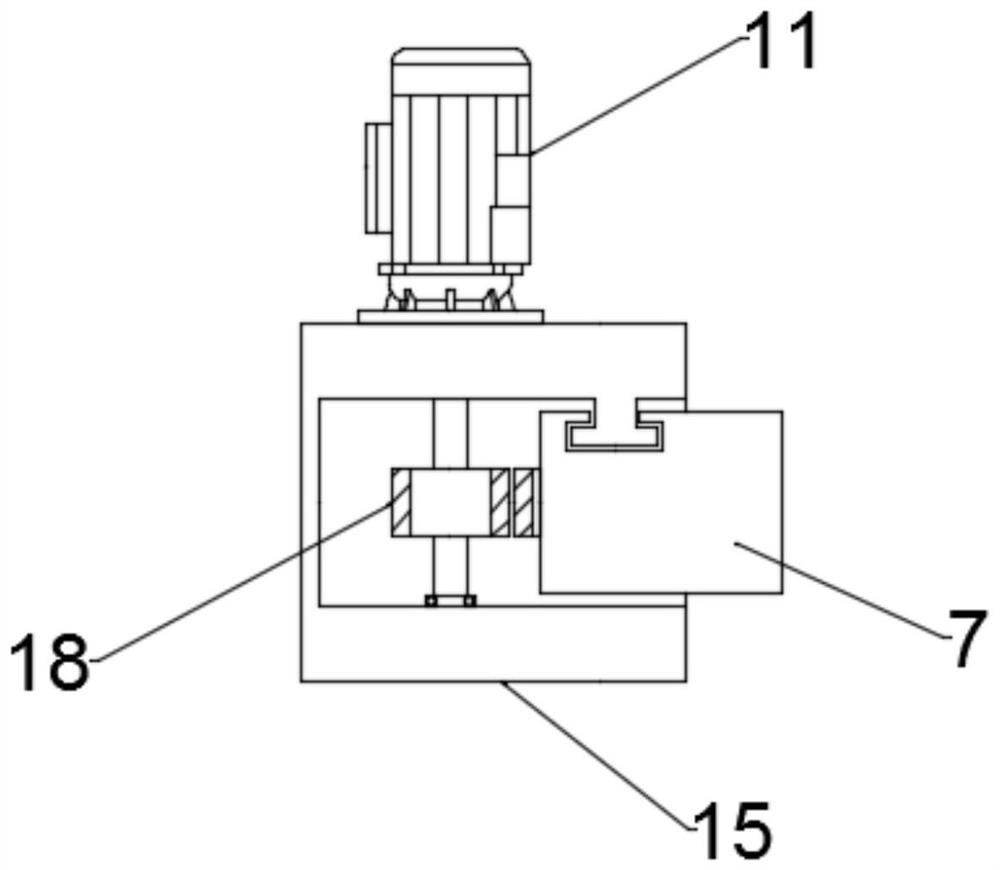

[0025] see Figure 1~4 , in an embodiment of the present invention, a ventilation system for a workshop, including at least one air intake assembly arranged at the side end of the wall body 1 and an air suction assembly arranged between the walls; two groups of the air suction assembly are provided, and Installed on the first sliding seat 15 slidingly connected with the first annular support 7 and the second sliding seat 17 slidingly connected with the second annular support 13, the first sliding seat 15 is fixedly connected with the second sliding seat 17 through the connecting rod 16 , the first sliding seat 15 is arranged in a U-shaped structure, its upper end is provided with a motor 11, the output shaft of the motor 11 is fixedly connected with the gear 18 arranged inside the first sliding seat 15, and the gear 18 is connected with the first ring bracket 7. The inner ring teeth 14 on the inner wall are meshed. When the motor 11 is working, the air suction assembly follows...

Embodiment 2

[0033] see Figure 1~4 , in an embodiment of the present invention, a ventilation system for a workshop, including at least one air intake assembly arranged at the side end of the wall body 1 and an air suction assembly arranged between the walls; two groups of the air suction assembly are provided, and Installed on the first sliding seat 15 slidingly connected with the first annular support 7 and the second sliding seat 17 slidingly connected with the second annular support 13, the first sliding seat 15 is fixedly connected with the second sliding seat 17 through the connecting rod 16 , the first sliding seat 15 is arranged in a U-shaped structure, its upper end is provided with a motor 11, the output shaft of the motor 11 is fixedly connected with the gear 18 arranged inside the first sliding seat 15, and the gear 18 is connected with the first ring bracket 7. The inner ring teeth 14 on the inner wall are meshed. When the motor 11 is working, the air suction assembly follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com