A kind of gearbox-free motor direct drive device and operation control method

A direct-drive, box-type technology, applied in electromechanical devices, measuring devices, and mechanical energy control, etc., can solve the problems of complex ground structure, high one-time investment, and difficult management of pumping units, and achieve low one-time investment and safety. The effect of high coefficient and few transmission links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The following will clearly and completely describe the technical solutions of the embodiments of the present invention with reference to the accompanying drawings of the embodiments of the present invention.

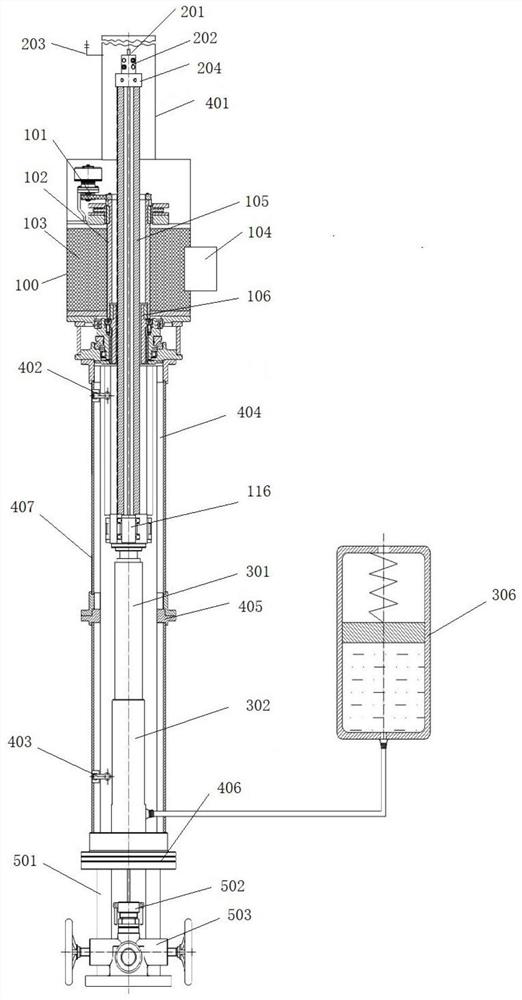

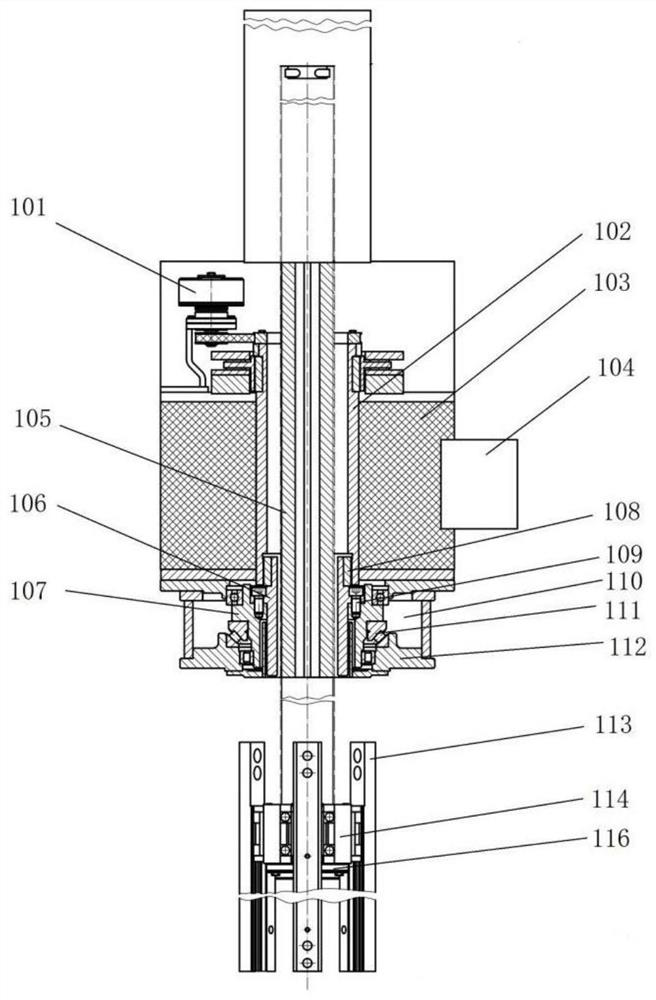

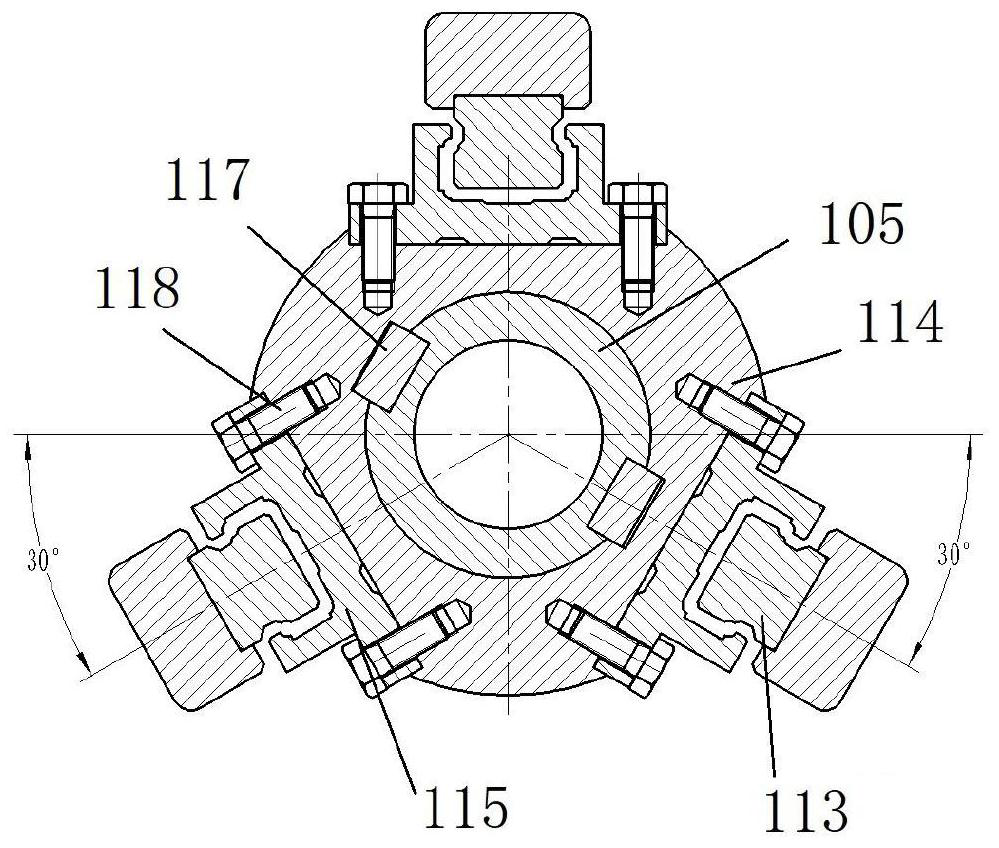

[0061] A gearbox-free motor direct drive device, including: a casing assembly, a transmission component, a load monitoring unit, a hydraulic energy storage unit, and a wellhead matching unit;

[0062] The casing assembly seals the transmission assembly and the load monitoring unit inside;

[0063] A screw 105 and a motor rotor 102 are arranged in the middle of the transmission assembly, and a motor stator 103 is arranged outside the motor rotor 102. The rotational movement of the motor rotor 102 drives the polished rod 201 in the load monitoring unit to reciprocate up and down, converting electric energy into system lifting kinetic energy;

[0064] The load sensor 204 in the load monitoring unit is installed between the square clip 202 and the lead screw 105 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com