Concrete quantitative preparation and uniform mixing device

A concrete and mixing technology, which is applied in the direction of clay preparation device, mixing operation control device, mixing operation control, etc., can solve the problems of high risk factor, large dust, and physical injury of workers, etc., and achieve the effect of high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

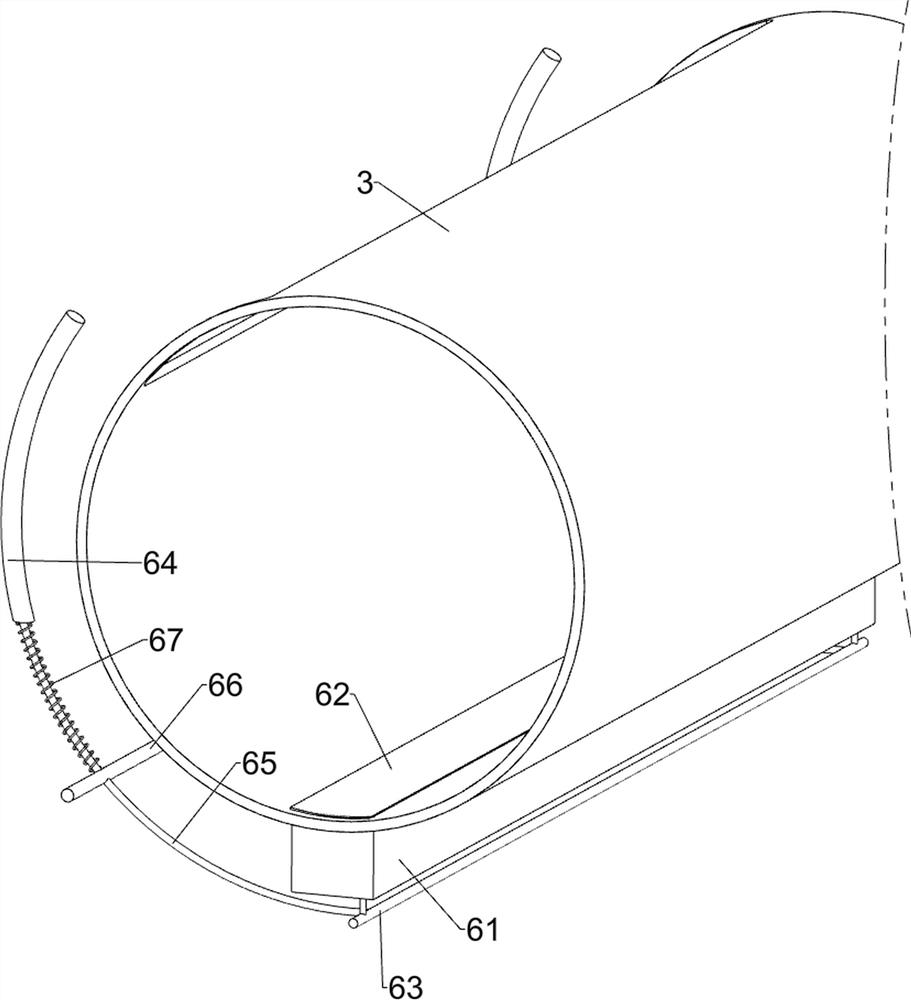

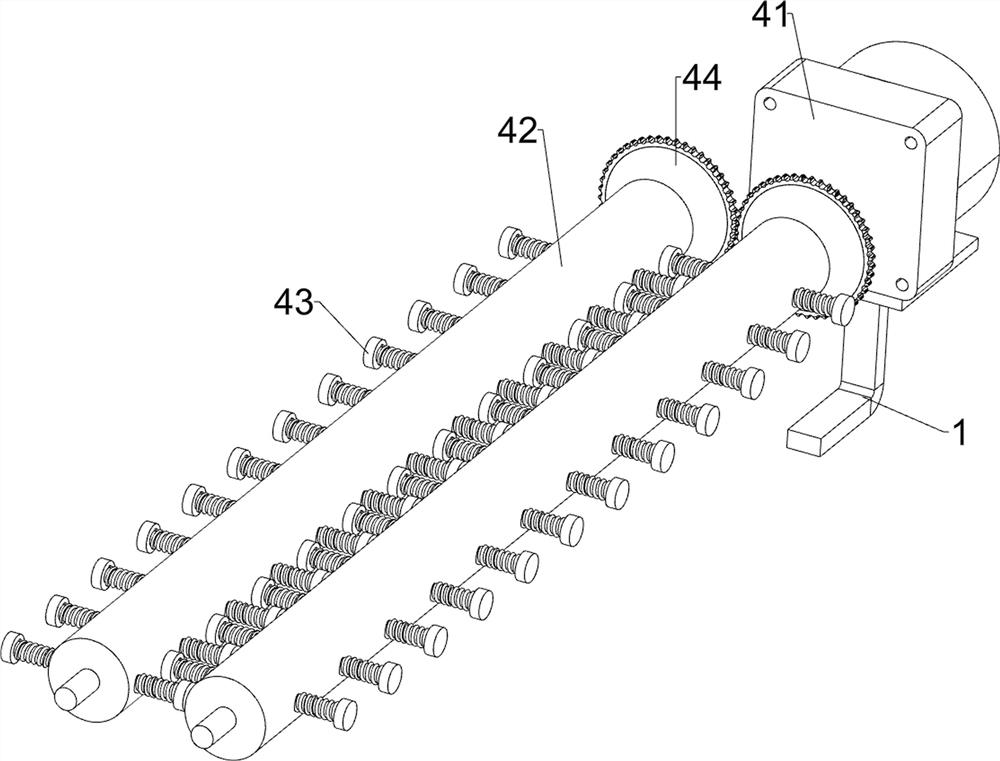

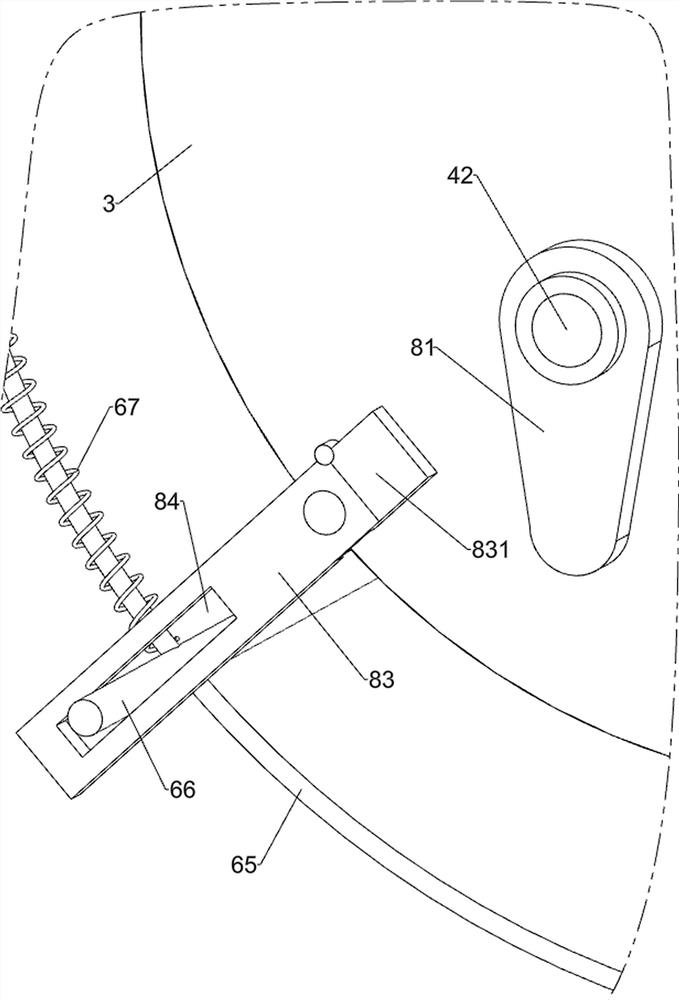

[0025] A concrete quantitative preparation and mixing device, such as Figure 1-5 As shown, it includes a bracket 1, a blanking frame 2, a mixing cylinder 3, a mixing assembly 4, a blanking assembly 5, and a sliding discharge assembly 6. The upper side of the bracket 1 is equipped with a blanking frame 2, and the upper side of the bracket 1 A mixing cylinder 3 is installed on the side, a mixing assembly 4 is installed on the support 1, a blanking assembly 5 is installed on the upper side of the mixing cylinder 3, and a sliding discharge assembly 6 is installed between the mixing cylinder 3 and the blanking frame 2.

[0026] When the concrete is to be quantitatively prepared and mixed, the materials are respectively placed in the blanking frame 2, and then the mixing component 4 is started, and the mixing component 4 will drive the blanking component 5 to operate, so that the materials in the blanking frame 2 fall into the mixing In the cylinder 3, the mixing component 4 mixes ...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , Figure 6 and Figure 7 Shown, also comprise stop blowing assembly 7, stop blowing assembly 7 includes first cylinder body 71, intake pipe 72, first piston rod 73, the 3rd spring 74, second cylinder body 75, connecting pipe 76, Deflation pipe 77, the second piston rod 78, the fourth spring 79 and wedge block 710, the front lower side of the blanking frame body 2 is connected with the first cylinder 71, the first cylinder 71 is connected with the intake pipe 72, the intake pipe 72 is provided with a check valve, the first piston rod 73 is slidably connected in the first cylinder body 71, the third spring 74 is connected between the first piston rod 73 and the first cylinder body 71, and the front of the blanking frame body 2 The lower side of the part is connected with a second cylinder body 75, a connecting pipe 76 is connected between the first cylinder body 71 and the second cylinder body 75, and an air release pipe 77 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com