Solid CO2 cleaning and spraying device

A CO2 and nozzle cleaning technology, which is applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of time-consuming and labor-intensive users, easy to suffer from cold and fatigue, and large recoil, so as to improve convenience, reduce the impact of recoil, and improve comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

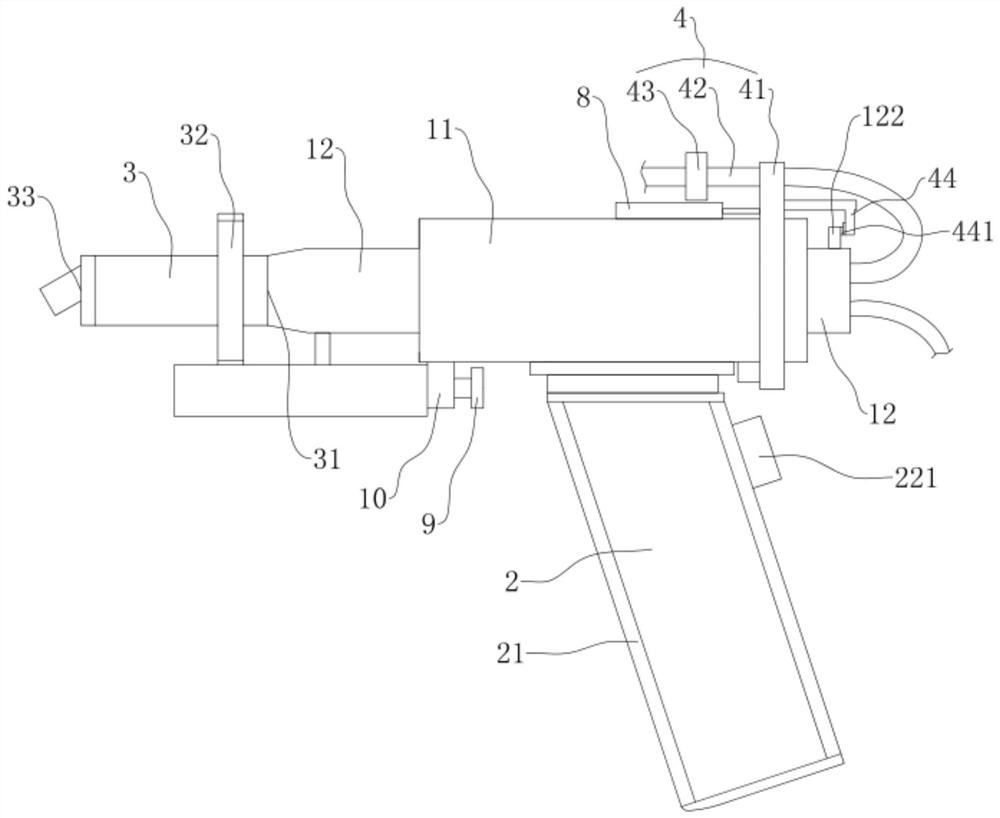

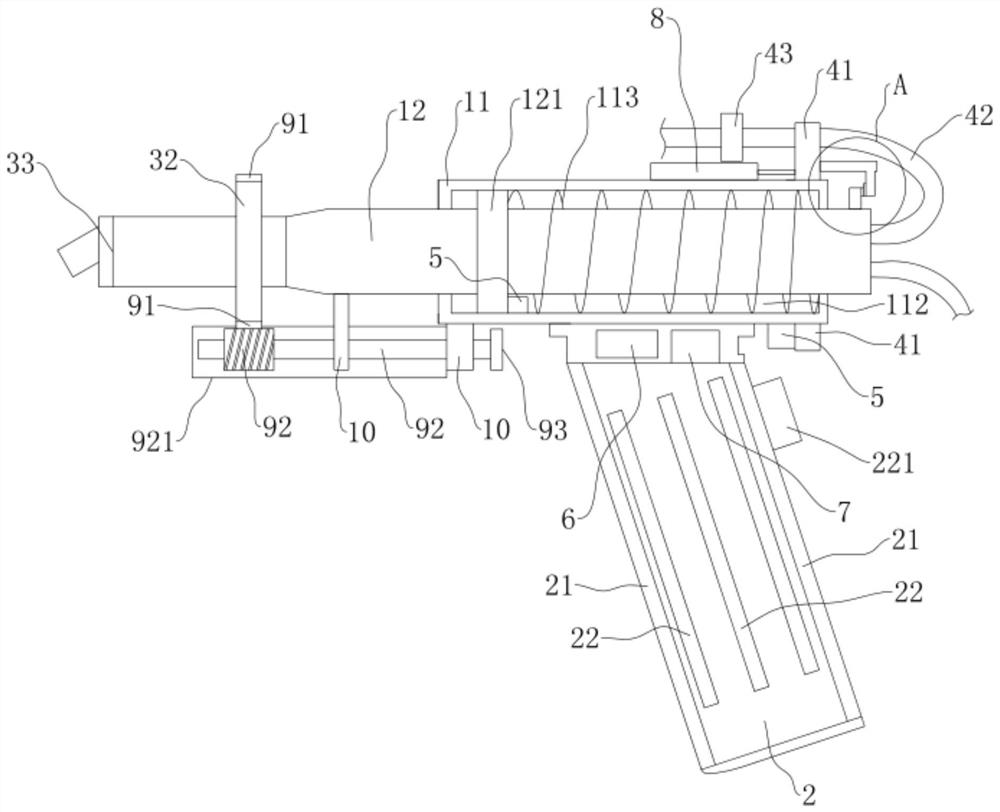

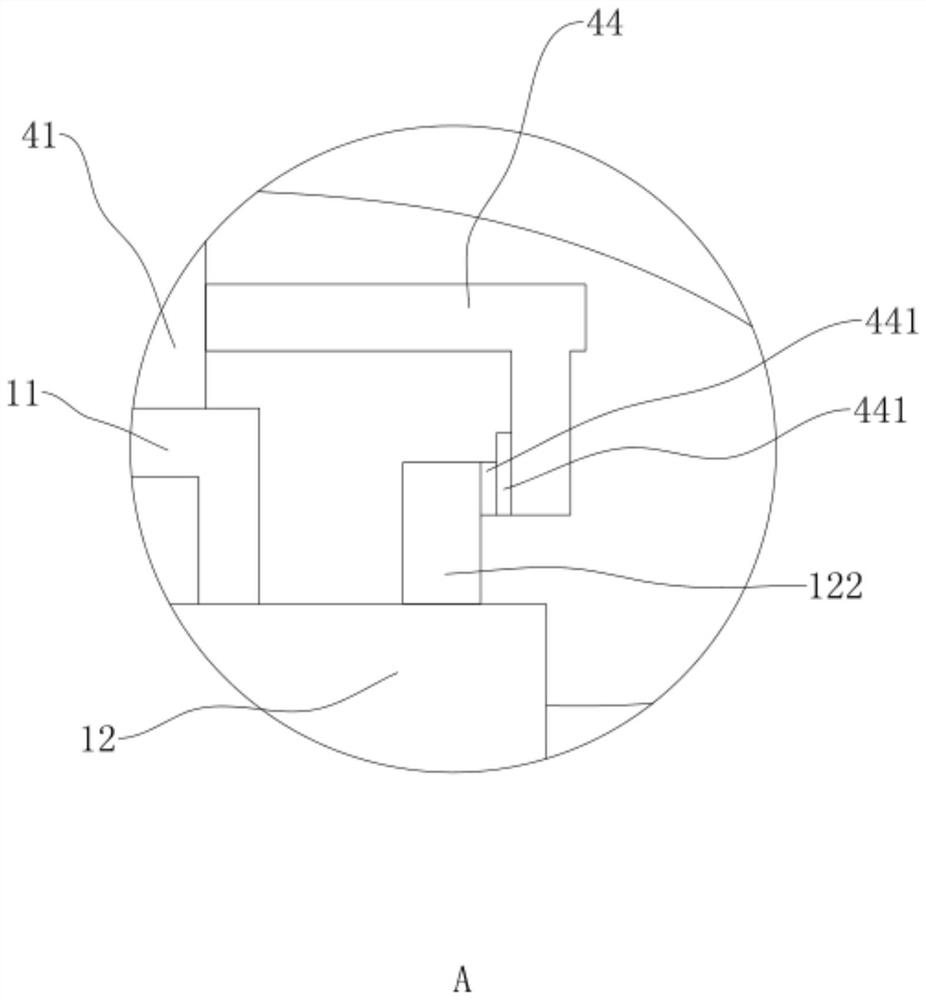

[0029] refer to Figure 1 to Figure 4 For solid CO 2 Cleaning the nozzle unit is further explained.

[0030] a solid CO 2 Clean the spray head unit, such as figure 1 As shown, it includes a gun barrel 1 and a gun handle 2 connected to the gun barrel 1. One end of the gun barrel 1 is provided with a nozzle 3, and the nozzle 3 is provided with an air ice inlet 31 communicating with the inside of the gun barrel 1, and the dry ice is passed through a pneumatic Push it into the air ice inlet 31, so as to enter the spray head 3 and spray out through the gun barrel 1, so as to be used for cleaning.

[0031] Such as figure 1 As shown, the gun barrel 1 includes a connecting pipe 11 connected to the gun handle 2 and a nozzle pipe 12 passing through the connecting pipe 11. One end of the nozzle pipe 12 is connected and communicated with the spray head 3, and the connecting pipe 11 is provided with a buffer injection pipe. An elastic member 113 for spraying force, and the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com