Motor drive fault emergency device

A technology of motor drive and emergency device, applied in the direction of electromechanical devices, electric components, connection with control/drive circuits, etc., can solve problems such as motor drive damage, work process interference, and impact on machine service life, and achieve the effect of avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

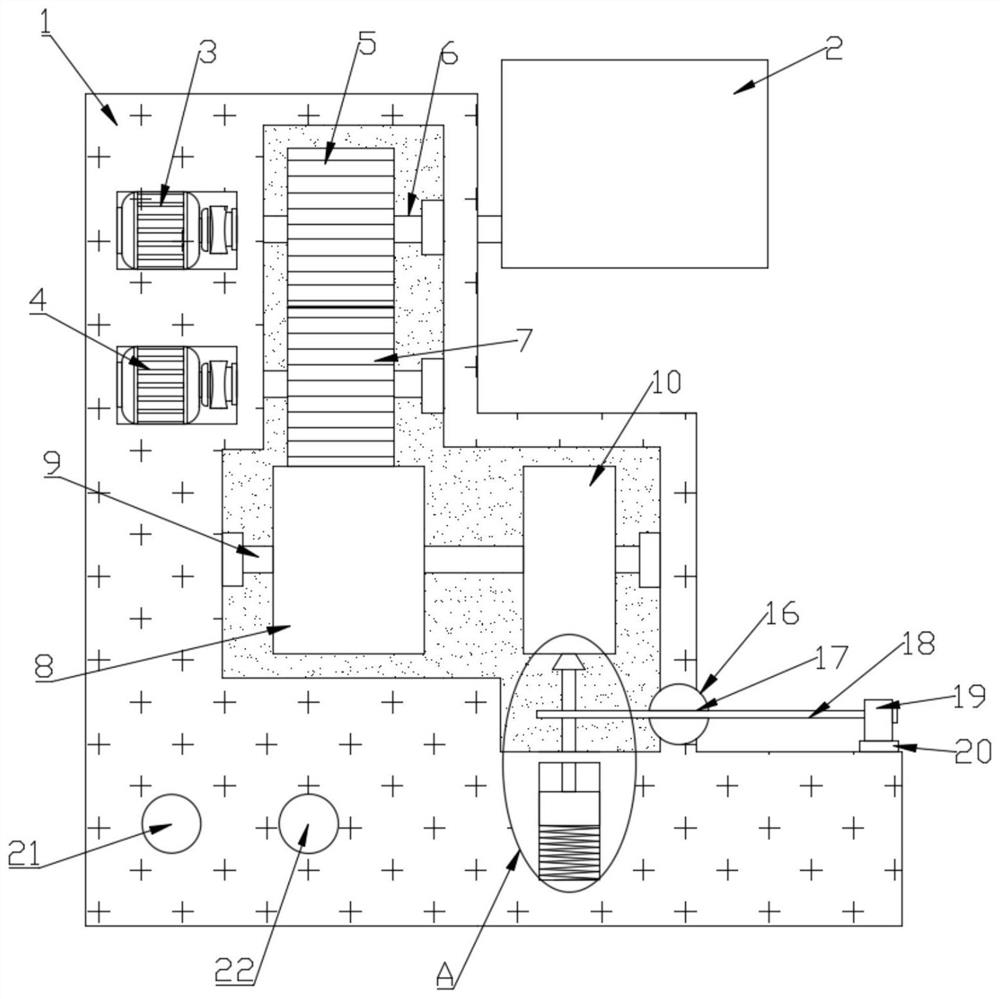

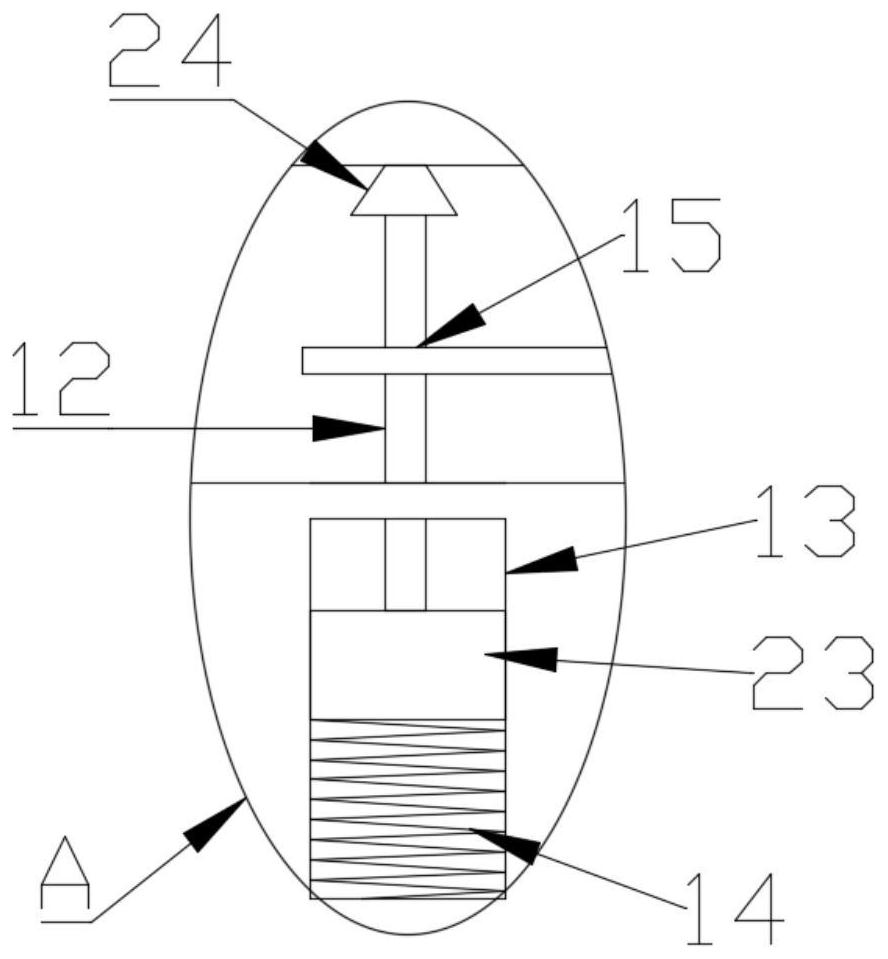

[0024] see Figure 1-4 , the present embodiment provides a motor-driven failure emergency device, including a device housing 1 and a drive motor 3 fixedly installed inside the device housing 1, and a No. 1 rotating shaft 6 is fixedly installed on the output shaft of the drive motor 3, so The other end of the No. 1 rotating shaft 6 is connected with a machine 2, and a failure emergency mechanism acting on the drive motor 3 is installed in the device housing 1;

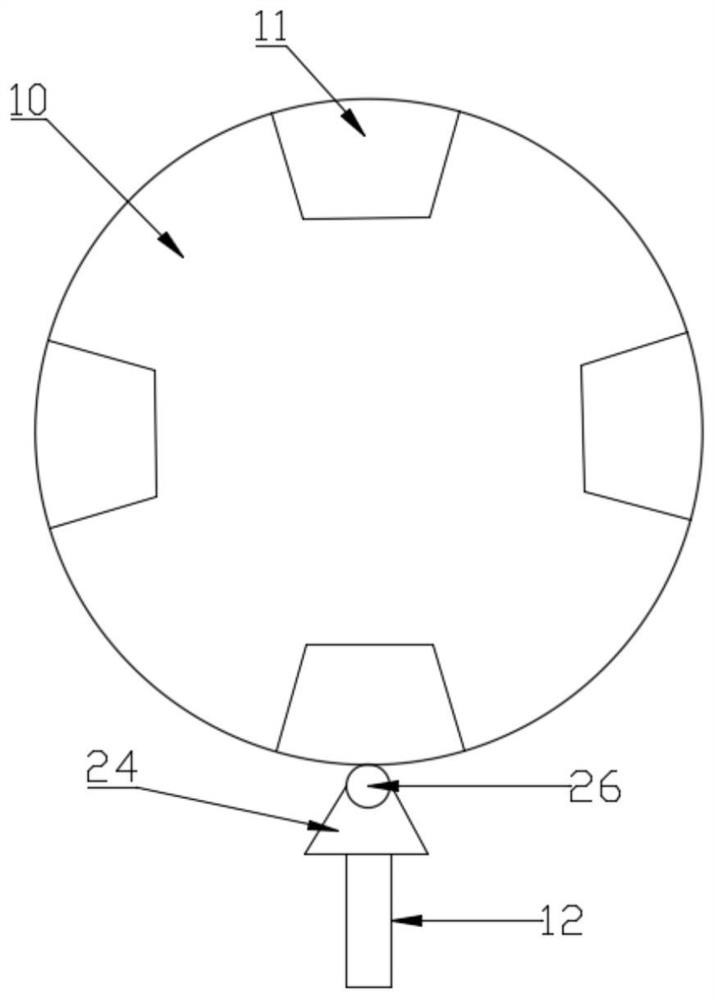

[0025] The failure emergency mechanism includes a No. 1 gear 5, an emergency motor 4, a No. 2 rotating shaft 9 and a control mechanism. The No. 1 gear 5 is fixedly installed on the No. 1 rotating shaft 6, and the emergency motor 4 is fixedly installed on the device housing 1 The inside and the output shaft of the emergency motor 4 are fixedly installed with the No. 2 gear 7 meshing with the No. 1 gear 5. The No. 2 rotating shaft 9 is rotatably installed in the inside of the device housing 1 and the No. 2 rotating shaft ...

Embodiment 2

[0035] When the rotating disk 10 rotates, it will constantly rub against the control assembly 24. After a long period of use, the rotating disk 10 and the control assembly 24 will cause the device to malfunction due to wear and tear. In order to solve this problem, this embodiment is based on the first embodiment A further improvement on the above, the improvement is: the top of the control assembly 24 is rotatably installed with a roller 26, so that the sliding friction between the rotating disk 10 and the control assembly 24 can be converted into friction between the roller 26 and the rotating disk 10 Rolling friction, thereby greatly reducing the wear of the rotating disk 10 and the control assembly 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com