Full-automatic injection tube detection machine

A technology of injection tube and detection machine, which is applied in the field of injection tube detection, can solve the problems of increased resistance of injection tube movement, dead angle of visual detection, and influence of visual detection, etc., and achieves the effects of improving stability, fast detection speed, and improving delivery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

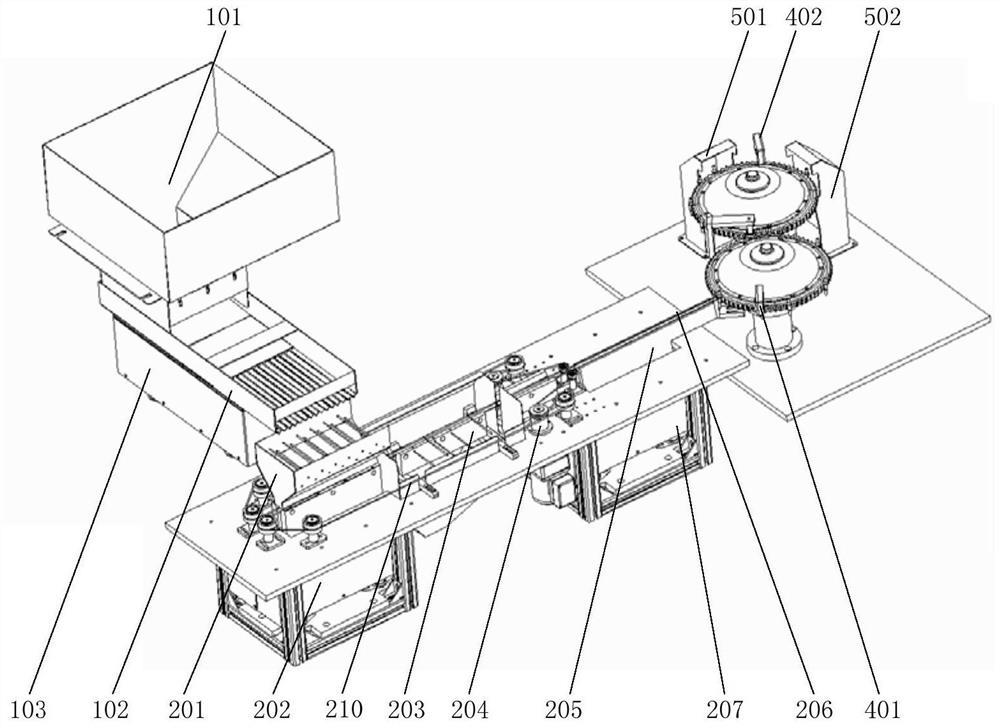

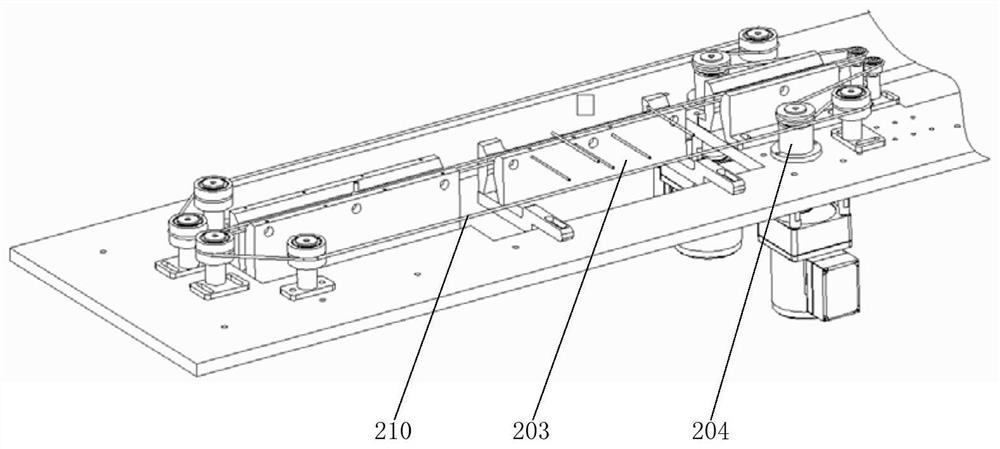

[0051] The structure specification is attached below Figure 1-7 The specific technical solutions of the present invention are further described.

[0052] as attached figure 1 As shown, the embodiment of the present invention provides a fully automatic syringe inspection machine, including: a feeding device, a conveying device, a suction turntable device, a detection device and a sorting device.

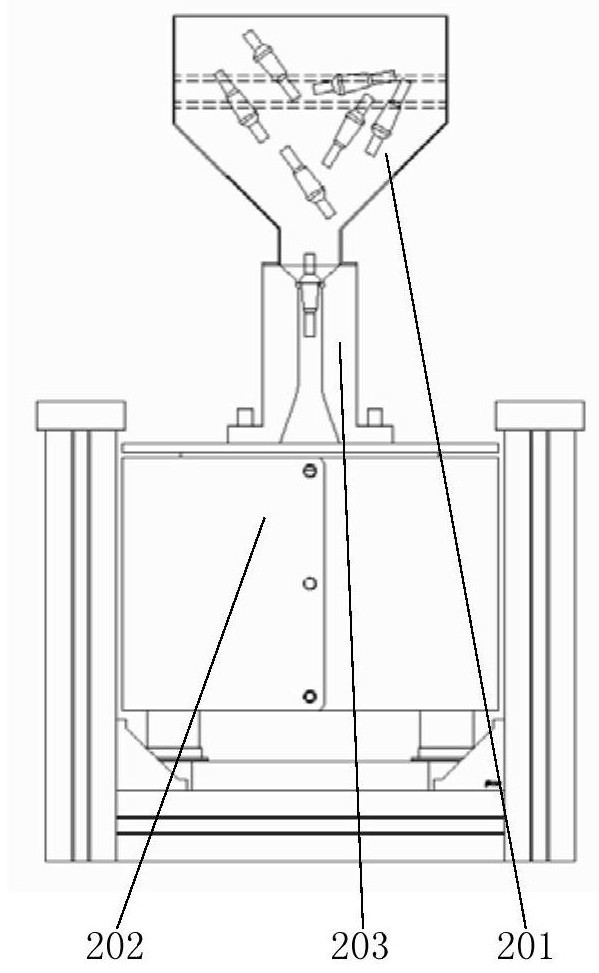

[0053] The feeding device includes a main bin 101 , a buffer bin 102 and a feeding linear vibrator 103 .

[0054] The main material box 101 is a funnel-shaped container, the bottom of which is connected to the buffer material box 102; the connection between the main material box 101 and the buffer material box 102 is provided with an adjusting plate for adjusting the discharge flow. The buffer material box 102 is a rectangular tank box, the top of one end of the buffer material box 102 is connected with the bottom of the main material box 101, the other end side is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com