Automatic loading rod assembling device for SHPB test

A technology for automatic assembly and loading of rods, which is applied to measuring devices, instruments, scientific instruments, etc., and can solve problems such as long-term operation of unfavorable equipment and shortened cylinder life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

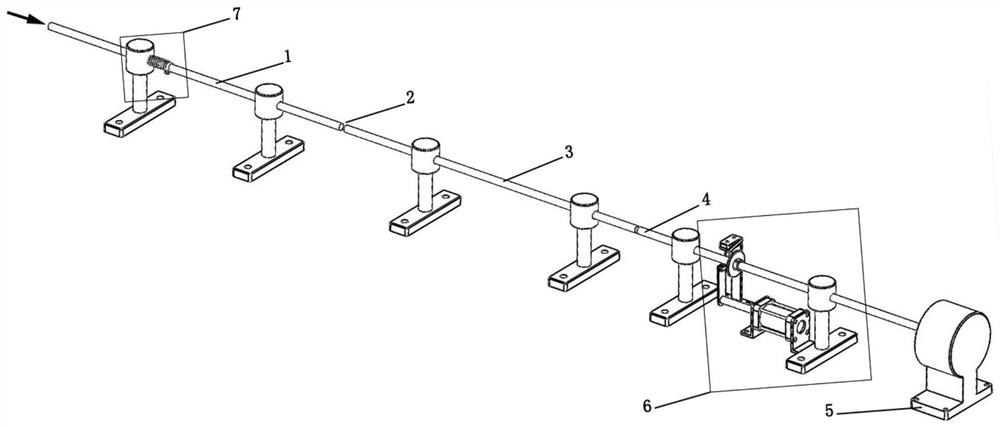

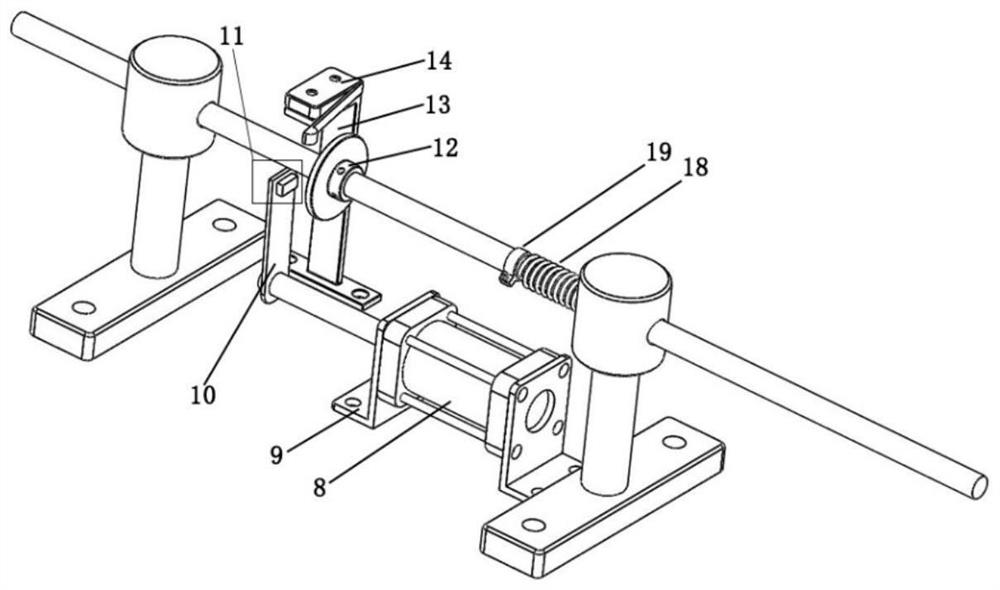

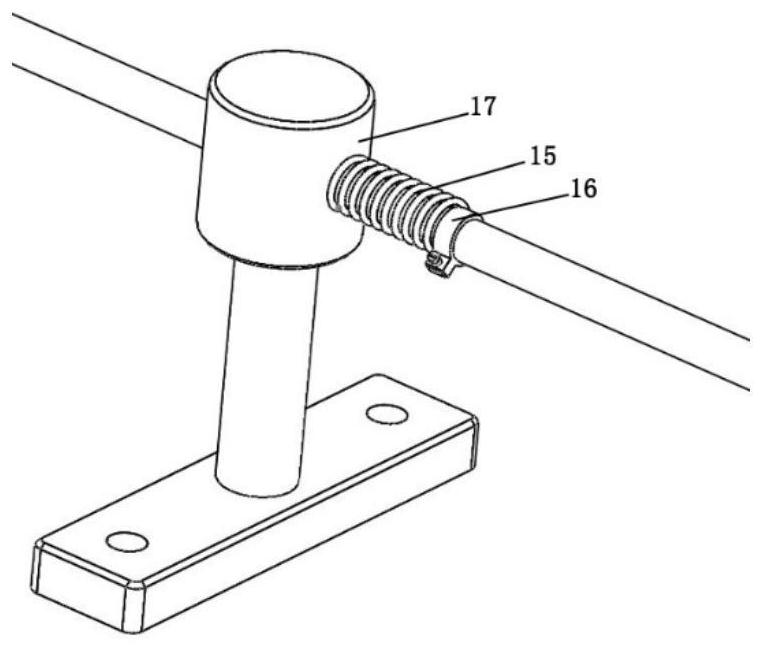

[0046] The diameter of the loading rod described in this embodiment is 16 mm, the lengths of the incident rod 1, the transmission rod 3 and the absorption rod 4 are all 1000 mm, and the loading rod is fixed on the operating platform with a T-shaped installation groove through the loading rod bracket 17 Above, the axis of the loading rod is 150mm away from the console. Use the SC50-100 type air cylinder, install it directly below the absorption rod through the pneumatic push rod bracket 9, the stroke of the pneumatic push rod 8 is 100mm, the diameter is 16mm, and the front end is provided with threads.

[0047] The traction piece 10 is a Q235 steel sheet of 3mm×25mm×100mm, one end has a Φ16mm through hole, and is fixed on the front end of the pneumatic push rod 8 through a nut, and the other end is provided with an M4 threaded hole. The NdFeB permanent magnets 23 with through holes are connected.

[0048] The traction flange 12 is a Q235 steel ring with an outer diameter of 40...

Embodiment 2

[0058] In this embodiment, a rod system with a diameter of 16 mm is used. The lengths of the incident rod 1, the transmission rod 3 and the absorption rod 4 are all 1000 mm. The loading rod is fixed on the console with a T-shaped mounting groove through the loading rod bracket 17. 150mm from the operating platform. Pneumatic push rod 8 uses SC50-100 type air cylinder, and is installed directly below the absorption rod through pneumatic push rod bracket 9. Pneumatic push rod 8 has a stroke of 100mm, a diameter of 16mm, and a thread at the front end.

[0059] The traction piece 10 is a Q235 steel sheet of 3mm×25mm×100mm, one end has a Φ16mm through hole, and is fixed on the front end of the pneumatic push rod through a nut; the other end of the traction piece 10 is provided with a Φ3mm through hole, and the M3 inner hexagon magnetic adjustment bolt passes The through hole is connected with the permanent magnet 23 in the magnetic force size adjusting member 11; the attraction for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com