Finished product detection device for motor shaft machining

A technology for finished product inspection and motor shaft, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of end face runout detection of motor shafts, affecting the connection between the driving shaft and the driven shaft, etc., so as to improve efficiency and promote Effect of synchronicity, reduced time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

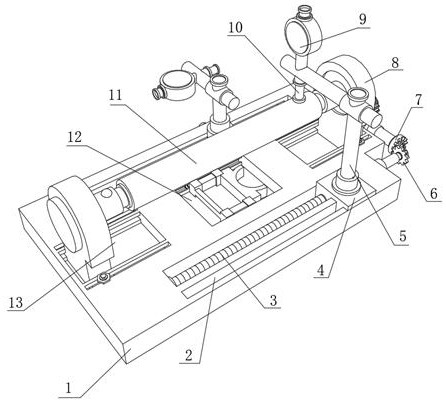

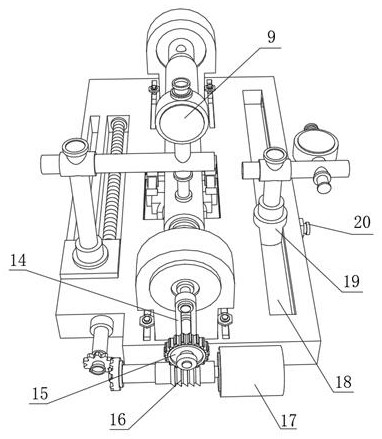

[0033] A finished product detection device for motor shaft processing, such as Figure 1-5As shown, it includes a base 1, the top outer wall of the base 1 is provided with two chute 13, and the two chute 13 are slidably connected with a fixed seat 8, and the top of the base 1 is close to the top outer walls on both sides of the two chute 13 A first fixing hole 22 is opened, and each first fixing hole 22 is slidably connected with a second fastening bolt. The middle outer wall of the top of the base 1 is provided with an installation groove 12, and the installation groove 12 is provided with a support mechanism 24. The opposite sides of the two fixing bases 8 are provided with a clamping mechanism, and the opposite sides of the two clamping mechanisms are clamped with the same motor shaft 11 , and the outer wall of the top side of the base 1 is provided with a fixing groove, and the fixing groove is formed. The inner walls on both sides are connected with the same screw 3 throu...

Embodiment 2

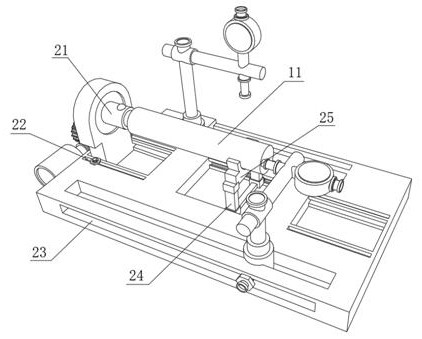

[0038] A finished product detection device for motor shaft processing, such as Figure 4-5 As shown, in order to solve the problem of installation and support of the motor shaft 11; this embodiment makes the following improvements on the basis of Embodiment 1: the support mechanism 24 includes a semicircular support plate 25, a frosted plate 26, and two limit rolling grooves 27 , two rollers 28 and two telescopic rods 29, and the two limit rolling grooves 27 are respectively opened on the inner walls of both sides of the installation groove 12, and the two rollers 28 are slidably connected to the two limit rolling grooves 27. The two ends of the plate 26 are respectively fixed on the opposite sides of the two rollers 28 by connecting blocks, the two telescopic rods 29 are respectively welded to the top outer wall of the frosted plate 26, and the semicircular support plate 25 is welded to the extension rod ends of the two telescopic rods 29. The inner ring of the semicircular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com