Novel grooving machine facilitating deep hole operation

A slotting machine, a new type of technology, applied in the direction of earthwork drilling, drilling equipment, directional drilling, etc., can solve the problems of unstable transmission, repeated soil transfer, high construction cost, etc., to avoid equipment shaking, eliminate transmission arm, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

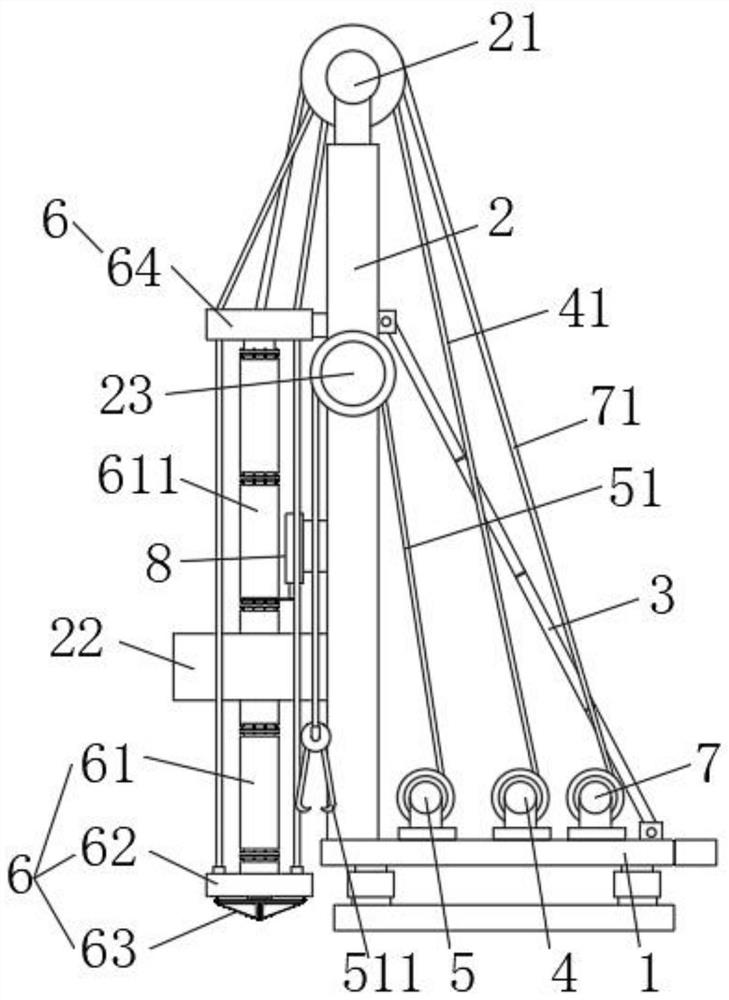

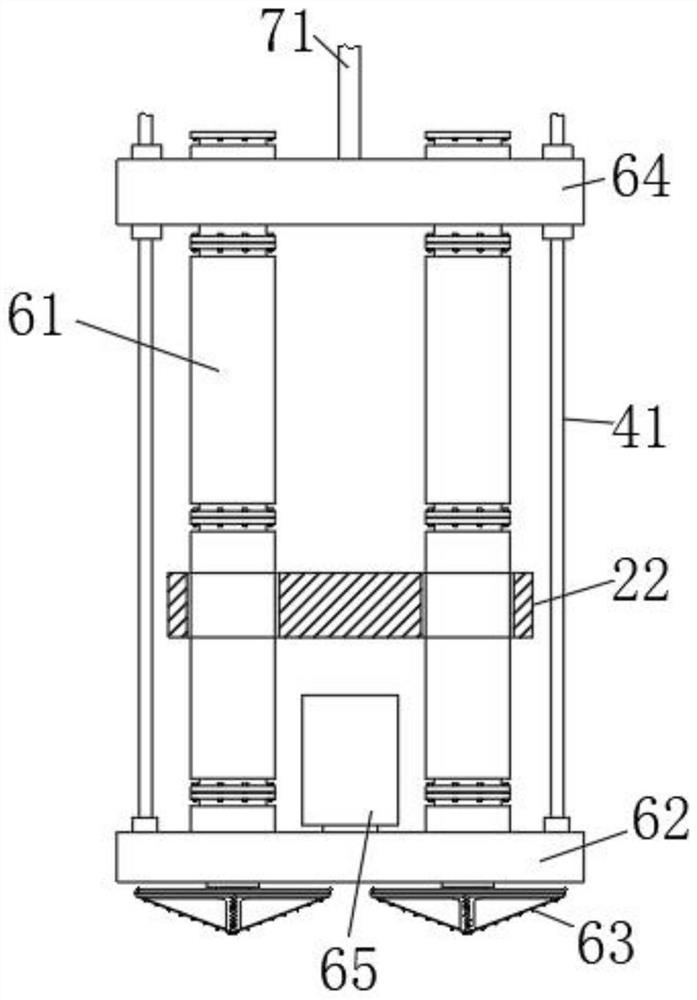

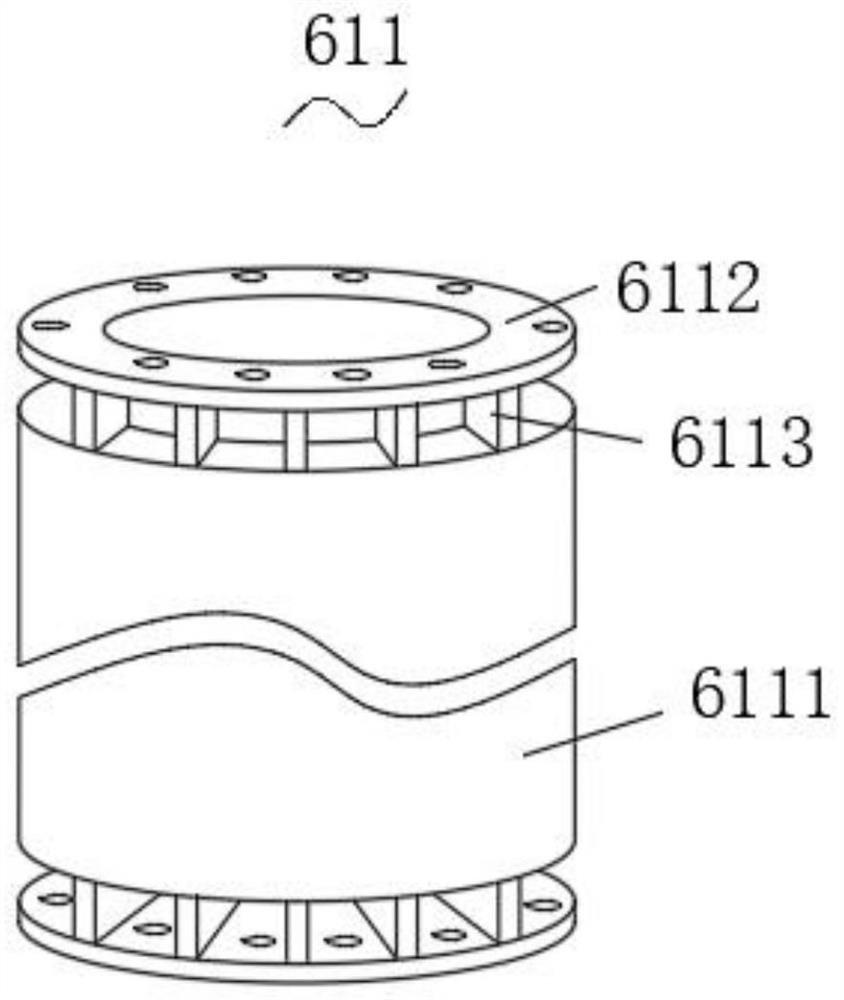

[0030] like Figure 1-Figure 4 As shown, a new slotting machine that is convenient for deep hole operation includes a machine base 1, and a column 2 is vertically arranged on the side of the surface of the machine base 1, and a diagonal bar 3 is passed between the column 2 and the machine base 1. Connected, the bottom end of the outer wall of the column 2 is vertically provided with a guide seat 22, and the inside of the guide seat 22 slides through the drilling mechanism 6; the guide seat can constrain and position the drilling mechanism from the outside of the bottom to avoid the drilling mechanism from shaking. Guarante...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com