Concrete-filled steel tube optimized structure adopted in vertical structure and steel tube support mounting method

A technology of steel pipe concrete and vertical structures, which is applied in the direction of pillars, building structures, columns, etc. It can solve the problems of high construction difficulty coefficient, non-perpendicular structure and ground, and overall column overturning, so as to reduce the difficulty and site Easier control of demand, quality, and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

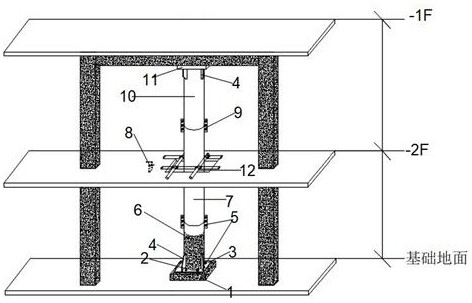

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0034] The invention provides an optimized structure of steel pipe concrete in a vertical structure and a steel pipe support installation method to ensure that after the basement bent frame is removed, the ground load will not cause damage to the poured basement beams, thereby ensuring the safety of the basement main project and improving The quality of construction in the basement.

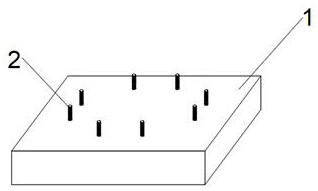

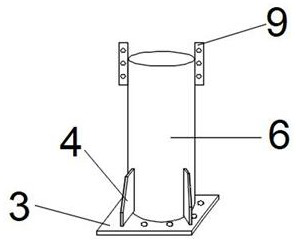

[0035] As an embodiment of the present invention, the application provides such as Figure 1-5 In the vertical structure shown, steel pipe concrete is used to improve structural force transmission. It mainly consists of concrete cushion 1, ground anchor bolt 2, steel pipe column lower support end plate 3, lateral support stiffener 4, hex nut 5, lower The supporting steel pipe column 6, the middle supporting steel pipe column 7, the embedded lifting ring 8, the lug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com