Drum-type chemical fiber rag ultrasonic hot cutting equipment

An ultrasonic and drum-type technology, which is applied in the field of drum-type chemical fiber rag ultrasonic hot cutting equipment, can solve the problems of scattered cloth output, cloth tearing, and wrinkling of the incision, so as to improve production efficiency, improve product quality, and smooth the cut. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A drum-type chemical fiber rag ultrasonic hot cutting equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

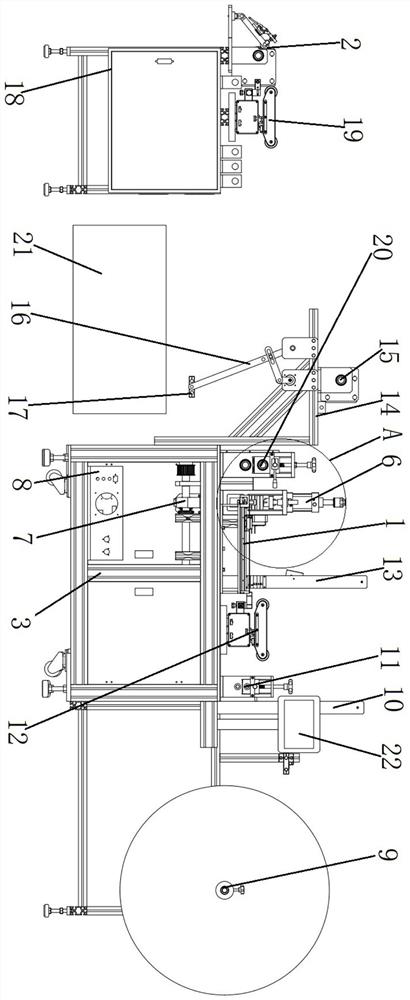

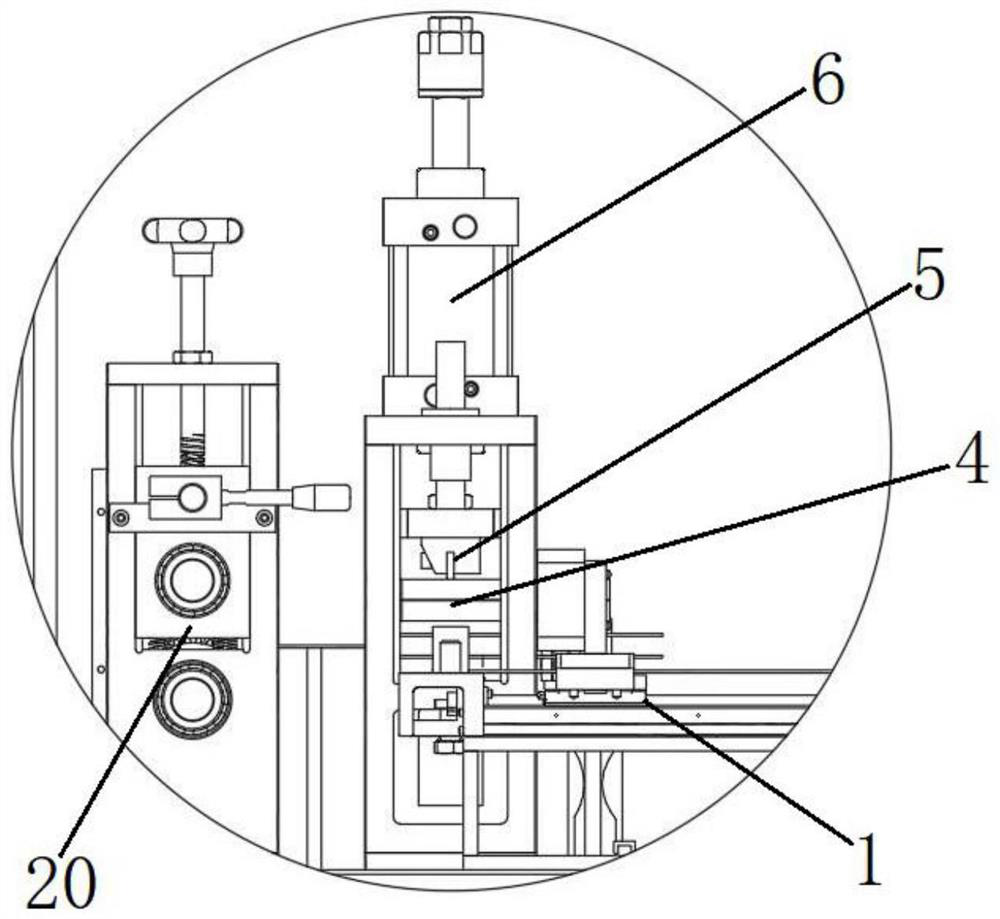

[0012] combined with Figure 1-2 , a drum-type chemical fiber rag ultrasonic hot cutting equipment, including a feeding device, a cloth feeding device 1, an ultrasonic hot cutting device, a cloth arrangement device, and a rolling device 2, the feeding device, a cloth feeding device 1, an ultrasonic hot cutting device, a The cloth device and the coiling device 2 are arranged sequentially according to the order of material entry and exit; the ultrasonic hot cutting device includes a counter 3, an ultrasonic welding plate 4 arranged on the counter 3, a knife mold 5 located above the ultrasonic welding plate 4, and a The cylinder 6 above the die 5 is fixedly connected with a die frame above the counter 3, the cylinder body of the cylinder 6 is connected with the die frame, the rod body of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com