Electronic luggage leather cutting device with scrap collecting function

A cutting device and functional technology, applied in the field of electronic luggage leather cutting device, can solve the problems of waste of manpower, increased difficulty of collection and cleaning, etc., and achieve the effect of convenient centralized discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

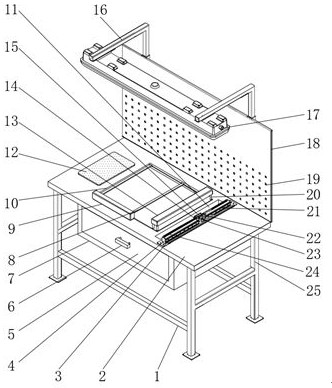

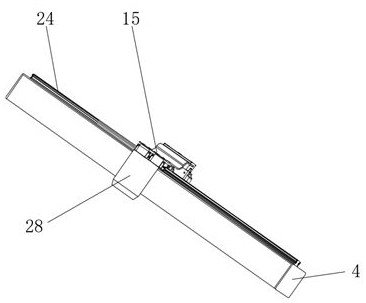

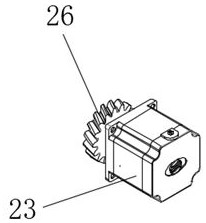

[0026] see Figure 1-4 , the present invention provides a technical solution: an electronic bag leather cutting device with debris collection function, comprising a first plate 2, the upper surface of the first plate 2 is fixedly connected with a second plate 10, the second The upper surface of the plate body 10 is symmetrically hinged with two pressure plates 8 through pin shafts, the front surfaces of the two pressure plates 8 are fixedly connected with the second handle 9, and the inner side wall of the first plate body 2 is symmetrically provided with four square grooves 31, four The inner side walls of each square groove 31 are all slidably connected with rod bodies 20, and one end of the four rod bodies 20 respectively penetrates through the inner side wall top of the square groove 31 and the lower surface of the second plate body 10 and is fixedly connected with the second housing 13, four The other end of the rod body 20 all runs through the bottom of the inner side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com