Double-colored strip sheath and its extrusion die

A technology of extrusion die and color bar, applied in the direction of instrument, fiber mechanical structure, optics, etc., can solve the problems of increased color bar, poor versatility, limited diversity of color bar forms, etc., to achieve the effect of improving recognition and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

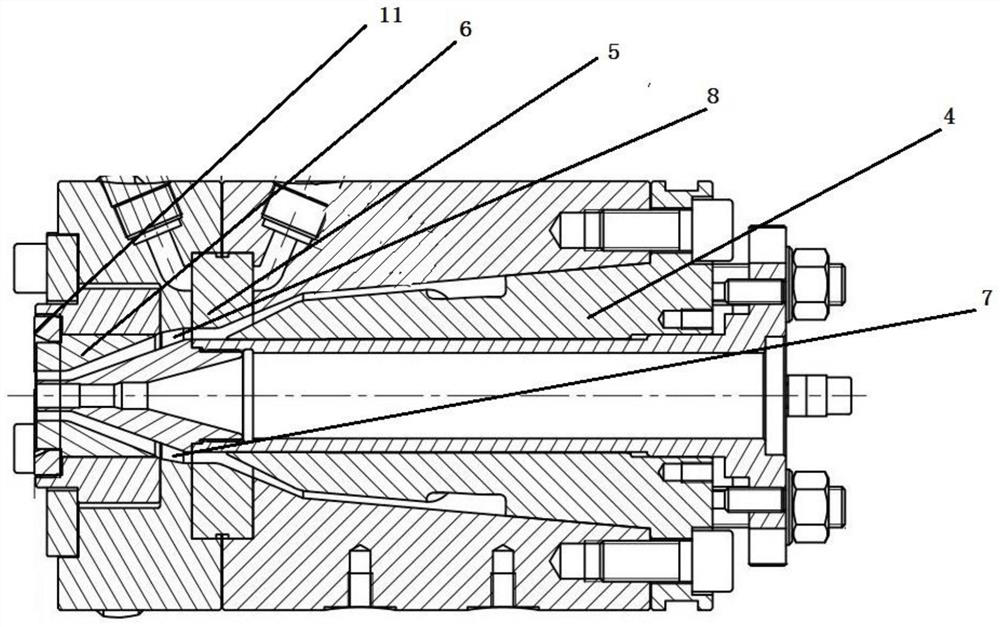

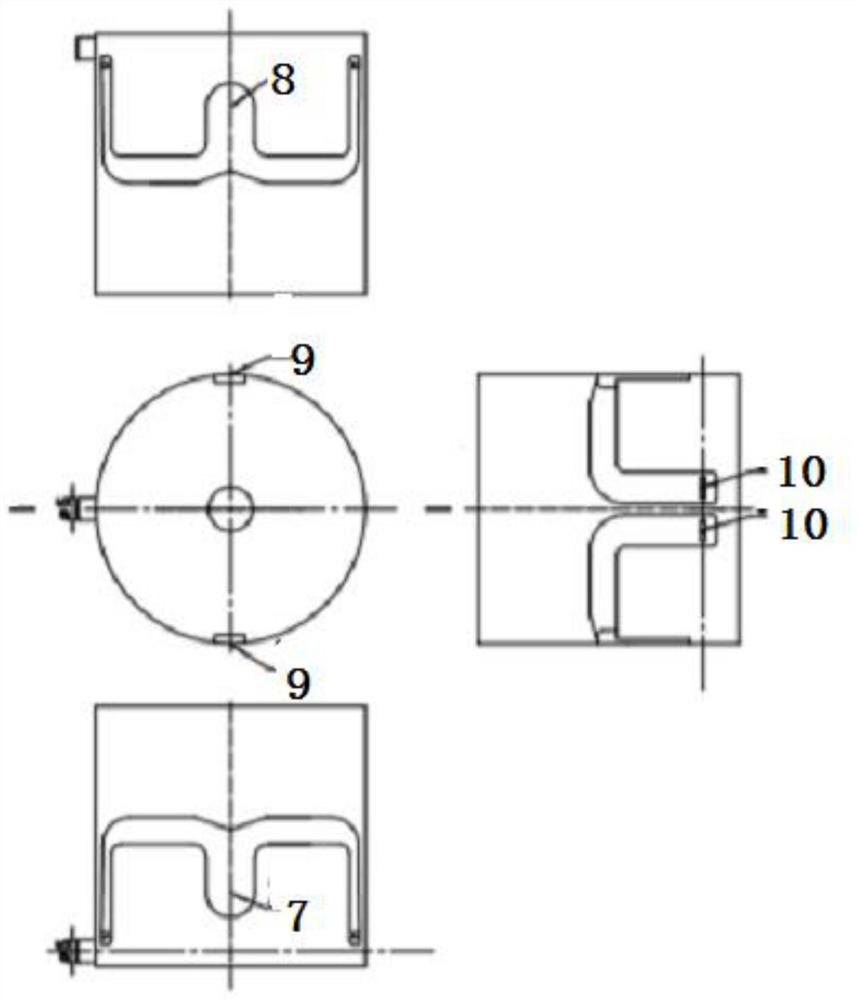

[0022] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

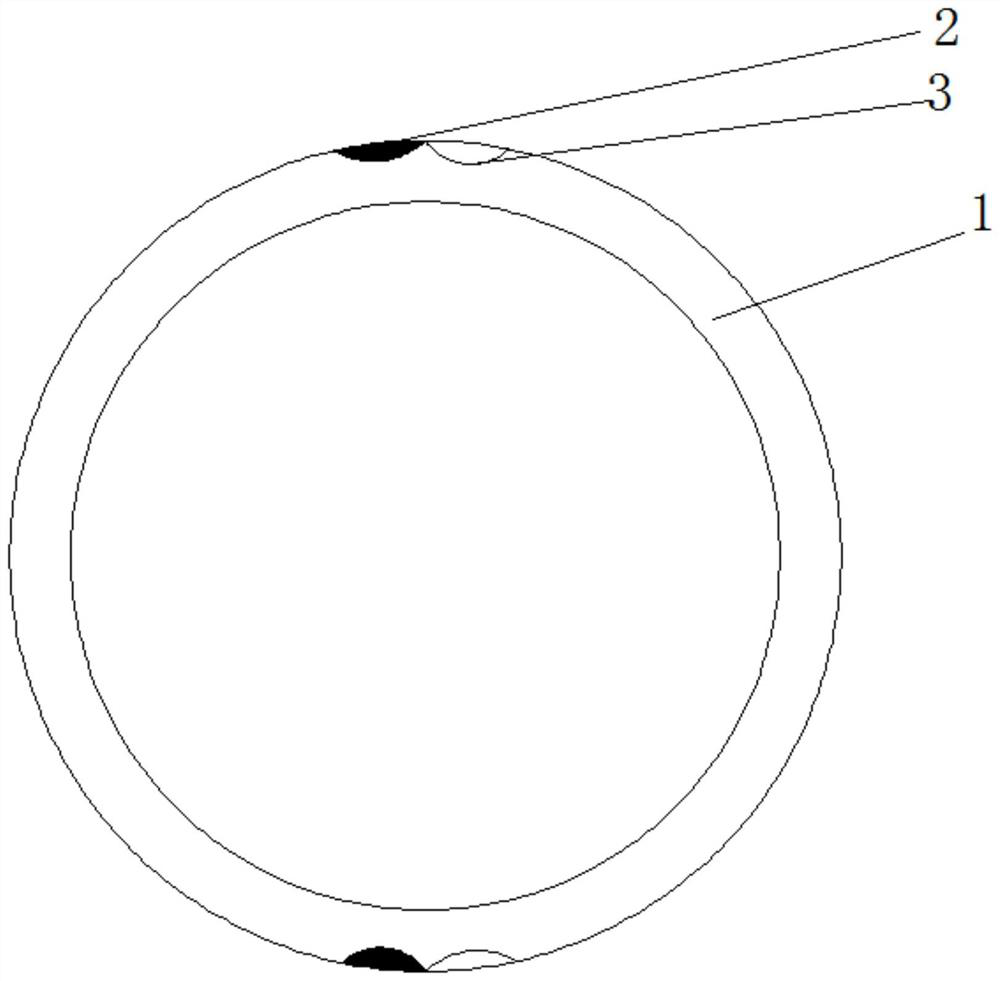

[0023] refer to figure 1 As shown, an embodiment of the double-isochromatic strip sheath of the present invention includes a tubular sheath body 1 for wrapping outside the cable core, and two pairs of parallel-arranged double-isolated Color bars, the double-heterochromatic bars include two first color bars 2 and second color bars 3 that are arranged in parallel and have different colors, two pairs of double-heterogeneous colors are symmetrically arranged, and two pairs of double-heterochromatic color bars are two first color bars. 2 is arranged on one side, and two second color bars 3 are arranged on one side.

[0024] Specifically, the wall thickness of the first color bar 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com