Automatic cooling demolding system for plastic mold

An automatic cooling and plastic mold technology, which is applied in the field of plastic molds, can solve the problems of difficult plastic mold release, etc., and achieve the effect of fast cooling and hardening, easy removal, and reduced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

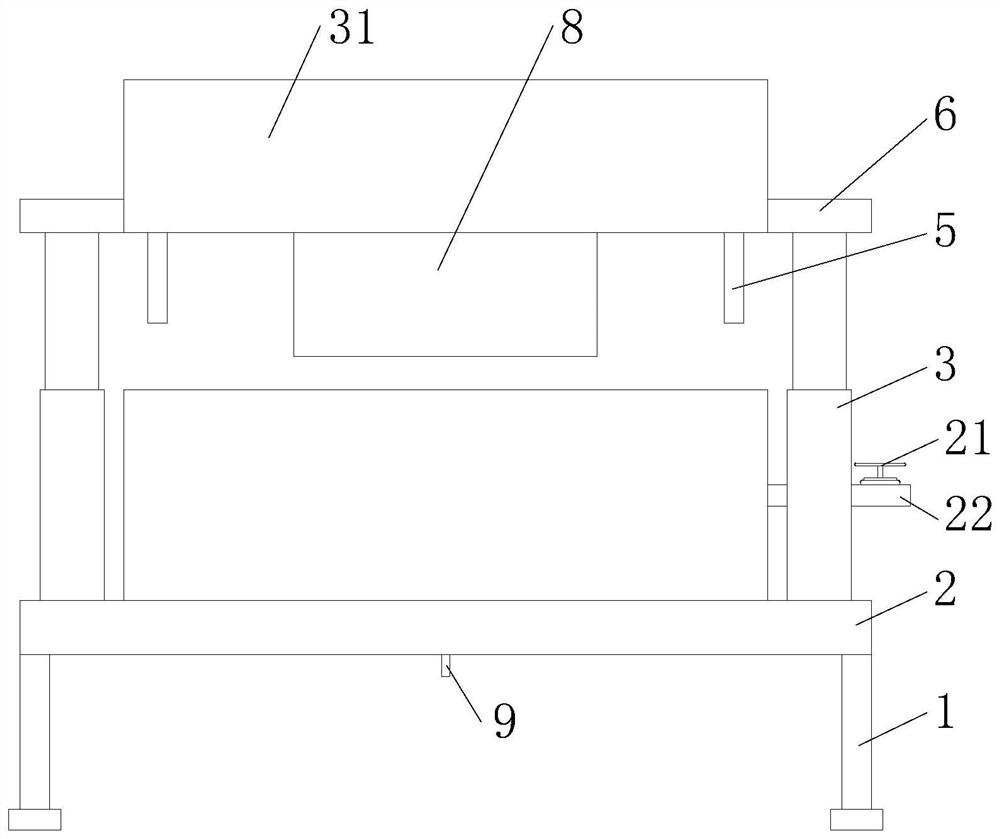

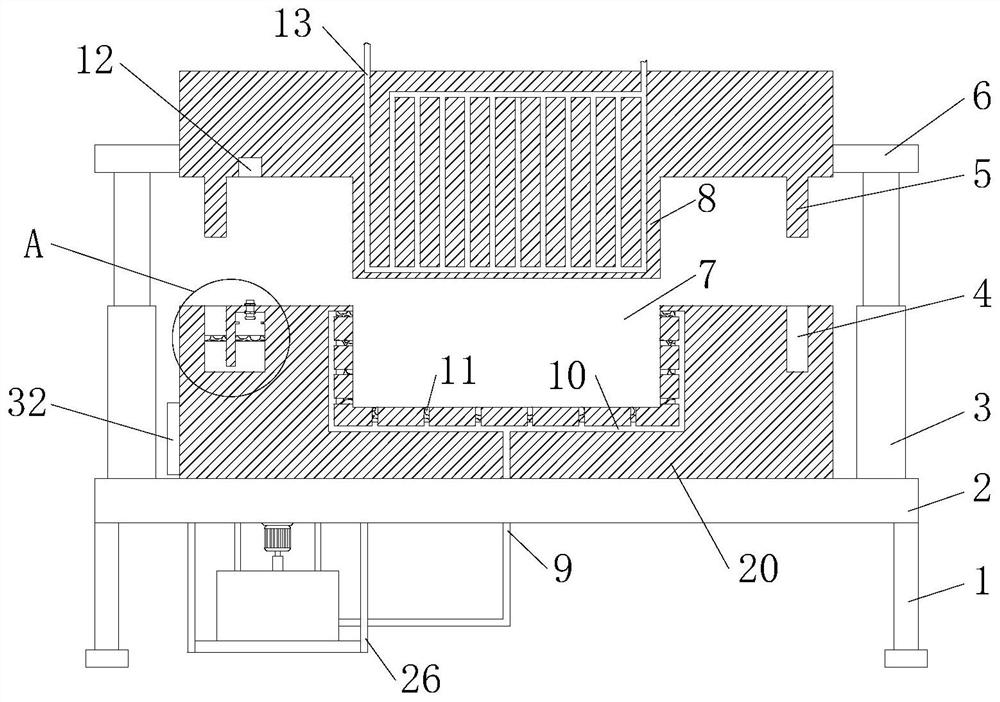

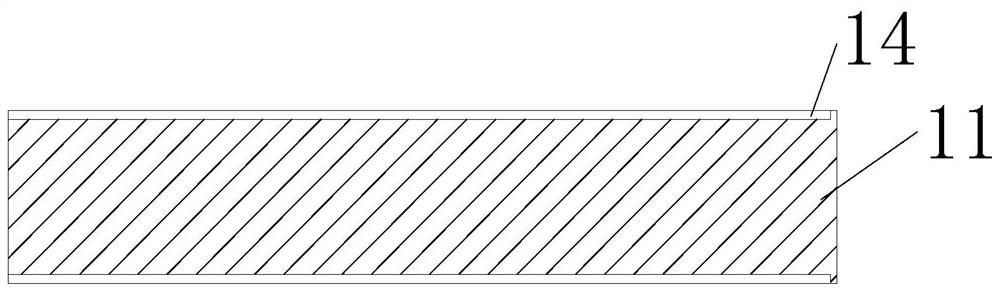

[0030] Such as Figure 1-5 As shown, the embodiment of the present invention provides an automatic cooling and demoulding system for plastic molds, including a working platform 2, a forming mold 20 is fixedly connected to the center of the upper surface of the working platform 2, and a cooling pipe 13 is arranged above the forming mold 20. Mold 20, a forming cavity 7 is provided on the upper surface of the forming mold 20, the side wall and the inner bottom wall of the forming cavity 7 are slidingly connected with a stripping module 11, and the forming mold 20 is located at the position of the stripping module 11 and is provided with an oil discharge pipe 10, and the oil discharge pipe 10 and the dismounting module 11 at the corresponding position are set through. The middle part of the lower surface of the forming mold 20 is fixedly connected with the oil delivery pipe 9. The oil delivery pipe 9 is connected with the oil discharge pipe 10. A compression mold 31 is arranged abo...

Embodiment 2

[0037] The difference between the present embodiment and the first embodiment is that the limit block 23 and the proximity switch 17 are replaced by pressure-sensing switches, which makes it inconvenient to achieve the purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com