Distributed cooperative control system for production workshop

A production workshop and collaborative control technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve problems such as regulation, inability to slow down the progress of the assembly line, and affect the work progress of the assembly line, achieving high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

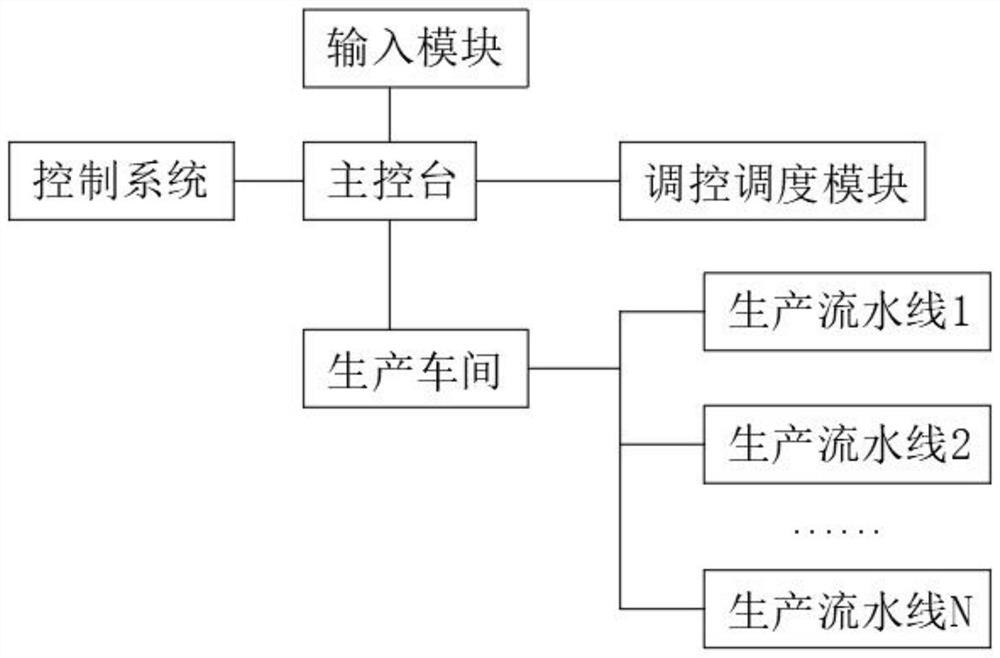

[0043] see figure 1 , a distributed collaborative control system for production workshops, including a main console, the console of the main console is provided with an input module for issuing instructions, the main console is connected with the signal of the production workshop, and the production workshop includes multiple production The assembly line, multiple production lines are equipped with mutually independent sub-control modules, multiple self-control modules are connected to the main console signal, the main console is also connected to the control and scheduling module, and the control and scheduling module includes the input module signal The connected sub-control modules, multiple cameras installed on multiple production line stations, and the dispatching robot 1, the cameras use high-definition cameras, which make the progress monitoring screen of the control dispatching module for multiple stations on the production line clearer and convenient. Timely discover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com