Microfluidic ultrasonic electrochemical on-chip laboratory analysis platform

A sonoelectrochemical and laboratory technology, which is applied in the direction of laboratory appliances, laboratory containers, and electrochemical variables of materials, to achieve the effects of improved sensitivity, good fastness, and precise thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

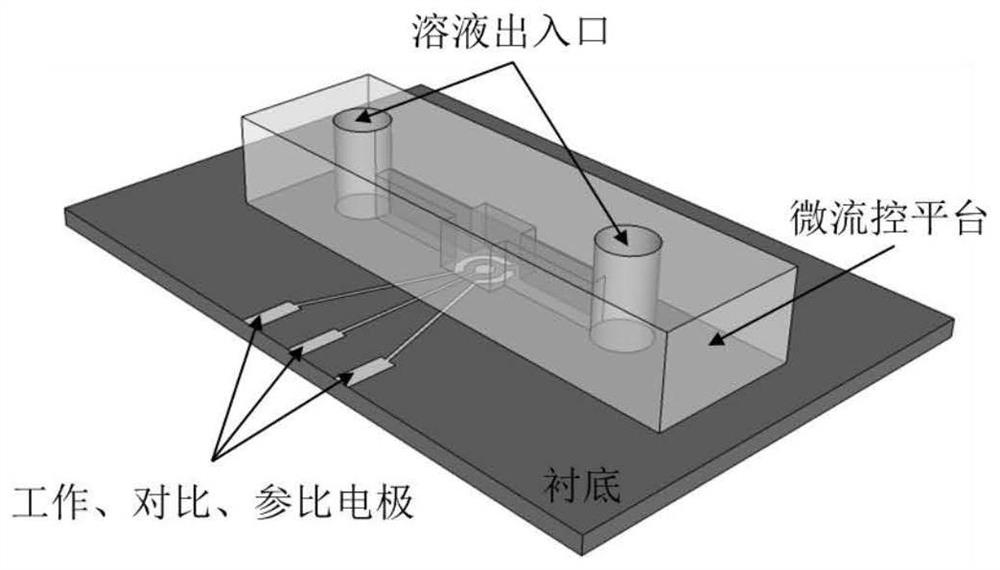

[0065] Such as Figure 4 with 14As shown, a microfluidic sonoelectrochemical laboratory-on-chip analysis platform includes: an electrochemical sensor chip 6 and a microfluidic assembly 4 and a supporting substrate 2 arranged in parallel, an electrochemical sensor chip 6, a microfluidic assembly 4 and the support substrate 2 are arranged in sequence from top to bottom, wherein a micro-ultrasonic device 2-1 is arranged on the top surface of the support substrate 2, and a through hole is formed on the micro flow channel assembly 4, and the height of the through hole is 10 μm to 10 mm. The width of the through hole is 1mm˜10mm. The hole wall of the through hole forms a cavity 4-3 (that is, up and down) that is open at the top and bottom. The cavity 4-3 is used for ultrasonic electrochemical detection, and the cavity 4-3 is connected with microfluidic ultrasonic testing. The electrochemical on-chip laboratory analysis platform communicates with the outside, so that the liquid to ...

Embodiment 2

[0071] On the basis of Example 1, such as Figure 5 As shown, a liquid inlet chamber 4-1 and a liquid outlet chamber 4-2 are formed in the microchannel assembly 4, the liquid inlet chamber 4-1 communicates with the chamber body 4-3 through a first channel 4-4, and the liquid outlet chamber 4-2 communicates with the chamber 4-3 through a second channel 4-5, and the chamber 4-3 communicates with the microfluidic sonoelectrochemical laboratory-on-chip analysis platform through the liquid inlet chamber 4-1 and the liquid outlet chamber 4-2 The outside is connected.

[0072] The liquid inlet chamber 4-1, the liquid outlet chamber 4-2, the chamber body 4-3, the first channel 4-4 and the second channel 4-5 jointly form a micro flow channel, and the first channel 4-4 and the second channel 4 -5 have a width of 10 μm to 1 mm, the lengths of the first channel 4-4 and the second channel 4-5 are respectively 2 mm to 2 cm, and the liquid inlet chamber 4-1 and the liquid outlet chamber 4-2...

Embodiment 3

[0075] On the basis of embodiment 2, it also includes: an electrochemical sensor area limiting assembly 5 parallel to the micro flow channel assembly 4, a first opening 5-1 is formed on the electrochemical sensor area limiting assembly 5, the first opening 5-1 Set opposite to the sensing area of the three electrodes, the electrochemical sensor chip 6 and the micro-ultrasonic device 2-1 are set in parallel or non-parallel, wherein:

[0076] When arranged in parallel, the electrochemical sensor area limiting component 5 can determine the area of the sensing area of the three electrodes exposed in the cavity 4-3, and the liquid to be measured can pass through the first opening 5-1 and the sensing area of the three electrodes. Sensing area contact, the size of the first opening 5-1 is greater than or equal to the size of the sensing area of the three electrodes and less than or equal to the size of the cross-section of the through hole, such as Figure 8 As shown, the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com