A filter device for chemical waste liquid with split flow and anti-clogging

A filter device and anti-clogging technology, which is applied in the chemical industry, can solve the problems of inability to guarantee the cleaning effect, blockage of the filter screen, unfavorable sedimentation of chemical waste liquid particles, etc., and achieve the effect of convenient backwashing operation and slowing down the flow rate of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

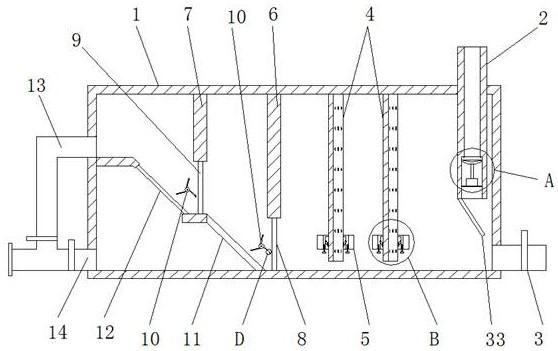

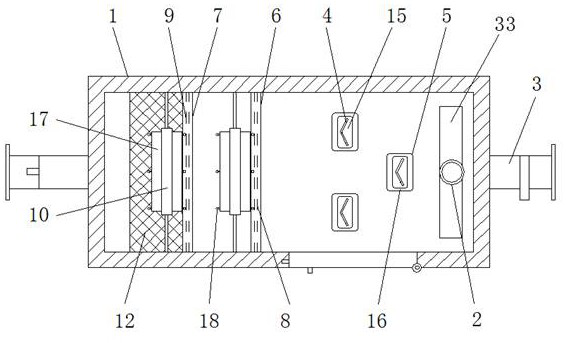

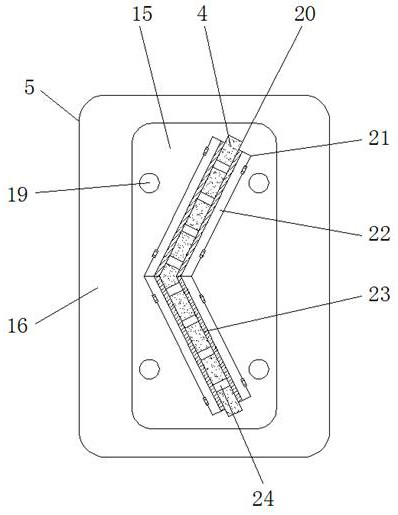

[0030] see Figure 1-10 , the present invention provides a technical solution: a chemical waste liquid filter device with shunt flow and anti-clogging, including filter device body 1, waste liquid pipe 2, waste water pipe 3, splitter plate 4, cleaning sleeve 5, first barrier plate 6 , the second barrier plate 7, the first filter screen 8, the second filter screen 9, the vibrating roller 10, the guide plate 11, the third filter screen 12, the cleaning pipe 13, the liquid outlet pipe 14, the sliding block 15, the floating ball 16 , rotating blade 17, hitting ball 18, support frame 19, chute 20, deflection groove 21, deflection plate 22, cleaning brush 23, diversion hole 24, sealing tray 25, support rod 26, sealing groove 27, sealing protrusion 28, Limiting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com