Double-channel airtight packaging structure of flip-chip and process of double-channel airtight packaging structure

A packaging structure and airtight technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of large thermal resistance, small chip contact area, poor heat dissipation efficiency, etc., to reduce the overall thermal resistance and shorten the working time , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

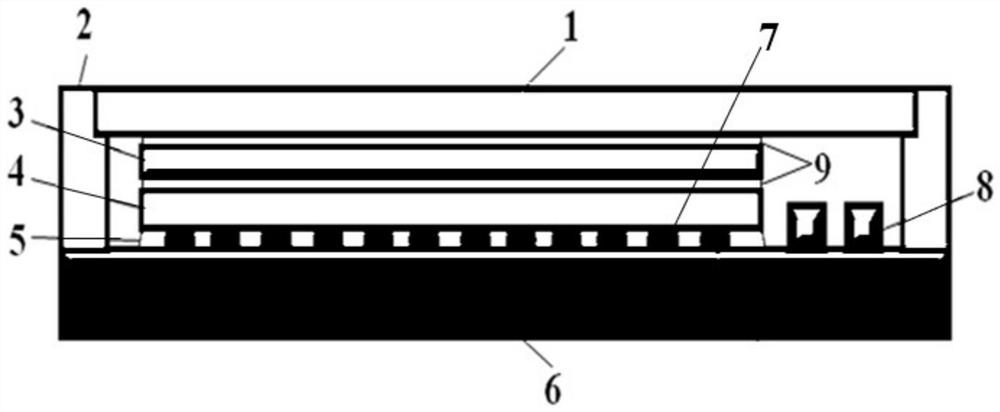

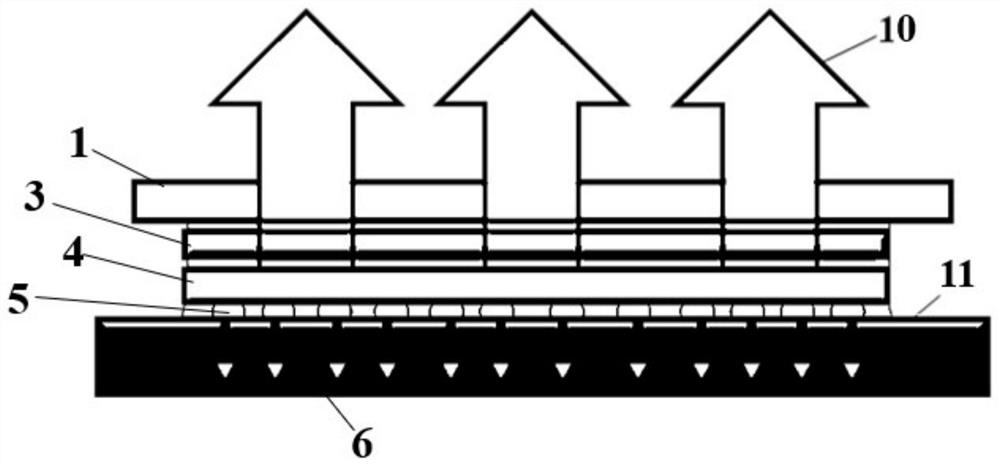

[0039] Such as figure 1 As shown, the double-channel hermetic packaging structure includes a cover plate 1, a casing 6 and a sealing ring 2 installed on the casing 6, and a flip chip 4 and a heat sink 3 are installed in the sealing ring 2 , the cover plate 1 is installed on the top of the heat sink 3, the heat sink 3 is installed on the top of the flip chip 4, and the flip chip 4 is installed on the top of the shell 6, and the heat sink 3 is connected with the cover plate 1 and the flip chip A heat dissipation layer is arranged between the 4.

[0040] Concrete preparation process is as follows:

[0041] S1: first install the sealing ring 2 on the casing 6, temporarily fix the cover plate 1 on the upper part of the sealing ring 2, and fix the flip chip 4 on the top of the casing 6;

[0042] S2: According to the vertical height difference between the upper surface of the flip chip 4 and the bottom surface of the cover plate 1, prepare the heat sink 3 according to the vertical ...

Embodiment 2

[0047] Prepare the cavity packaging structure, prepare a stepped sealing ring 2 on the shell 6, both the cover plate 1 and the sealing ring are made of nickel-plated Kovar material, and the fit gap between the cover plate 1 and the sealing ring 2 is ≤0.1 mm, the surface height difference is less than or equal to 0.5mm, and a flip chip 4 with a size of 20mm×20mm is welded inside the tube shell 6 . Package according to the following steps:

[0048] (1) Using optical equipment to measure the vertical height difference between the upper surface of the flip-chip 4 and the step on the sealing ring 2 where the cover plate 1 is pre-placed;

[0049] (2) Prepare an AlN ceramic sheet whose thickness is determined according to the measured value of the vertical height difference between the upper surface of the flip-chip 4 and the step of the sealing ring 2, which is 50 μm-200 μm smaller than the above-mentioned vertical height difference;

[0050] (3) Cut the AlN ceramic chip into a hea...

Embodiment 3

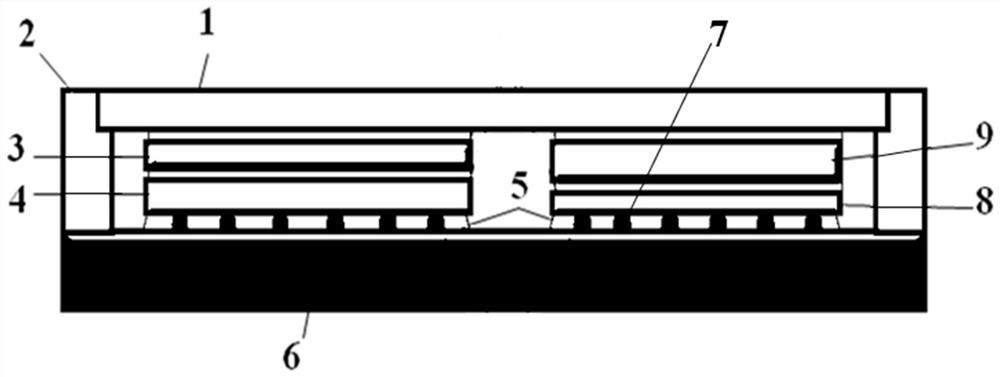

[0060] When processing two chips at the same time, if the thickness of the two chips is inconsistent, such as figure 2 As shown, the cavity packaging structure is prepared. A stepped gold-plated aluminum alloy sealing ring 2 is prepared on the shell 6. The cover plate 1 is made of an aluminum alloy with excellent mechanical properties and thermal conductivity, and the surface is plated with gold. The cover plate The matching clearance and surface height difference between 1 and sealing ring 2 meet the requirements, and there are two flip-chip bare chips with dimensions of 15mm×18mm and 10mm×15mm respectively welded in the cavity. Package according to the following steps:

[0061] (1) Using optical equipment to measure the height difference between the upper surface of the two flip-chips 4 and the steps of the sealing ring 2;

[0062] (2) Prepare an Al-SiC sheet heat sink 3, the thickness of which is determined according to the measured value of the height difference between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com